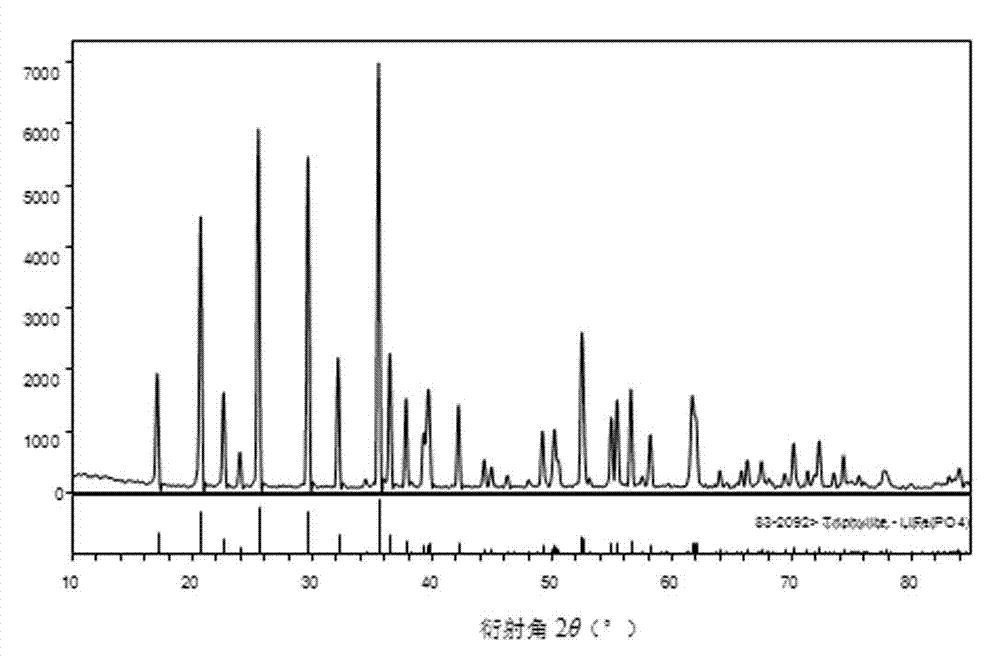

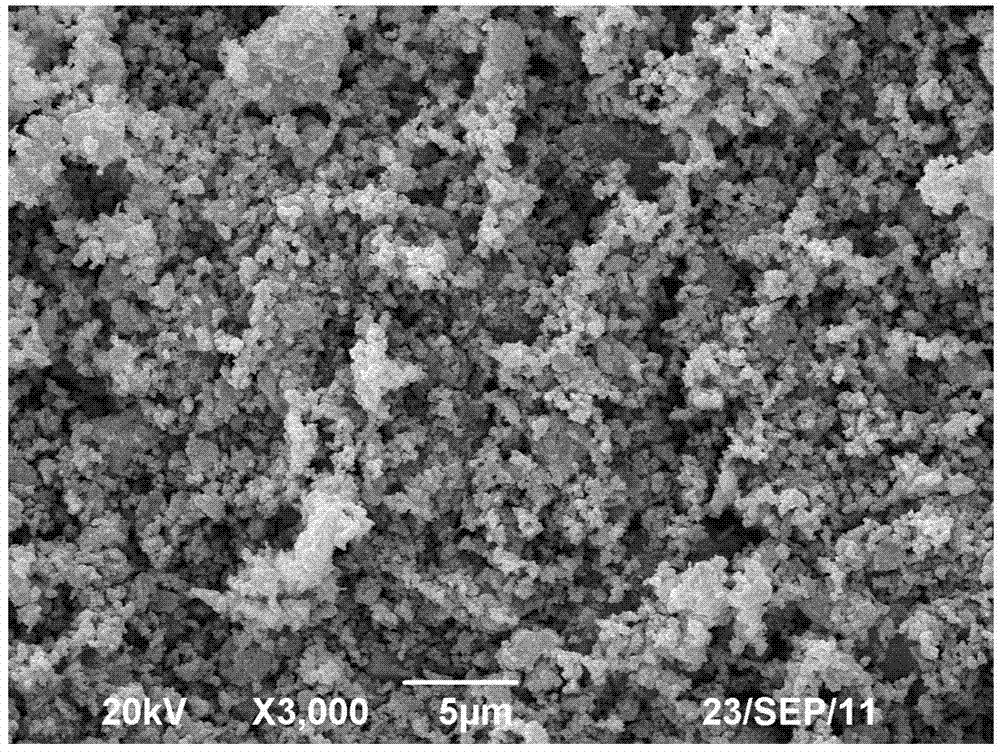

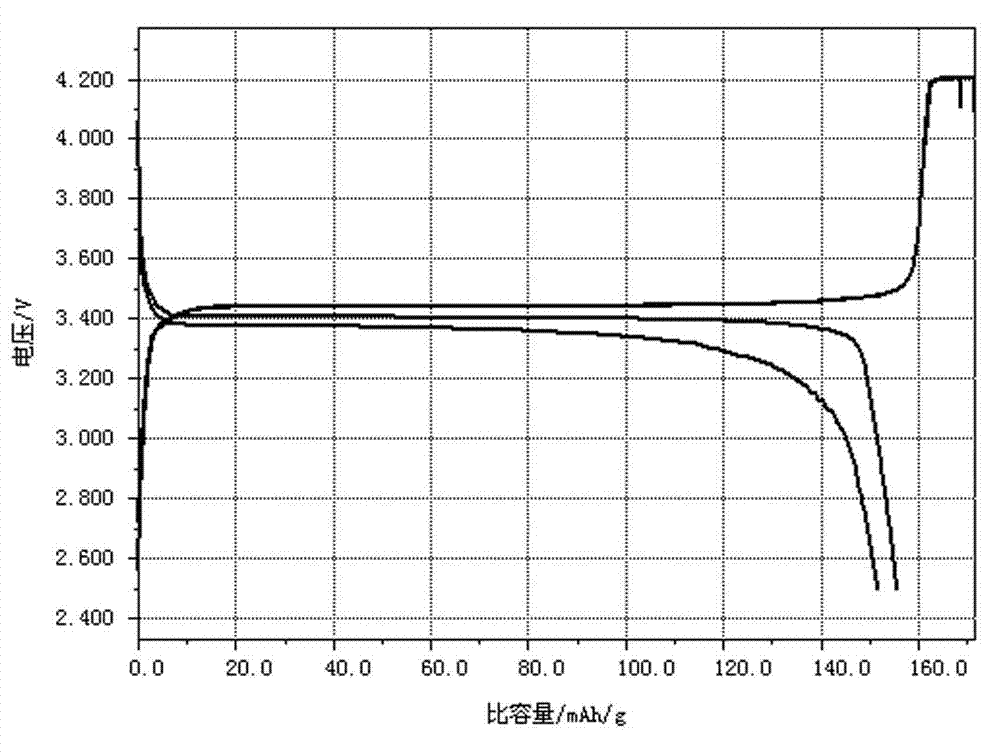

Method for synthesizing lithium iron phosphate by ultrasonic spray solid-phase sintering

A technology of lithium ferrous phosphate and solid phase sintering method, which is applied to chemical instruments and methods, phosphorus compounds, structural parts, etc., to achieve the effects of improving processing performance and electrochemical performance, uniform particle size distribution, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 166.85 g of ferrous sulfate heptahydrate and 52.810 g of diammonium hydrogen phosphate, respectively dissolve them in 1.0 L of deionized water, stir to dissolve them; mix ferrous sulfate solution and diammonium hydrogen phosphate solution At the same time, add it into a reactor with an ultrasonic device at a rate of 800 mL / h, control the reaction temperature at 80 °C, and react for 1 h at a stirring speed of 800 r / min to obtain a gray-white ferrous phosphate suspension; Then add 20.80g of lithium dihydrogen phosphate, 14.80g of lithium carbonate, 6.04g of glucose, 90.05g of oxalic acid, 0.2g of titanium oxide and 0.2g of manganese acetate tetrahydrate, and spray-dry during intensive stirring and mixing, with a feed rate of 800 mL / h, the dry air inlet temperature is 220°C, and the air outlet temperature is 120°C to obtain the lithium iron phosphate precursor, and then pretreat at 300°C for 4h under the protection of a high-purity nitrogen atmosphere; take 90g o...

Embodiment 2

