A kind of synthetic method of mesoporous silica-alumina molecular sieve

A technology of mesoporous silica-alumina and synthesis methods, applied in molecular sieve compounds, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve problems such as narrow pore size distribution, achieve concentrated pore size distribution, large pore volume, and avoid mass use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mesoporous silica-alumina molecular sieves were prepared using tetraethyl orthosilicate as silicon source, aluminum nitrate as aluminum source and sucrose as template.

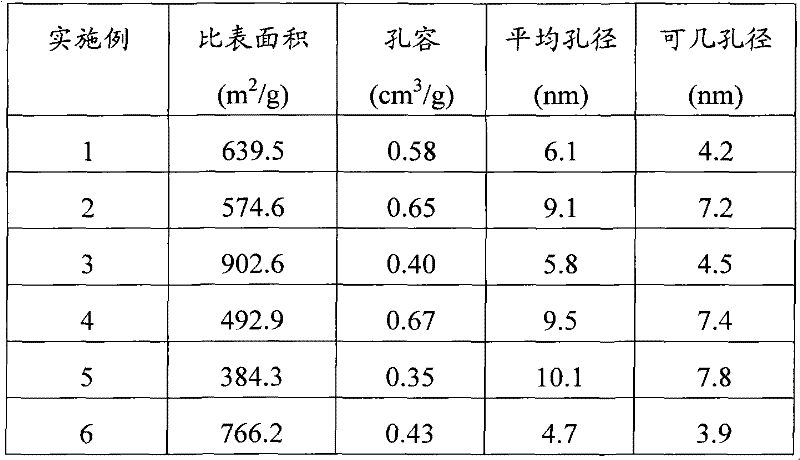

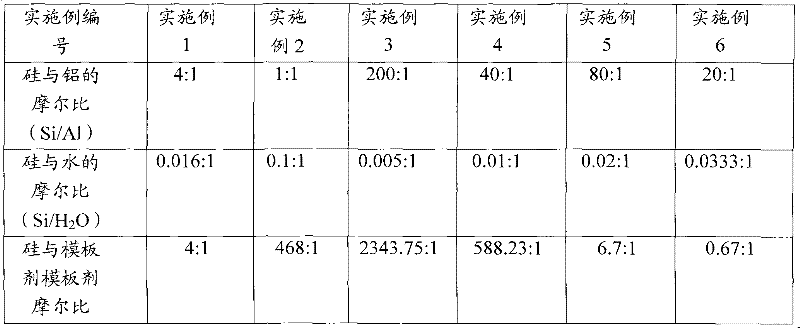

[0026] With 8.59g ethyl orthosilicate (Beijing Chemical Reagent Company, analytically pure), 3.79g aluminum nitrate (Al(NO 3 ) 3 9H 2 O, Shanghai Zhenxin Reagent Factory, mass content 99.0%), 3.96g sucrose (Sinopharm Chemical Reagent Co., Ltd., analytically pure) was added in 45ml water (deionized water, the same below), at room temperature (26 ° C, the same below) , stirred for 2 hours, adjusted the pH value to 5.0 with a dilute hydrochloric acid solution with a concentration of 10% by weight, stirred for another 5 hours, and then stood and aged at 40 ° C for 96 hours, filtered the resulting mixture, and washed with deionized water , dried at 150°C for 8 hours, and then calcined at 500°C for 12 hours to obtain a mesoporous silica-alumina molecular sieve. The physical and chemical properties of the ob...

Embodiment 2

[0028] Mesoporous silica-alumina molecular sieves were prepared using methyl orthosilicate as silicon source, aluminum isopropoxide as aluminum source and dextran as template.

[0029] 6.15g methyl orthosilicate (Beijing Chemical Reagent Company, analytically pure), 8.21g aluminum isopropoxide (Sinopharm Chemical Reagent Co., Ltd., Al mass content 24.7%), 6.84g dextran (Sinopharm Chemical Reagent Co., Ltd. Company, analytically pure, molecular weight is 80,000) join in 72ml water, stir 4 hours at room temperature, add concentration and be 10% by weight dilute nitric acid solution and adjust pH value to be 4.0, stir 6 hours, leave standstill aging at 60 ℃ then for 72 hour, filtered, washed with deionized water, then dried at 120°C for 15 hours, and calcined at 600°C for 9 hours to obtain a mesoporous silica-alumina molecular sieve. The physical and chemical properties of the obtained products are shown in Table 1. The feeding ratio is shown in Table 2.

Embodiment 3

[0031] Mesoporous silica-alumina molecular sieves were prepared using sodium silicate as silicon source, aluminum isopropoxide as aluminum source and starch as template.

[0032] 28.7g sodium silicate (Na 2 SiO 3 9H 2O, Sinopharm Chemical Reagent Co., Ltd., analytically pure), 1.03g aluminum isopropoxide (Sinopharm Chemical Reagent Co., Ltd., Al mass content 24.7%), 12.8g starch (Sinopharm Chemical Reagent Co., Ltd., analytically pure, average molecular weight 300,000) into 360ml of water, stirred at room temperature for 3 hours, adjusted the pH value to 10.0 with a concentration of 10% dilute sulfuric acid solution by weight, stirred for another 6 hours, then left to age at 80°C for 48 hours, filtered, filtered The cake was washed with deionized water, dried at 110°C for 24 hours, and calcined at 650°C for 6 hours to obtain a mesoporous silica-alumina molecular sieve. The physical and chemical properties of the obtained products are shown in Table 1. The feeding ratio is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com