Preparation method of cellulose-based high-water-absorption high-water-retention resin

A water-retaining resin and cellulose technology, which is used in fiber raw material processing, textile and papermaking, and bulk chemical production. , Good salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

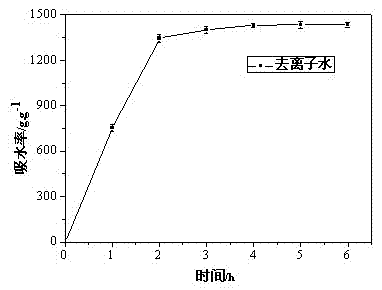

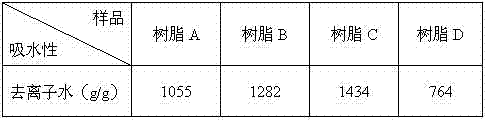

Image

Examples

Embodiment 1

[0021] Embodiment 1: (below all mass percent meter)

[0022] (1) Cellulose extraction: crush flax waste yarn, place it in 1% NaOH solution at a bath ratio of 1:20 (m / v), boil at 100 °C for 1 h, wash with hot water until neutral, and place in In 1.5% NaOH / 0.4% sodium polyphosphate / 0.4% sodium silicate mixed solution, boil at 100 ℃ for 2 h, wash with hot water until neutral, and dry. income α -97% cellulose, it is pulverized, passed through a 40 mesh sieve, and set aside.

[0023] (2) Cellulose dissolution: Take 1 g of crushed flax cellulose and immerse in 25 mL of pre-cooled 6% sodium hydroxide / 12% urea aqueous solution at -20 °C, freeze at -20 °C for 60 min, and mechanically stir at room temperature for 5 min , to obtain a homogeneous and transparent cellulose solution.

[0024] (3) Homogeneous polymerization: Stir the transparent cellulose solution obtained in (2) under nitrogen protection for 30 minutes, and heat it to 70 °C, add 0.1 g of initiator ammonium persulfate (A...

Embodiment 2

[0026] (1) Cellulose extraction: crush flax waste yarn, place it in 1% NaOH solution at a bath ratio of 1:20 (m / v), boil at 100 °C for 1 h, wash with hot water until neutral, and place in In 1.5% NaOH / 0.4% sodium polyphosphate / 0.4% sodium silicate mixed solution, boil at 100 ℃ for 2 h, wash with hot water until neutral, and dry. income α -97% cellulose, it is pulverized, passed through a 40 mesh sieve, and set aside.

[0027] (2) Cellulose dissolution: immerse 1 g of crushed flax cellulose in 25 mL of 7% sodium hydroxide / 10% urea aqueous solution pre-cooled at -20 °C, freeze at -20 °C for 60 min, and mechanically stir at room temperature for 5 min , to obtain a homogeneous and transparent cellulose solution.

[0028] (3) Homogeneous polymerization: Stir the transparent cellulose solution obtained in (2) under nitrogen protection for 30 min, and heat to 70 °C, add 0.1 g of initiator APS, and add 5 g of AA after 15 min (neutralization degree 70%), 1 g AM monomer and 0.03 g cr...

Embodiment 3

[0030] (1) Cellulose extraction: crush flax waste yarn, place it in 1% NaOH solution at a bath ratio of 1:20 (m / v), boil at 100 °C for 1 h, wash with hot water until neutral, and place in In 1.5% NaOH / 0.4% sodium polyphosphate / 0.4% sodium silicate mixed solution, boil at 100 ℃ for 2 h, wash with hot water until neutral, and dry. income α -97% cellulose, it is pulverized, passed through a 40 mesh sieve, and set aside.

[0031] (2) Cellulose dissolution: Take 1 g of crushed flax cellulose and immerse in 25 mL of pre-cooled 10% sodium hydroxide / 4% urea aqueous solution at -20 °C, freeze at -20 °C for 60 min, and mechanically stir at room temperature for 5 min , to obtain a homogeneous and transparent cellulose solution.

[0032] (3) Homogeneous polymerization: Stir the transparent cellulose solution obtained in (2) under nitrogen protection for 30 min, and heat to 60 °C, add 0.1 g initiator APS, and add 4 g AA after 15 min (neutralization degree 70%) and 1 g AM monomer and 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com