Radiation resistant and ultraviolet filtering film for space optic quartz glass and manufacturing method thereof

A quartz glass, radiation-resistant technology, applied in chemical instruments and methods, optics, optical components, etc., can solve problems such as complex process, high cost, environmental pollution, etc., achieve stable process technology, improve radiation resistance performance, solve The effect of insufficient steepness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

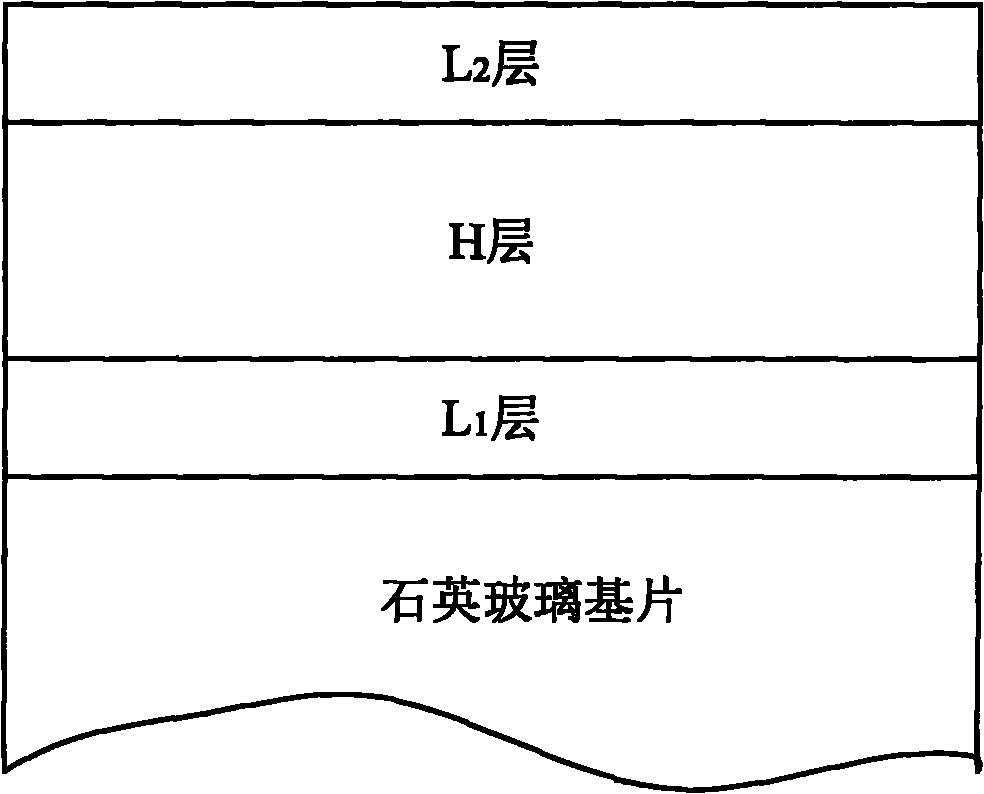

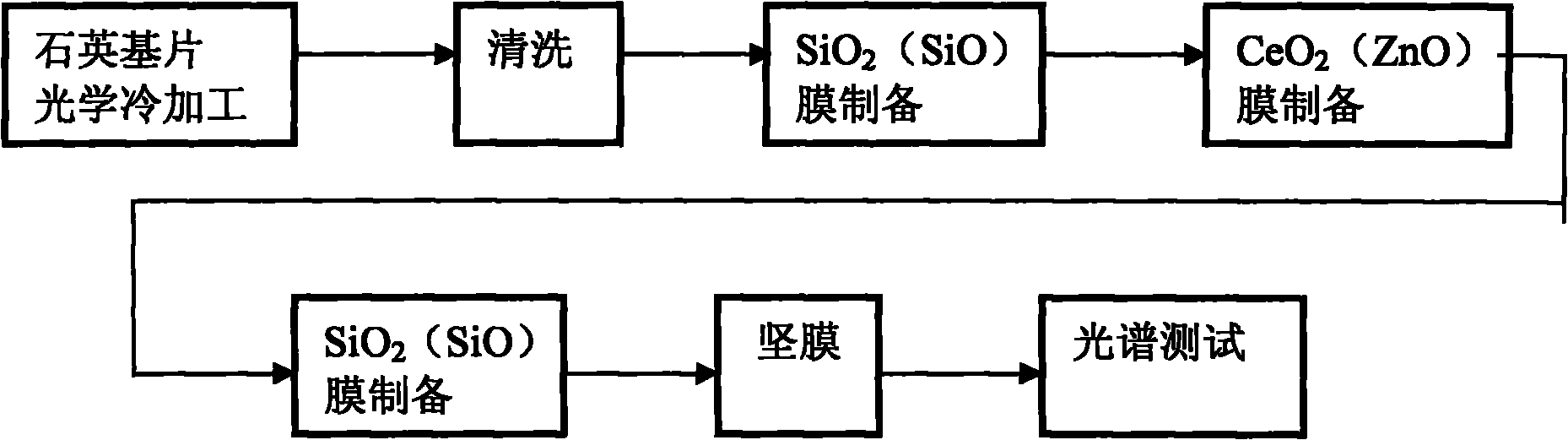

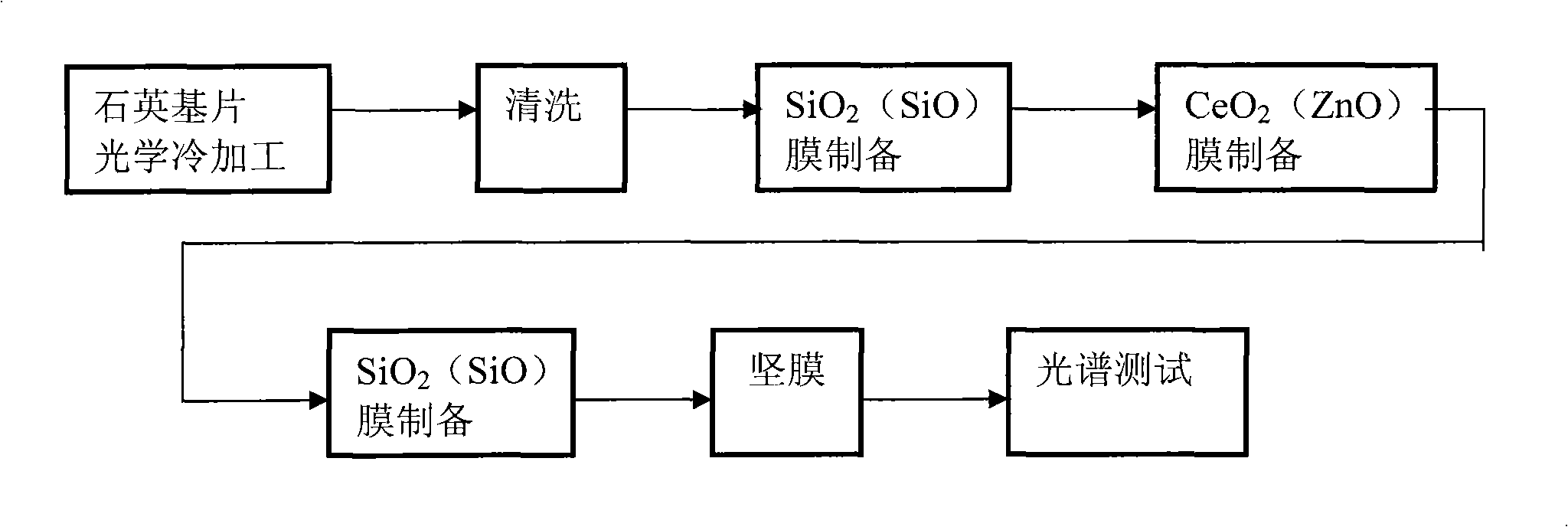

Image

Examples

Embodiment 1

[0079] 1. Process and shape the ordinary quartz glass substrate according to the requirements;

[0080] 2. Cleaning treatment: Wipe the substrate with calcium carbonate, rinse it with water, soak it in glass washing solution for more than 2 hours, take it out and rinse it with deionized water, dehydrate it with absolute ethanol, add 50% ethyl ether with 50% absolute ethanol The lotion wipes clean;

[0081] This example adopts the glass washing liquid of 55g potassium dichromate, 100ml water and 1000ml concentrated sulfuric acid configuration, pH value<3.

[0082] 3. On a quartz substrate, SiO was prepared by vacuum thermal evaporation 2 The film process is as follows:

