Three-dimensional network-like chitosan-calcium carbonate nano composite material as well as preparation method and cell compatibility thereof

A composite material, chitosan technology, applied in the application field of the composite material in cell culture, can solve the problem of low mechanical properties of the composite material, and achieve the effect of good material cell-interface, good mechanical strength, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

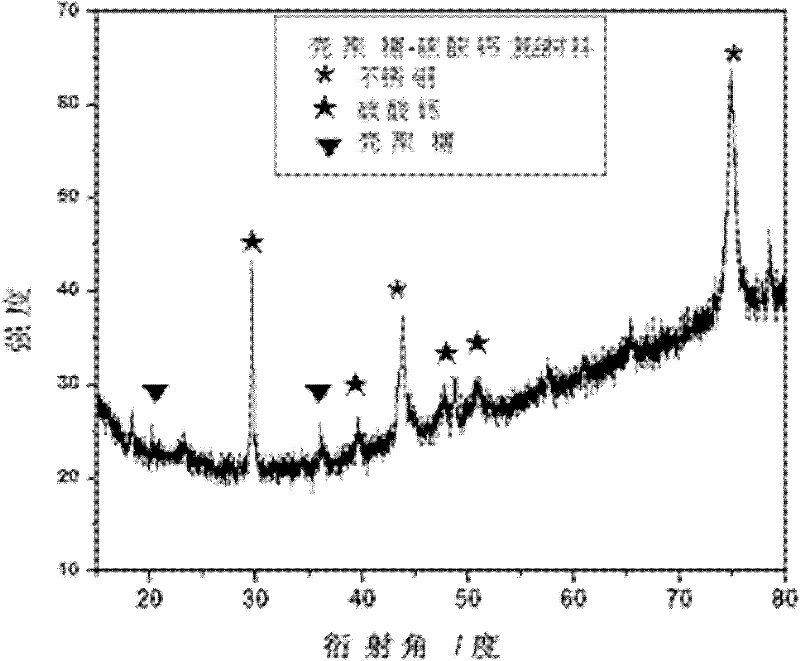

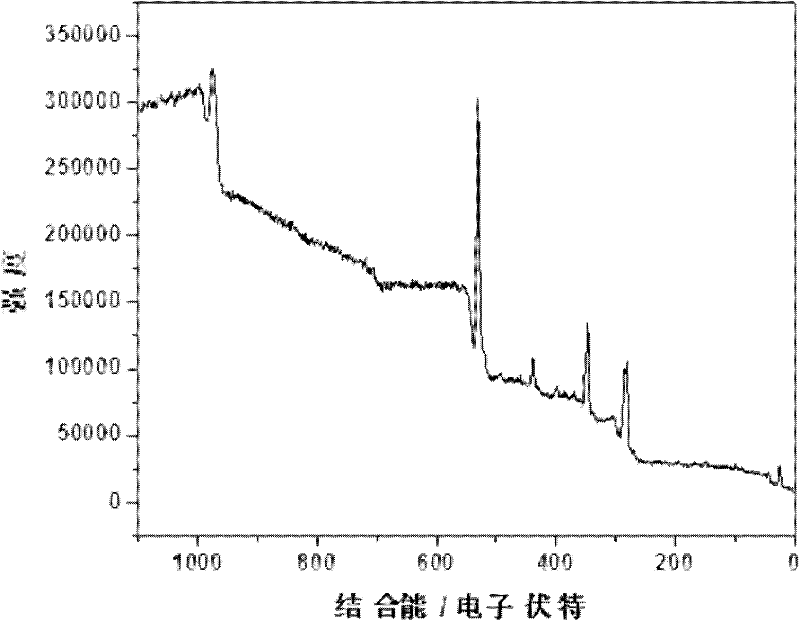

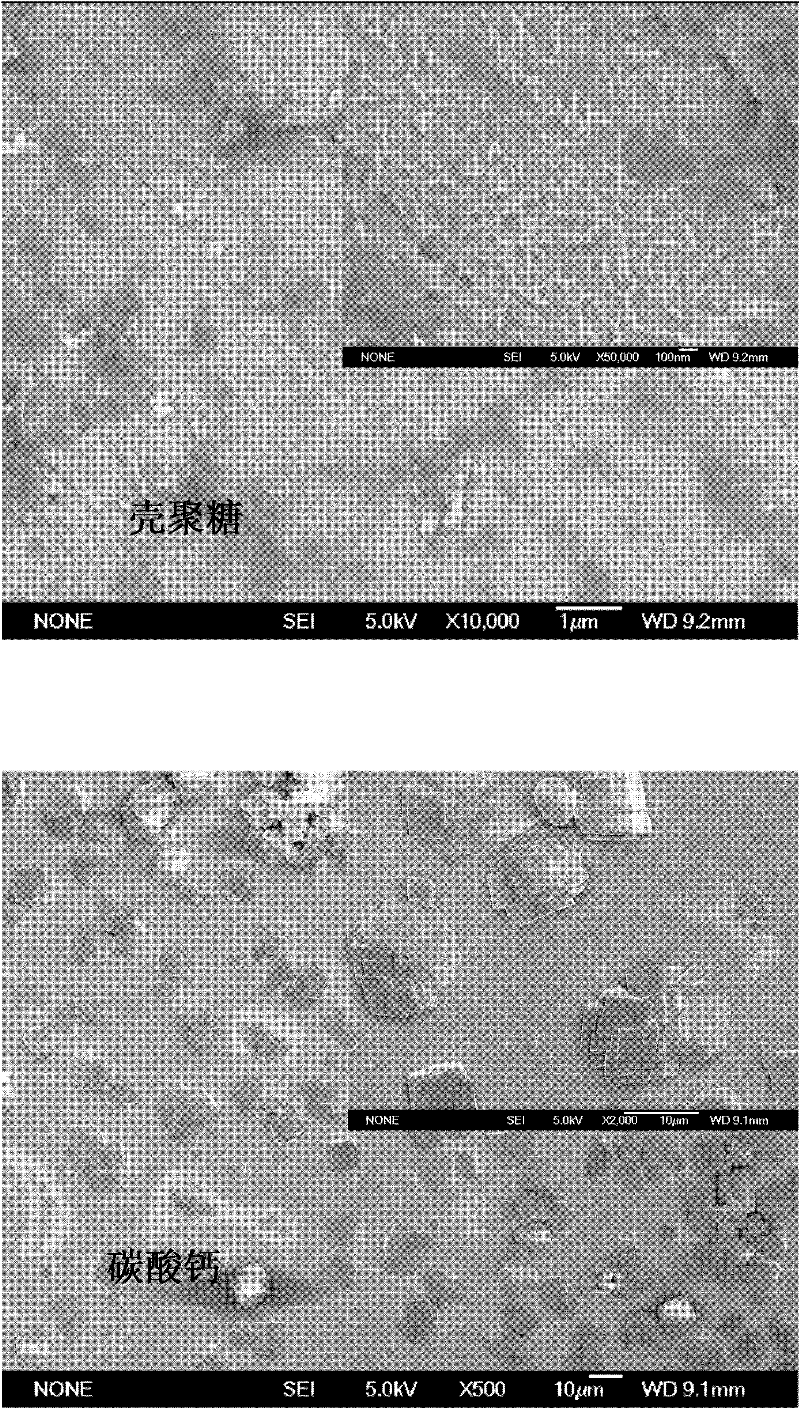

[0040] Preparation of chitosan-calcium carbonate fiber network composites

[0041] According to chitosan and calcium carbonate mass ratio is 5~5.5: 1 batching, the present embodiment takes the upper, middle and lower three points of this ratio range as representative experiment, and its chitosan and calcium carbonate mass ratio are 5.00: 1 , 5.25:1, 5.50:1, the preparation steps are as follows:

[0042] 1) Dissolve 0.8190g, 0.8600g, and 0.9010g chitosan in 200ml deionized water, adjust the pH to 5.0 with 2M HCl solution, stir overnight with magnetic force, and then adjust the pH to 5.0;

