Selenium yeast for feeds and preparation method thereof

A technology of selenium yeast and feed, applied in the field of selenium yeast for feed and its preparation, can solve the problems of lack of scale production, unrealized production, lack of optimal conditions for selenium-enriched fermentation, etc., and achieve low cost and avoid simple selenium The effect of generating and improving the conversion rate of selenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

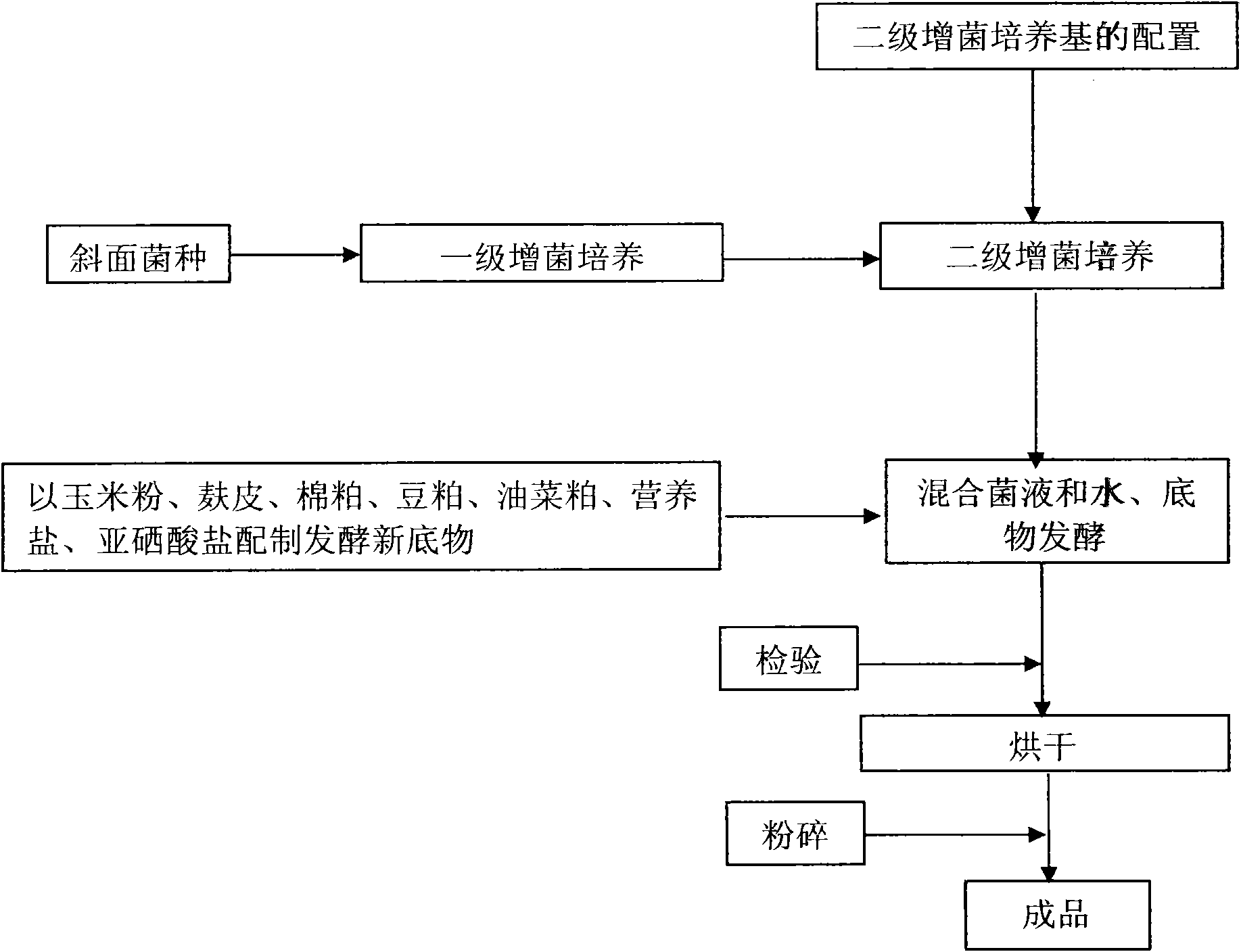

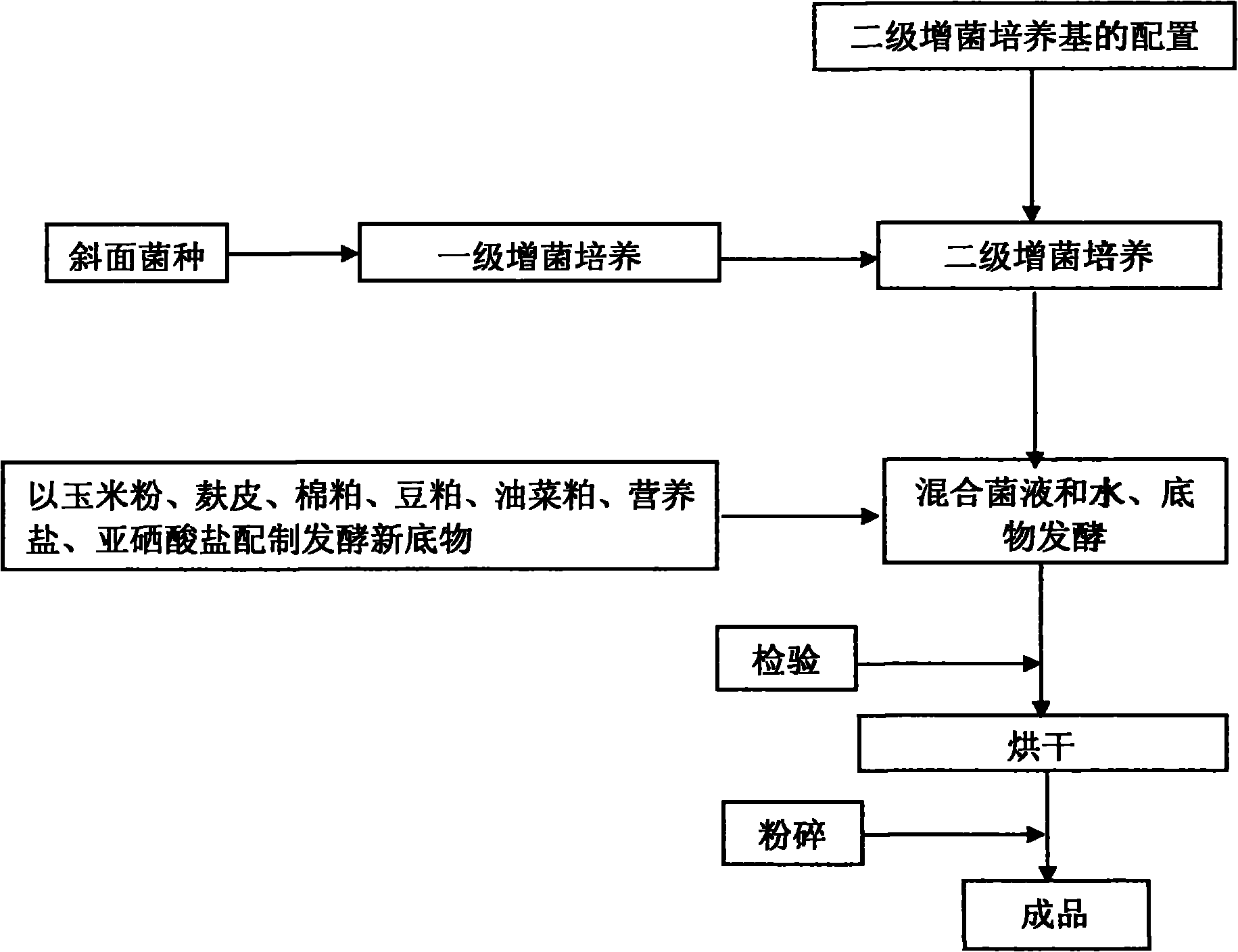

[0035] Prepare the selenium yeast of the present embodiment according to the following method, see also figure 1 The flow shown:

[0036] Primary enrichment culture: Pick five rings of brewer's yeast on the inclined surface of the test tube and inoculate them in 300ml wort enrichment medium (the wort enrichment medium consists of 130g wort plus 1000ml distilled water, and the sugar content is adjusted to 8 waves Lin, adjust the pH to 6.0, sterilize at 121°C for 20 minutes, measure 300ml) in an Erlenmeyer flask (500ml capacity of the Erlenmeyer flask), plug the bottle stopper, and wrap it with a parafilm, at 30°C, 120 Shake for 24 hours under the condition of rev / min for primary enrichment culture;

[0037] Secondary enrichment culture: 50kg secondary seed culture medium (by 8 weight portions of corn flour, 2 weight portions of bran, nutrient salt (made by mixing potassium dihydrogen phosphate, ammonium sulfate, glucose according to 1.5:5:1) ) 0.75 parts by weight, add 39.25 ...

Embodiment 2

[0041] Prepare the selenium yeast of the present embodiment according to the following method:

