Mixed-phase nitride film field emission cathode with enhanced electron emission and preparation method thereof

A Field Emission Cathode, Electron Emission Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

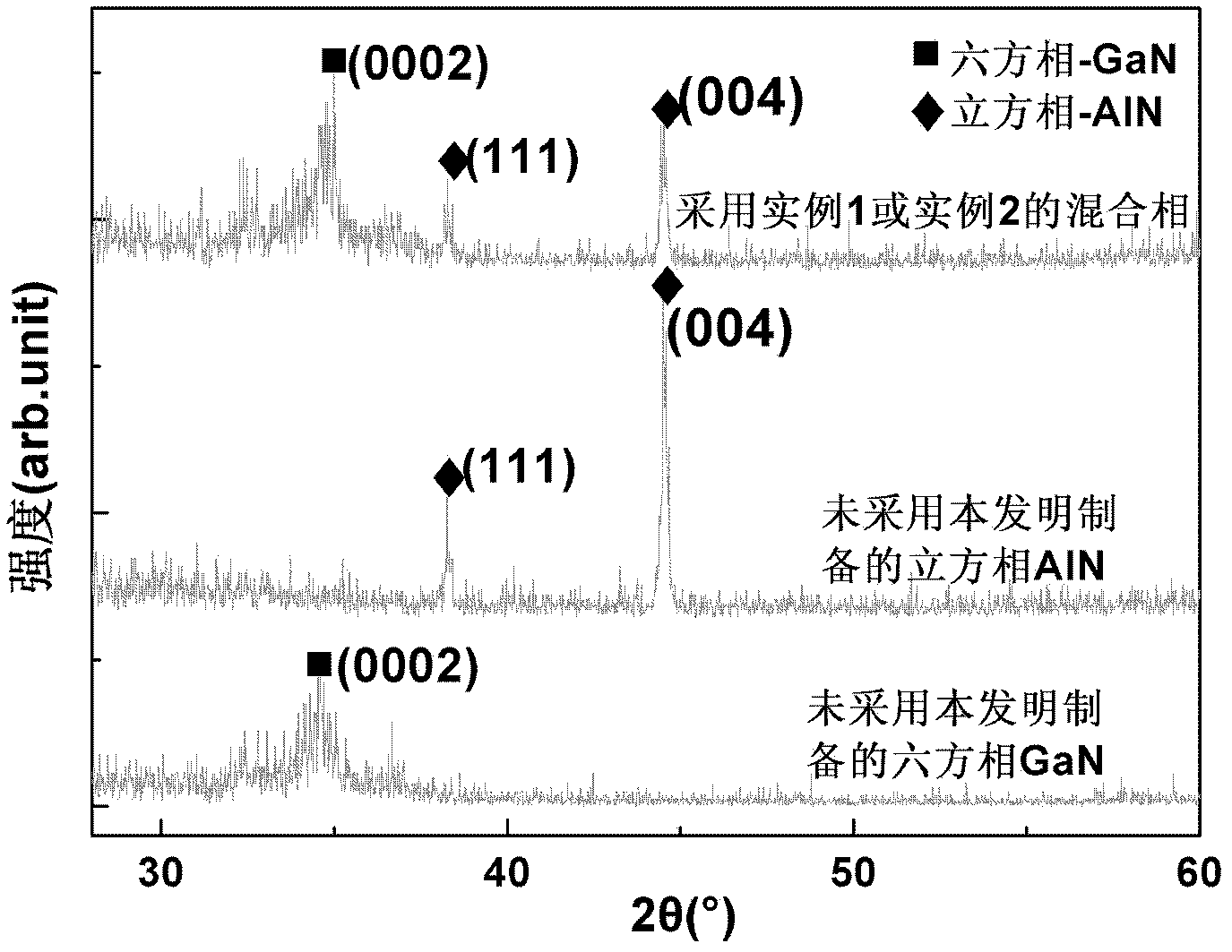

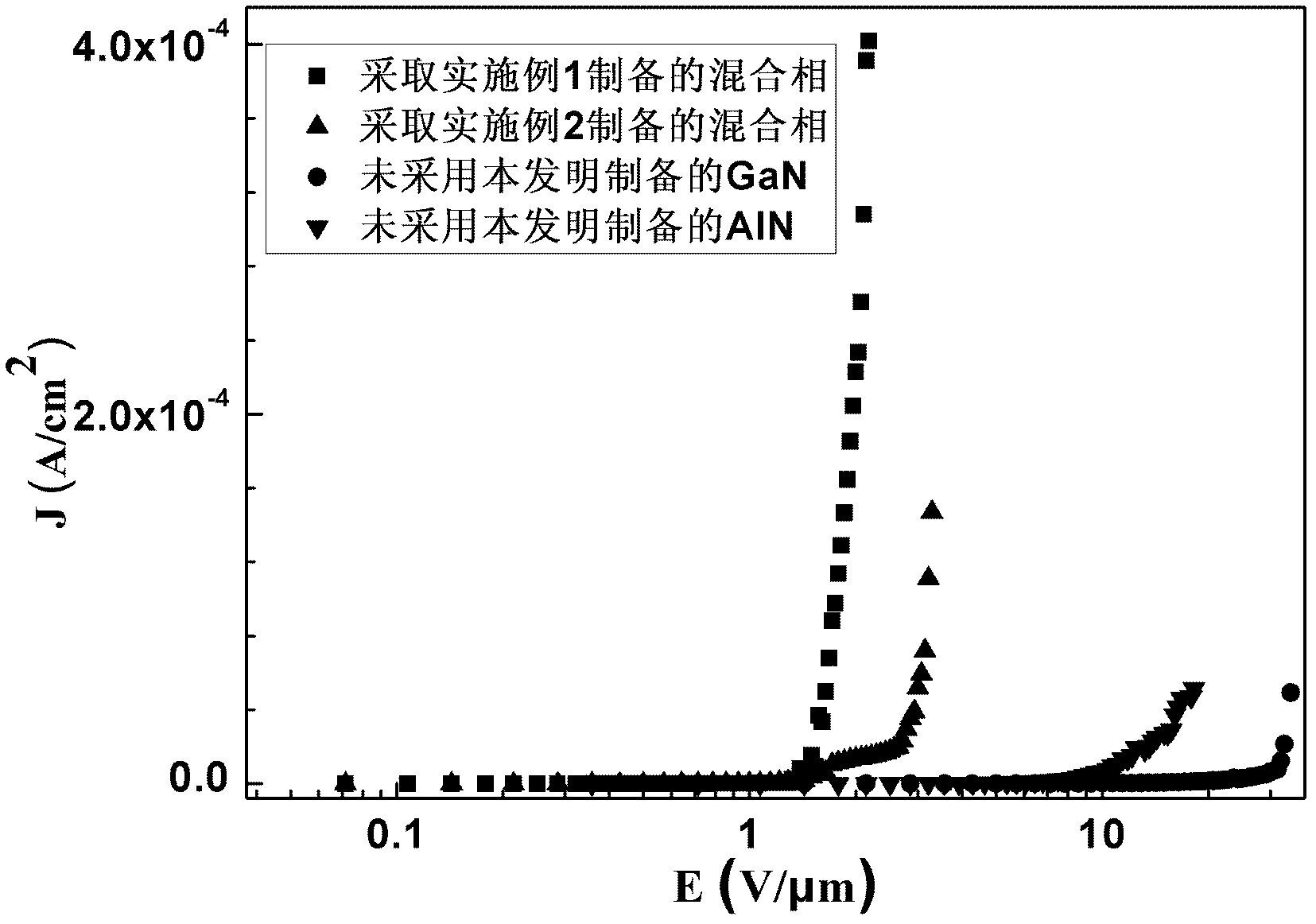

[0025] The target material in this embodiment is uniformly mixed powder of AlN and GaN (purity>98%, molar ratio 1:1) which is sintered into a target. Use polished n-type (100) doped silicon as the substrate, soak the substrate in 5% HF acid for 3 minutes, then clean it with deionized water, dry the surface of the substrate, and put the substrate into the laser pulse deposition system chamber, pump the deposition chamber to approximately 7 x 10 -4 Pa, and heat the substrate to 900°C. The growth conditions are: supply nitrogen with a purity of 99.99% as a protective gas and adjust the working pressure of the deposition chamber to 1Pa, the distance between the target and the base to 80mm, set the frequency of the pulsed laser to 13Hz, the pulse energy to 350mJ / pulse, and the deposition time to be 300s , deposit a 150nm thick layer of unintentionally doped n-type Al 0.5 Ga 0.5 The N thin film was annealed in situ for 30 min, and finally dropped to room temperature under the pro...

