Star-shaped tetraarylethene compound and its preparation method and use

A technology of tetraarylethene and compound, applied in the field of organic light-emitting materials, can solve the problems of weak light absorption ability, difficult to meet device requirements, and low thermal stability of compounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

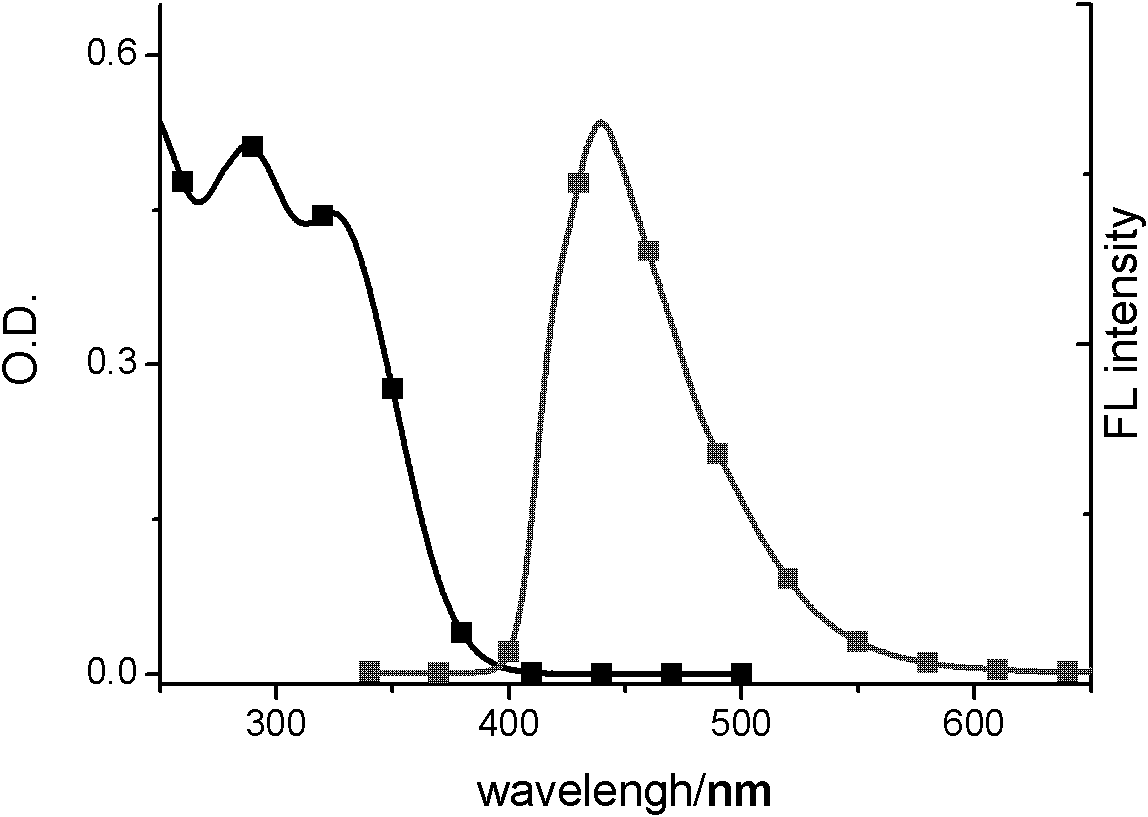

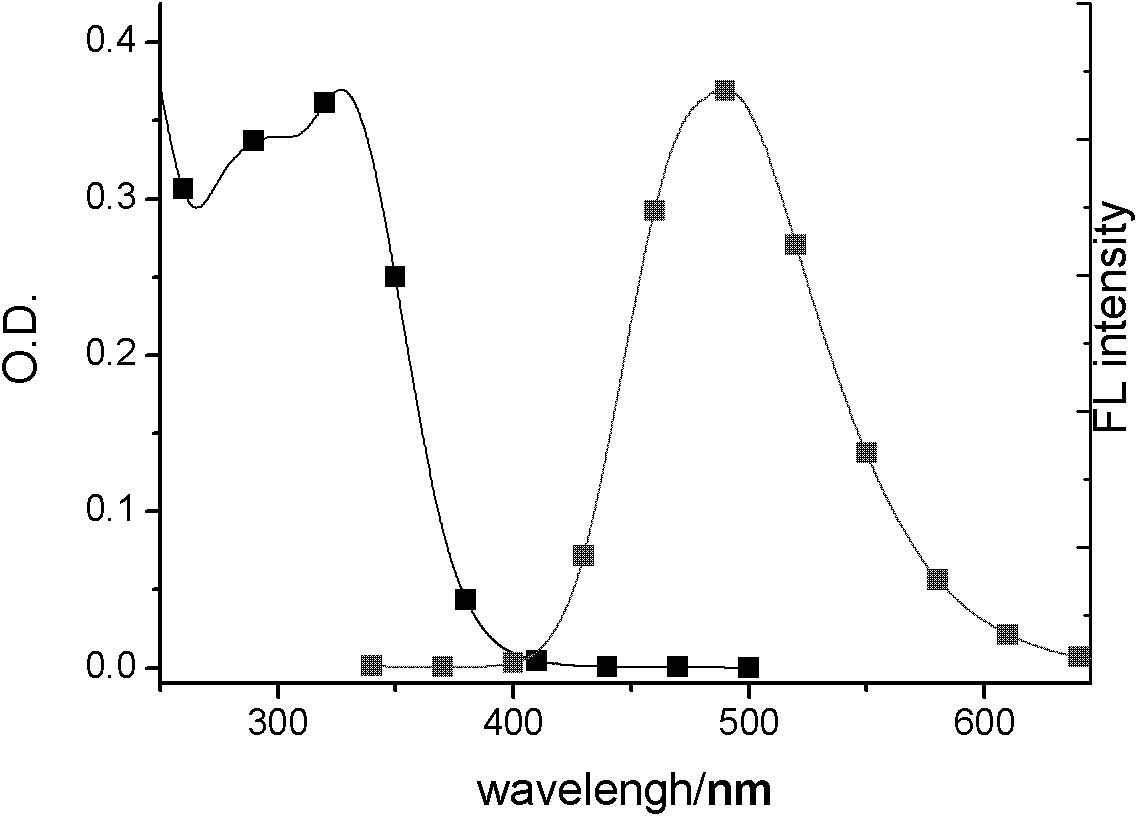

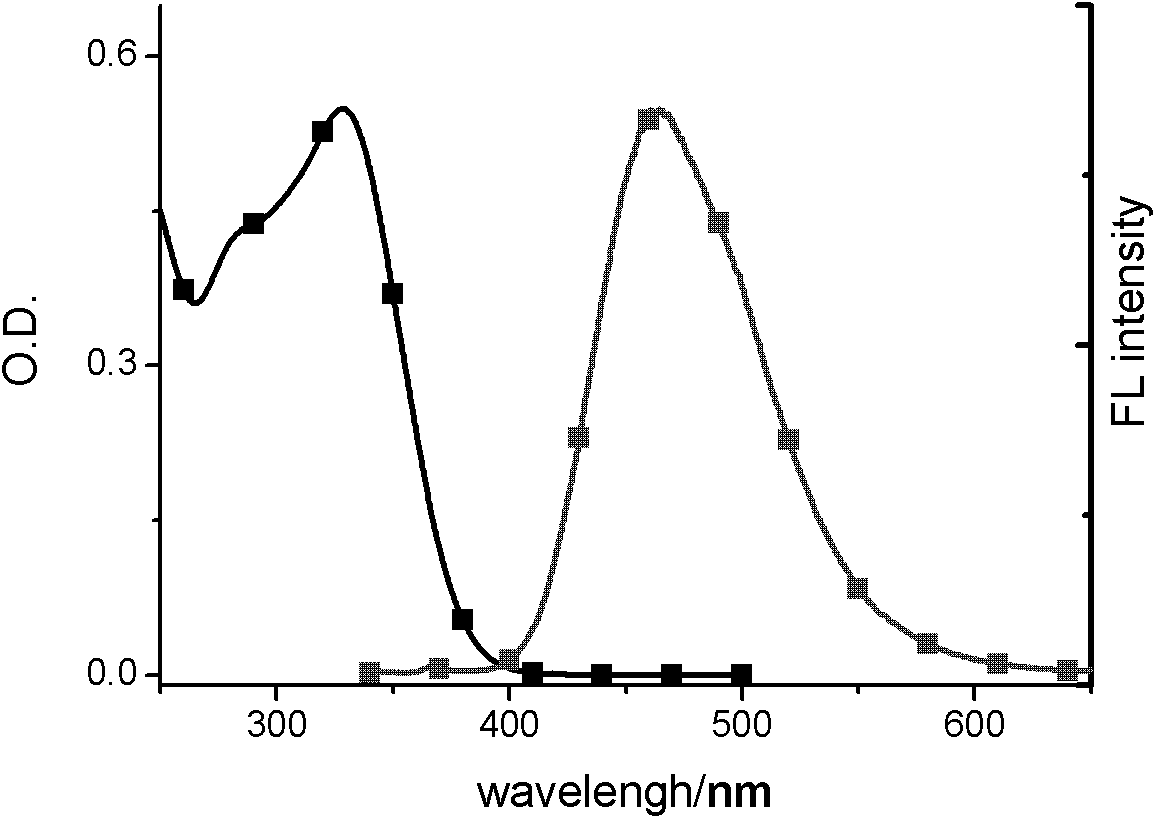

Image

Examples

Embodiment 1

[0053] Preparation of 1-(4-bromophenyl)-1,2,2-triphenylethylene (TPE-Br)

[0054]

[0055] Add 2.02g (12mmol) of diphenylmethane and 20mL of dry tetrahydrofuran into a 50mL Schlenk reaction flask, and place the system in a low-temperature bath at -78°C after removing water and oxygen, and add 4.55mL of 2.2M (10mmol) The butyllithium solution was slowly added dropwise to the system, kept at -78°C, and reacted for 2 hours. Then 2.18g (9mmol) of 4-bromodiphenyl ketone was dissolved in a small amount of dry tetrahydrofuran, and this solution was injected into the reaction system (maintained at -78°C), and then the reaction system was slowly raised to room temperature