[0027] (2) Weigh 172.82 g of ferrous nitrate hexahydrate and 59.60 g of ammonium phosphate, respectively dissolve them in 12.0L of deionized water, and add ferrous nitrate solution and ammonium phosphate solution at the same time at a rate of 1000 mL / h Into a reactor equipped with an ultrasonic device, control the reaction temperature to 50 °C, and react for 0.5 h under the condition of a stirring speed of 400 r / min to obtain a suspension close to white ferrous phosphate; then add 23.20 g of lithium phosphate, 6.28 g sucrose, 15.0 g acetylene black, 5.0 g acetic acid, 0.3 g niobium oxide and 0.1 g cobalt acetate tetrahydrate were spray-dried in the process of intensive stirring and mixing, and the feed rate was 1200 mL / h, and the drying inlet air temperature was 150°C, the air outlet temperature is 100°C, to obtain the complex precursor of lithium iron phosphate containing composite carbon sources and composite metal elements, and then pretreat at 200°C for 2 hours under the pr...

Embodiment 3

[0030] (3) Weigh 104.40 g of ferrous acetate and 46.0 g of ammonium dihydrogen phosphate, and dissolve them in 0.3 L of deionized water respectively. Speed into the reactor with an ultrasonic device, control the reaction temperature at 90 °C, and react for 8 h under the condition of a stirring speed of 1200 r / min to obtain a suspension of gray ferrous phosphate; then add 23.00 g of dihydrogen phosphate Ammonium, 30.60 g lithium oxalate, 10.0 g malic acid, 10.0 g graphite, 10.0 g phenolic resin, 0.2 g magnesium oxide, and 0.2 g aluminum oxide; spray-dried during intensive mixing with a feed rate of 400 mL / h , the dry air inlet temperature is 250°C, and the air outlet temperature is 150°C to obtain the precursor of lithium iron phosphate, and then pretreat at 400°C for 8 hours under the protection of a high-purity nitrogen atmosphere; take 90g of pretreated ferrous phosphate Lithium sample, add 25.0g malic acid and 35.0g phenolic resin to the sample, through high-speed mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com