Environment-friendly type hyperconcentration biological enzyme liquid laundry detergent and preparation method thereof

A biological enzyme and laundry detergent technology, applied in the preparation of detergent mixture compositions, chemical instruments and methods, detergent compounding agents, etc., can solve the problems of poor water quality, eutrophication of rivers and lakes, poor detergency, etc. problems, to achieve the effect of easy preparation and mass production, elimination of liquid crystal and gel problems, and complete dispersion of solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

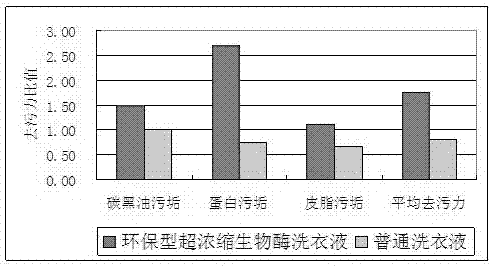

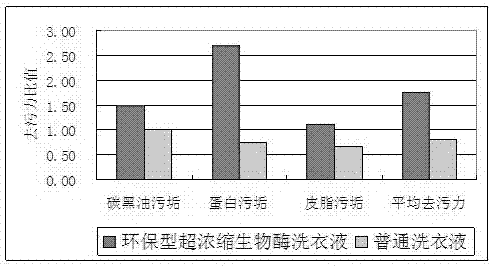

Image

Examples

Embodiment 1

[0045] Fatty alcohol polyoxyethylene ether sodium sulfate-70 type 20 kg, fatty alcohol polyoxyethylene ether-9 26 kg, secondary alkyl sulfonate sodium-60 type 15 kg, triethanolamine 8 kg, sodium citrate 3 kg, citric acid 0.2 kg, 1 kg myristic acid, 1 kg liquid protease, 0.5 kg liquid lipase, 0.5 kg borax, 5 kg propylene glycol, 12 kg dipropylene glycol butyl ether, 0.3 kg trichlorohydroxy diphenyl ether, 1,2-benzo 0.05 kg of isothiazolin-3-one, 0.2 kg of essence, and 7.25 kg of demineralized water. The raw materials are formulated into finished laundry detergent according to the above-mentioned preparation method.

Embodiment 2

[0047]Fatty alcohol polyoxyethylene ether sodium sulfate - 70 type 30 kg, fatty alcohol polyoxyethylene ether - 9 20 kg, secondary alkyl sulfonate - 60 type 6 kg, triethanolamine 5 kg, sodium citrate 2 kg, palmitic acid 0.6 kg, 0.5 kg of liquid protease, 0.2 kg of liquid lipase, 6 kg of propylene glycol, 2 kg of ethanol, 12 kg of dipropylene glycol propyl ether, 0.002 kg of methylisothiazolinone / chloromethylisothiazolinone, 0.2kg of essence, 15.498 kg of demineralized water. The raw materials are formulated into finished laundry detergent according to the above-mentioned preparation method.

Embodiment 3

[0049] Fatty alcohol polyoxyethylene ether sodium sulfate - 70 type 15 kg, fatty alcohol polyoxyethylene ether - 9 28 kg, secondary alkyl sulfonate - 60 type 15 kg, triethanolamine 8 kg, sodium citrate 2 kg, palmitic acid 1.6 kg, 1 kg liquid protease, 3 kg propylene glycol, 8 kg diethylene glycol butyl ether, 3 kg sodium xylene sulfonate, 0.3 kg triclosan, 1,2-benzisothiazoline-3- Ketone 0.05 kg, essence 0.2 kg, demineralized water 14.85 kg. The raw materials are formulated into finished laundry detergent according to the above-mentioned preparation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com