for 12 hours of reaction. After the reaction, pour the reaction solution into water to terminate the reaction, extract the reaction solution three times with dichloromethane, combine the organic phases, wash with saturated ammonium chloride, saturated saline, water three times, and anhydrous Na 2 SO 4 Dry and spi...

Embodiment 2

[0058] Preparation of 4-(1,2,2-triphenylethenyl)phenylboronic acid (TPE-B(OH) 2 )

[0059]

[0060] Add 1.67g (4.0mmol) TPE-Br into a 100mL Schlenk reaction flask, repeat vacuuming-nitrogen three times, and add 40mL THF under nitrogen atmosphere. The reaction flask was placed in a low-temperature bath (-78°C), and 3.2mL of 2.5M (0.8mmol) n-butyllithium was carefully added dropwise with a syringe, and the reaction was stirred at -78°C for 3h. Then 2.4 mL (22.1 mmol) of trimethyl borate in THF were added at -78°C. The reaction system was raised to room temperature and stirred for 12 h, and the reaction was terminated with 10 mL of 2M HCl. The reaction solution was poured into water, with CH 2 Cl 2 The aqueous phase was extracted several times, and the organic phases were combined, washed with saturated brine and water three times respectively, and anhydrous Na 2 SO 4 After drying, the solvent was spin-dried and separated by a chromatographic column (200-300 mesh silica ...

Embodiment 3

[0062] Preparation of 1,2-bis(4'-(1,2,2-triphenylethenyl)-[1,1'-biphenyl]-4-yl)acetylene

[0063]

[0064] Add 376mg (1.0mmol) TPE-B(OH) to a 150mL Schlenk reaction flask 2 , 134mg (0.4mmol) bis(4-bromophenyl) acetylene and 20mg (0.017mmol) tetrakistriphenylphosphine palladium, repeat vacuuming-nitrogen operation three times, add 50mL THF and 3mL 2M sodium carbonate under nitrogen atmosphere aqueous solution, stirred and refluxed overnight. The reaction solution was poured into water, the aqueous phase was extracted several times with dichloromethane, the organic phases were combined, washed with saturated saline and water three times respectively, and washed with anhydrous Na 2 SO 4 Dry, spin to dry the solvent, and use petroleum ether / dichloromethane as the eluent to separate on a chromatographic column (200-300 mesh silica gel) to obtain 250 mg of a white solid with a yield of 74.5%. 1 HNMR (400MHz, CDCl 3 ), d (ppm): 7.89 (d, 2H, J=8.0Hz), 7.13-7.01 (m, 17H), 4.49 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com