[0083] a) Place the substrate in a vacuum chamber and heat to 110°C±10°C;

[0084] b) When the vacuum reaches 2×10 -3 When the Ha is below, the evaporation work is started, and the evaporation material is preheated, pre-evaporated, and evaporated; the film thickness is required to be 60-62nm;

[0085] c) E...

Embodiment 2

[0099] 1. Process and shape the ordinary quartz glass substrate according to the requirements;

[0100] 2. Cleaning treatment: Wipe the substrate with calcium carbonate, rinse it with water, soak it in glass washing solution for more than 2 hours, take it out and rinse it with deionized water, dehydrate it with absolute ethanol, add 50% ethyl ether with 50% absolute ethanol The lotion wipes clean;

[0101] 3. On the quartz substrate, SiO was prepared by magnetron sputtering 2 The film process is as follows:

[0102] a) the substrate is placed in a vacuum chamber, and the temperature of the substrate is the temperature of the vacuum chamber;

[0103] b) When the vacuum reaches 2×10 -3 Start sputtering coating work when Ha is below, the vacuum chamber is filled with argon and the vacuum degree is stabilized at 8×10 -1 ~2×10 0 In the state of Ha, the target is preheated, pre-sputtered, and sputtered; the film thickness is required to be 60-62nm;

[0104] c) End evaporation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com