[0042] Primary enrichment culture: Inoculate the brewer's yeast on the inclined surface of the test tube with a ratio of about 60ml per ring into the wort enrichment medium (add 7.5 times the volume of distilled water from the wort, adjust the sugar content to 6 Pauline, adjust the pH to 6.5, sterilized at 120°C for 25 minutes) in a Erlenmeyer flask, stoppered, wrapped with a parafilm, and shaken at 30°C and 120 rpm for 24 hours for primary enrichment culture ;

[0043] Secondary enrichment culture: 100kg secondary seed culture medium (by 18 weight portions of corn flour, 4 weight portions of bran, nutrient salt (made by mixing potassium dihydrogen phosphate, ammonium sulfate, glucose according to 1.5:5:1) ) 1.5 parts by weight, add 76.5 parts by weight of water and mix evenly, adjust the pH to 4.5, and sterilize at 121°C for 30 minutes to make) heat to 60°C, add 8U of α-amylase w...

Embodiment 3

[0047] Prepare the selenium yeast of the present embodiment according to the following method:

[0048] Primary enrichment culture: Inoculate the brewer's yeast on the inclined surface of the test tube in the ratio of 50ml per ring into the wort enrichment medium (add 8 times the volume of distilled water from the wort, adjust the sugar content to 10 Pauline, and adjust the pH to 6.0, made by sterilizing at 121°C for 20 minutes), stopper the bottle, wrap it with a parafilm, shake it at 30°C and 150 rpm for 28 hours for primary enrichment culture;

[0049] Secondary enrichment culture: 50kg secondary seed medium (by 15 parts by weight of corn flour, 5 parts by weight of bran, nutrient salt (made by mixing potassium dihydrogen phosphate, ammonium sulfate, glucose according to 1.5:5:1) ) 1.5 parts by weight, add 78.5 parts by weight of water and mix evenly, adjust the pH to 4.0, and sterilize at 121°C for 20 minutes to make) heat to 55°C, add 8U of α-amylase with enzyme activity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com