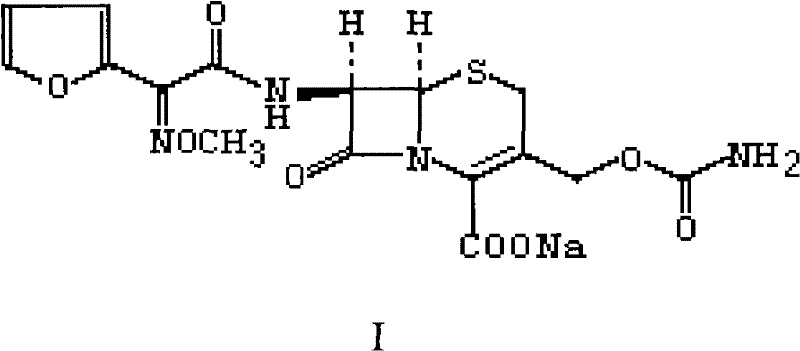

One-step recovery and preparation method of cefuroxime sodium

A technology of cefuroxime sodium and cefuroxime acid, which is applied in the field of medicine, can solve the problems of unsuitable storage, prolonged dissolution time, and long time, and achieve the effects of improving recovery work efficiency, good protection, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 10 grams of unqualified cefuroxime sodium (color and luster is equal to yellow No. 7, content 92%) in 100ml 95% ethanol and 200ml acetone, add hydrochloric acid 1.3ml (form by adding 0.65ml of water 0.65ml of 36% hydrochloric acid), Incubate at 10-15°C for 2 hours, cefuroxime sodium is gradually converted into cefuroxime acid and dissolved in the reaction system; add 1 g of activated carbon, stir for 15 minutes to decolorize, filter, filter out the activated carbon, and use 20ml of ethanol for the filter cake Wash, and combine the filtrate and the carbon washing solution to obtain a cefuroxime acid solution.

[0031] 20~25 ℃, add the mixed solution of 6 grams of 60% sodium lactate and 75ml ethanol into the above-mentioned cefuroxime acid solution under stirring, after adding, continue to stir for 1 hour, filter, collect and wash the crystals with ethanol, the crystals are at 35 Vacuum drying at ~45°C gave 9.2 g of cefuroxime sodium with a yield of 92%. The obtained...

Embodiment 2

[0033]Add 10 grams of unqualified cefuroxime sodium (color equal to yellow No. 8, content 91%) into 300ml of methanol and 150ml of acetone, add 10ml of sulfuric acid (prepared from 1ml of 98% sulfuric acid and 9ml of water), 0-10 ℃ for 1 hour, cefuroxime sodium is gradually converted into cefuroxime acid and dissolved in the reaction system, 2 grams of activated carbon is added, stirred for 15 minutes, filtered, washed with 50ml of methanol, and the filtrate and carbon washing liquid are combined to obtain cephalosporin Furoic acid solution.

[0034] 0~15℃, add the mixed solution of 12.5 grams of 60% sodium lactate and 120ml of acetone into the above cefuroxime acid solution under stirring, after the addition, continue to stir for 4~5 hours, filter, collect and wash the crystals with acetone, the crystals are in Vacuum drying at 35-45°C gave 8.9 g of cefuroxime sodium with a yield of 89%. The color of the obtained cefuroxime sodium was detected according to the detection meth...

Embodiment 3

[0036] Add 10 grams of unqualified cefuroxime sodium (the clarity of cefuroxime sodium is greater than No. 2 turbidity standard solution, content 91%) in 80ml acetone and 20ml isopropanol, add hydrochloric acid 2.2ml (by 36% hydrochloric acid 1.1 ml and 1.1ml of water), and react at 40-50°C for 0.5 hours, cefuroxime sodium is gradually converted into cefuroxime acid and dissolved in the reaction system, add 0.1 g of activated carbon, stir for 15 minutes, filter, and use 20ml Wash with acetone, and combine the filtrate and the carbon washing liquid to obtain a cefuroxime acid solution.

[0037] 40~50℃, add 8 grams of sodium isooctanoate, 16ml of acetone and 1.6ml of water into the above cefuroxime acid solution under stirring, after the addition, continue to stir for 1 hour, filter, collect and wash the crystals with acetone, the crystals Vacuum drying at 35 to 45°C yielded 8.7 grams of cefuroxime sodium, with a yield of 87%, and the obtained cefuroxime sodium was detected by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com