Method for controllable synthesis of zinc oxide nanotube and/or nanowire

A technology of zinc oxide nanotubes and nanowires, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, single crystal growth, etc., can solve the problem of low cost, achieve low cost, simple method, and easy scale Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The synthesis of embodiment 1 zinc oxide nanotube

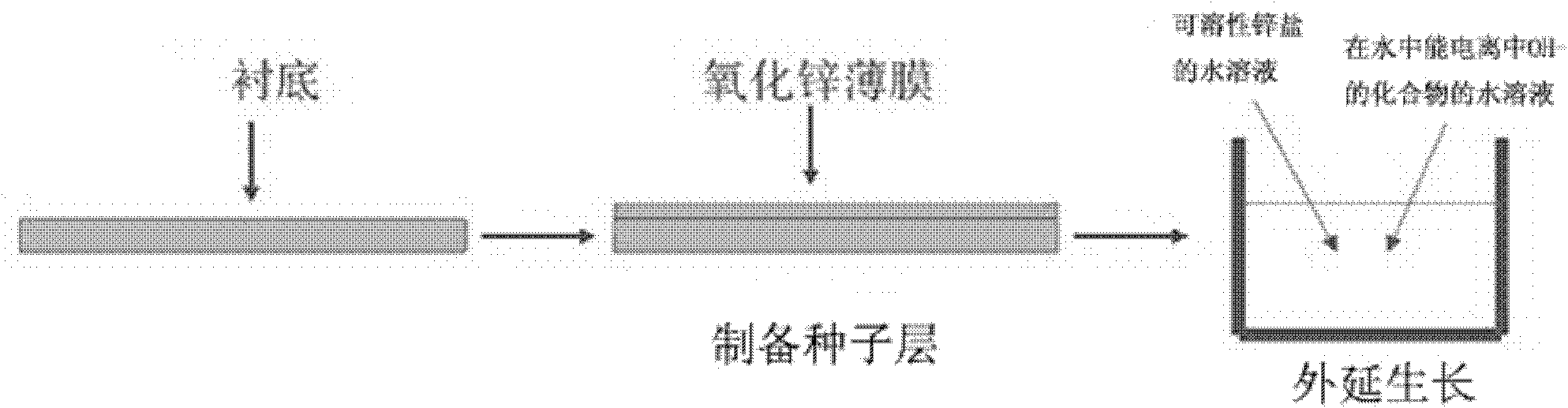

[0045] The schematic diagram of the experimental steps of wet chemical epitaxial growth of zinc oxide nanotubes in this embodiment is as followsfigure 1 shown.

[0046] (1) Preparation of a seed layer In this embodiment, an intrinsic silicon wafer [Si substrate (100)] is used as a growth substrate, and the silicon wafer is cleaned by a standard cleaning process. Then a layer of zinc oxide film with a thickness of about 450nm was sputtered on the growth substrate by magnetron sputtering as a seed layer for epitaxial growth.

[0047] Magnetron sputtering process parameter: present embodiment is sputtering source with zinc oxide (ZnO, purity is 99.99%) target material, during magnetron sputtering, the pressure of studio is set as 1Pa, and the flow rate of argon is 20sccm, sputtering The injection time is 30min. The zinc oxide annealing step is determined by the degree of crystallization of the film after sputtering. If...

Embodiment 2

[0051] Embodiment 2 Synthesis of zinc oxide nanotube and nanowire mixture

[0052] The schematic diagram of the experimental steps of wet chemical epitaxial growth of zinc oxide nanowires in this embodiment is as follows figure 1 Shown (where the method of sputtering is changed to the method of sol-gel spin coating).

[0053] (1) Preparation of the seed layer A layer of zinc oxide thin film was coated on the glass as the seed layer. The zinc oxide seed layer can be prepared by magnetron sputtering, and this example is prepared by sol-gel method. Firstly, 5mM zinc acetate solution and 20mM sodium hydroxide solution, followed by zinc acetate solution and sodium hydroxide solution are mixed with a volume ratio of 9:1 and placed on a magnetic stirrer for 0.5h, during which Constant temperature at 60°C. Spin coating on the growth substrate again by spin coating method (1000r / min rotation speed). Finally, anneal at 500° C. for 3 hours in a high-temperature box furnace to obtain ...

Embodiment 3

[0056] The synthesis of embodiment 3 zinc oxide nanowires

[0057] The schematic diagram of the experimental steps of wet chemical epitaxial growth of zinc oxide nanowires in this embodiment is as follows figure 1 shown.

[0058] (1) Preparation of a seed layer In this embodiment, an intrinsic silicon wafer [Si substrate (100)] is used as a growth substrate, and the silicon wafer is cleaned by a standard cleaning process. Then, a layer of 450nm zinc oxide film was sputtered on the silicon wafer by magnetron sputtering as a seed layer for epitaxial growth.

[0059] Magnetron sputtering process parameter: present embodiment is sputtering source with zinc oxide (ZnO, purity is 99.99%) target material, during magnetron sputtering, the pressure of studio is set as 1Pa, and the flow rate of argon is 20sccm, sputtering The injection time is 30min. The zinc oxide annealing step is determined by the degree of crystallization of the film after sputtering. If the degree of crystalliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com