Embodiment 2

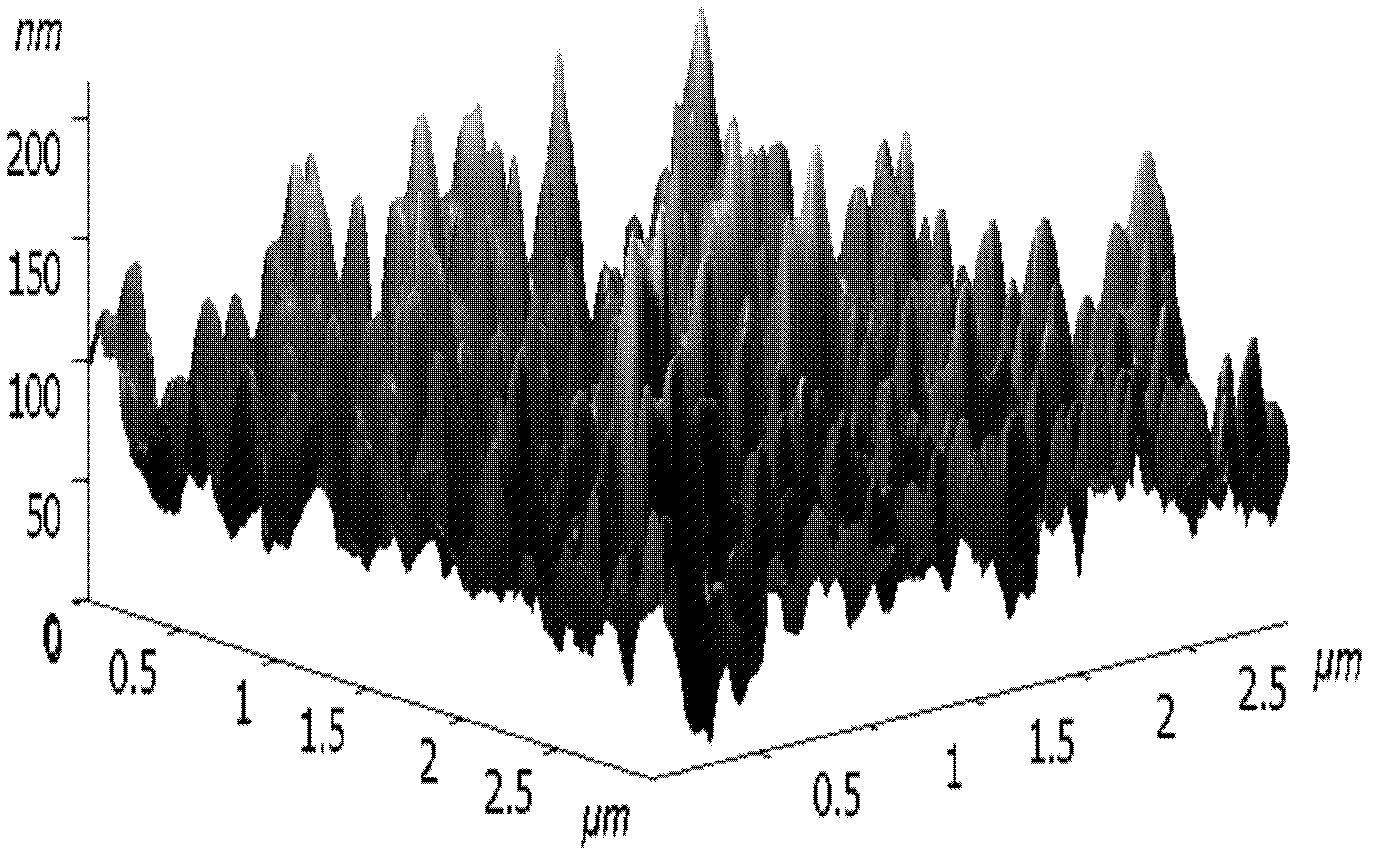

[0027] The target material in this embodiment is uniformly mixed powder of AlN and GaN (purity>98%, molar ratio 1:1) which is sintered into a target. Use polished n-type (111) doped silicon as the substrate, soak the substrate in 7% HF acid for 3 minutes, then clean it with deionized water, dry the surface of the substrate, and put the substrate into the laser pulse deposition system chamber, pump the deposition chamber to approximately 7 x 10 -4 Pa, and heat the substrate to 850°C. The growth conditions are as follows: supply nitrogen with a purity of 99.99% as a protective gas and adjust the working pressure of the deposition chamber to 1Pa, the target base distance to 60mm, set the pulse laser frequency to 13Hz, pulse energy to 375mJ / pulse, and deposit a layer of 280nm Thick unintentionally doped n-type Al 0.5 Ga 0.5 The N thin film was annealed in situ for 30 min, and finally dropped to room temperature under the protection of nitrogen. The nano-film has a surface root...

Embodiment 3

[0029] The target material in this embodiment is uniformly mixed powder of AlN and GaN (purity>98%, molar ratio 1:1) which is sintered into a target. Use polished Al as the substrate, put the substrate into the cavity of the laser pulse deposition system, and pump the deposition chamber to about 2×10 -3 Pa, and heat the substrate to 650°C. The growth conditions are as follows: supply nitrogen with a purity of 99.99% as a protective gas and adjust the working pressure of the deposition chamber to 5Pa, the target base distance to 60mm, set the pulse laser frequency to 13Hz, pulse energy to 400mJ / pulse, and deposit a layer of 150nm Thick unintentionally doped n-type Al 0.5 Ga 0.5 The N thin film was annealed in situ for 30 min, and finally dropped to room temperature under the protection of nitrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com