Lactobacillus fermentum and application thereof

A technology of fermenting Lactobacillus and bacteria agent, applied in the direction of application, bacteria, antibacterial drugs, etc., can solve the problems of unstable product quality, insufficient number of viable bacteria, low digestibility, etc., to enhance non-specific immune function and promote animal health. Effects of growth, promotion of digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1. Isolation and identification of Lactobacillus fermentum (Lactobacillus fermentum) HAFI5007

[0066] The lactobacillus fermentum of the invention is extracted, separated, screened and purified from pig gastrointestinal mucosa.

[0067] (1) Isolation and purification of Lactobacillus fermentum

[0068] 1.1 Test material

[0069] Take healthy piglet gastrointestinal mucosa 5cm 2 (stomach, duodenum, jejunum, ileum, cecum, and colon), in a sterile cup, rinse the chyme on the mucosa with sterile saline, immerse the mucosa in a beaker containing 15 mL of HEPES buffer, and use forceps After shaking the mucosa back and forth for 5 minutes, the supernatant was obtained.

[0070] 1.2 Medium

[0071] 1.2.1 Medium of Rogosa SL agar

[0072] Tryptone 10g, beef extract 10g, yeast extract powder 5g, glucose 10g, arabinose 5g, sucrose 5g, sodium acetate 15g, sodium citrate 2g, potassium dihydrogen phosphate 6g, magnesium sulfate heptahydrate 0.58g, manganese sulfate tetr...

Embodiment 2

[0144] Example 2, Research on the biological characteristics of Lactobacillus fermentum (Lactobacillus fermentum) HAFI5007 CGMCC No.4648

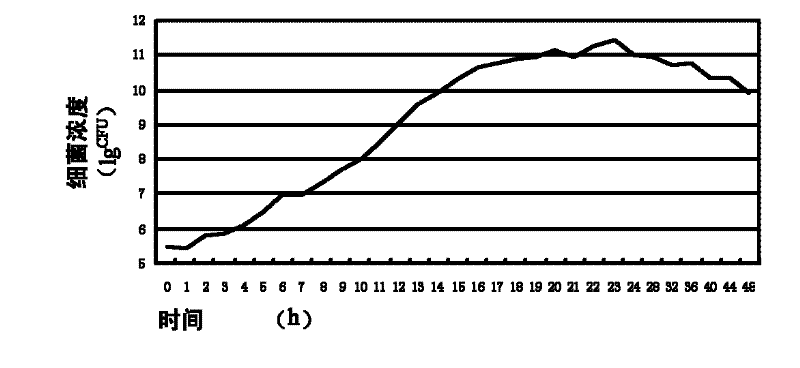

[0145] 1.1 Growth curve

[0146] MRS broth: peptone, 10g; Beef extract, 10g; Yeast extract powder, 5g; Dipotassium hydrogen phosphate, 2g; Diammonium citrate, 2g; Glucose, 20g; Magnesium sulfate heptahydrate, 0.58g; Manganese, 0.25g; Sodium acetate, 5g; Distilled water, 1000mL, 300mL MRS broth in a 500mL Erlenmeyer flask. Inoculate the culture of Lactobacillus fermentum according to 1% inoculation amount, take samples every 1h in the first 24h, and take samples at 28th, 32nd, 36th, 40th, 44th, 48h after 24h, take 1mL of culture solution and carry out gradient dilution, in 10 -2 ~10 -6 Dilution Take 0.3mL dilution and spread evenly on MRS agar (pH5.2), make 3 parallel samples for each gradient, place the plate at 37°C, 5% CO 2 In the incubator, cultivate for 24 hours, take the dilution of 50-150 colonies in the plate for calculation, make...

Embodiment 3

[0176] Example 3, the scavenging ability of Lactobacillus fermentum (Lactobacillus fermentum) HAFI5007 CGMCC No.4648 to free radicals

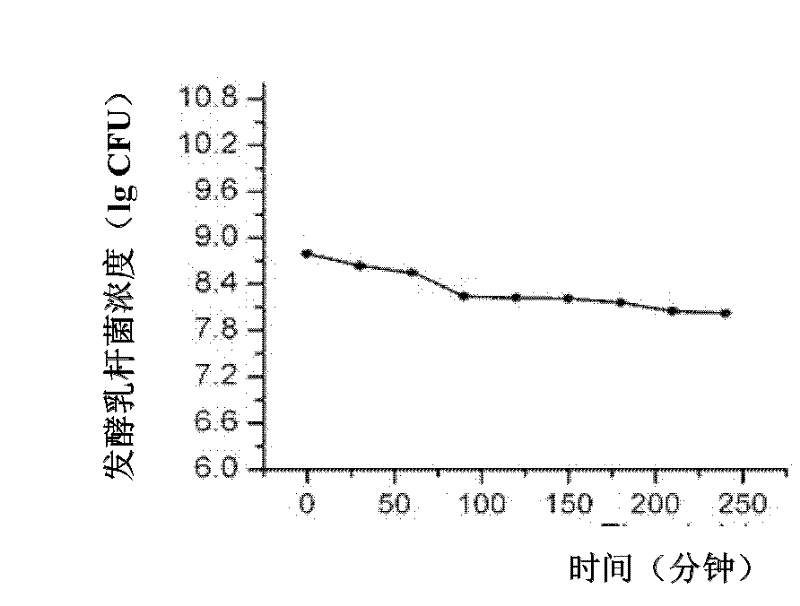

[0177] 1.1 Cultivation of Lactobacillus fermentum

[0178] MRS broth formula is the same as 1.1 in Example 2, adjust the pH to 5.4 with glacial acetic acid, mix it and put it into an anaerobic tube, each tube is equipped with 10mL broth, and fill it with 1.5% CO while it is hot 2 1min, seal, and autoclave. Lactobacillus fermentum (Lactobacillus fermentum) HAFI5007CGMCC No.4648 was inoculated in MRS at 1% after 24 hours of culture, and then cultured for 20 hours after inoculation. Centrifuge at 3,000rpm for 15min to collect the cells. Wash the centrifuged bacteria three times with sterilized normal saline, resuspend in normal saline, and adjust the number of bacteria to 10 6 、10 7 、10 8 and 10 9 CFU / mL.

[0179] 1.2 Determination of the tolerance of Lactobacillus fermentum to hydrogen peroxide

[0180] Refer to the method of Kullisaar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com