[0043] 2), take 50ml of the above-mentioned three different concentrations of solutions, first add 0.0660g of calcium chloride dihydrate, the final concentration is 9mM, stir magnetically, then add 0.0711g of ammonium bicarbonate, the final concentration is 18mM, continue to stir, and then Adjust the pH of the solution to 5.5;

[0044] 3), open the CHI-660 workstation online, use the above ...

Embodiment 2

[0051] The chitosan-calcium carbonate composite material cytocompatibility experiment prepared in embodiment 1

[0052] (Take chitosan and the composite material that calcium carbonate mass ratio is 5.25: 1 for experiment)

[0053] The preparation steps are as follows:

[0054] 1), the bare stainless steel sheet and the chitosan-calcium carbonate composite material prepared as a base with the stainless steel sheet are cut into a square with a side length of 0.8 cm.

[0055] 2) Sterilize both sides of the cut sample with alcohol and ultraviolet light, then place it in a 24-well culture plate, digest the overgrown cells in the culture bottle, and dilute to a density of 1×10 4 / ml pieces. The cells were seeded in a 24-well culture plate, and 200ul of cells and 800ul of medium were added to each well. At 37°C, 5% CO 2 Cultivate in an incubator (3 control wells are set for each group of samples when measuring fluorescence, and 6 control wells are set for each group of samples w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com