Growing-finishing pig later-stage microorganism fermentation antibiotics-free feed

A microbial fermentation, growth and fattening technology, applied in animal feed, animal feed, additional food elements, etc., to achieve good synergy, improve immunity, improve the economic benefits of breeding and the quality of pork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

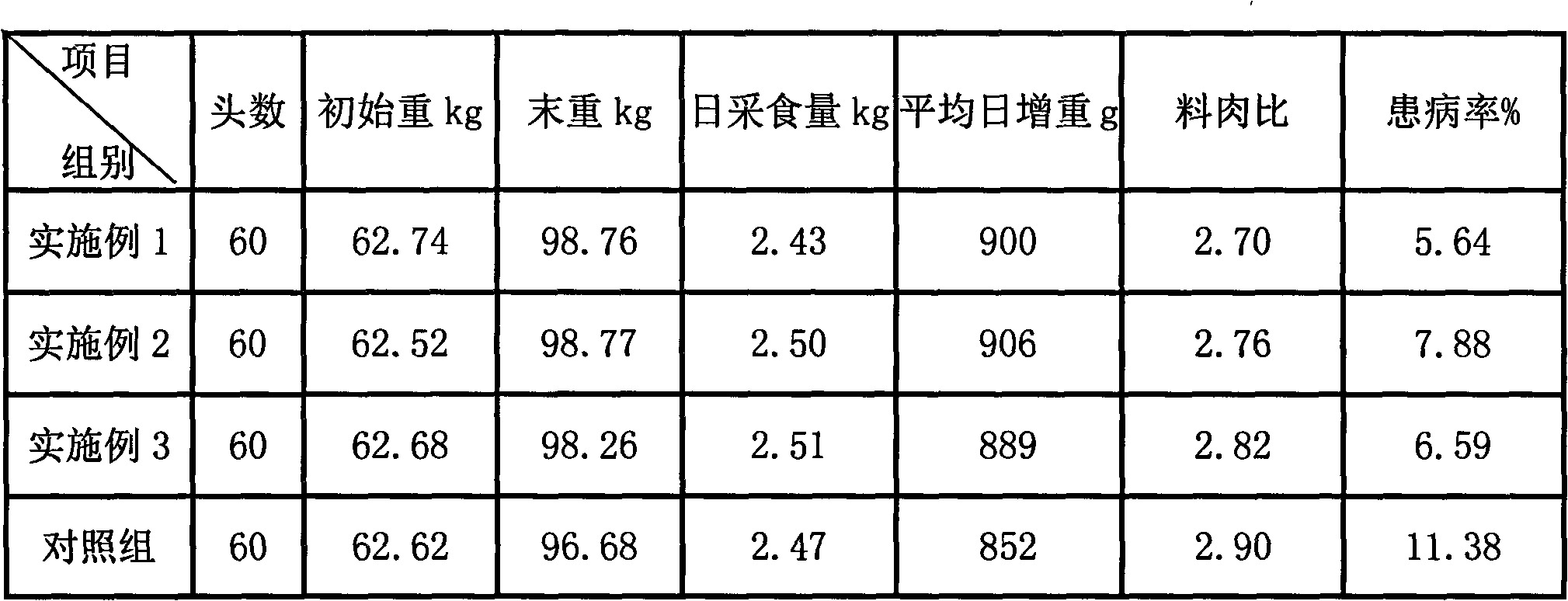

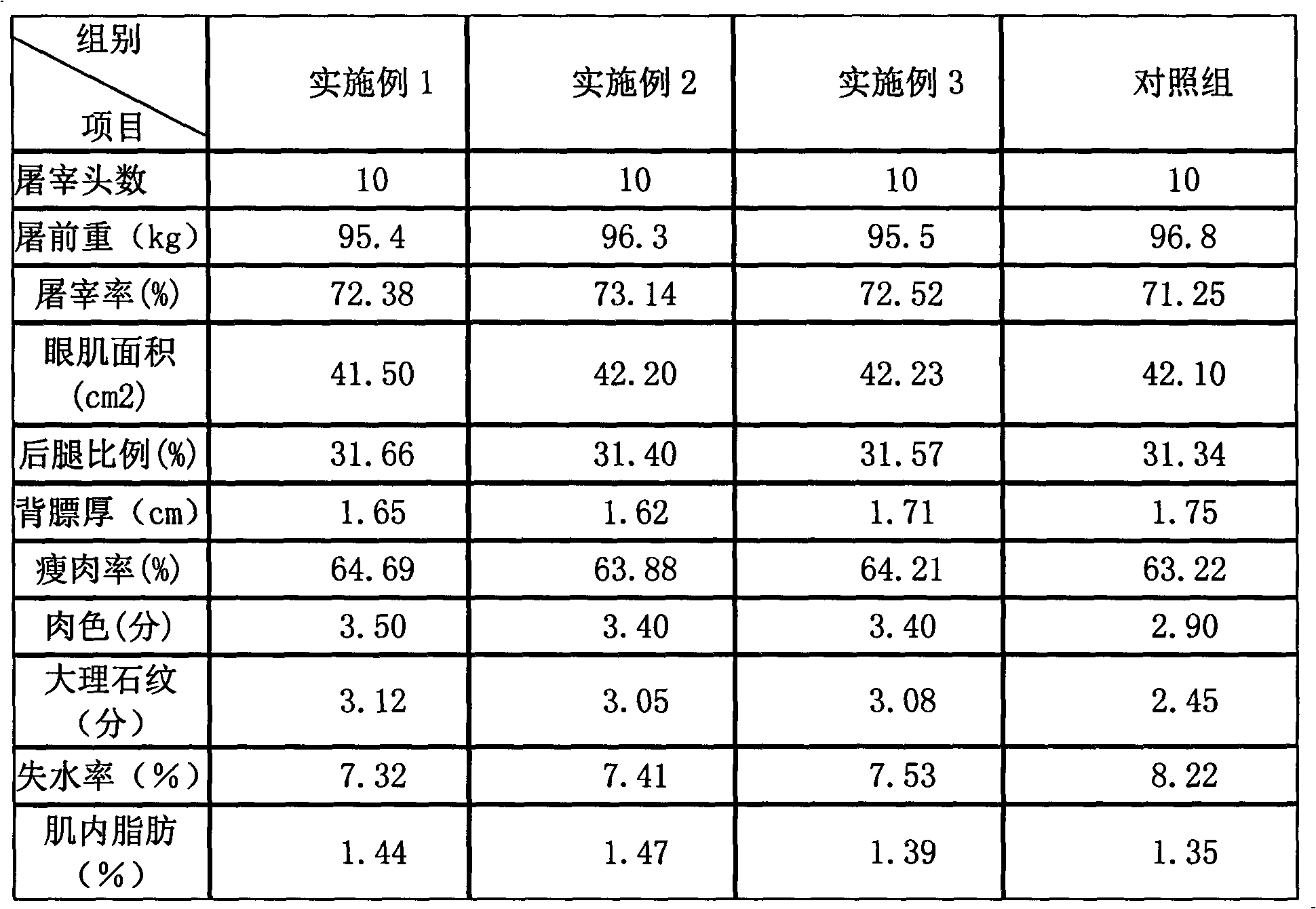

Examples

Embodiment 1

[0016] The late-stage microbial fermentation antibiotic-free feed for growing and finishing pigs is made by mixing batch materials and compound fermentation materials, wherein the weight ratio of batch materials to compound fermentation materials is: 95:5.

[0017] The batching material is prepared from the following raw materials in parts by weight: 66.45 parts of corn, 8 parts of wheat bran, 16 parts of soybean meal, 1 part of imported fish meal, 1 part of soybean oil, 0.6 part of stone powder, 0.5 part of calcium hydrogen phosphate, 0.35 part of table salt, 0.1 part of amino acid, 1 part of premix. The premix is vitamin A 0.1 part, vitamin D 3 0.045 parts, vitamin E 1 part, vitamin C 18 parts, vitamin B 12 0.002 parts, Vitamin B 6 0.2 parts, 0.5 parts of riboflavin, 1 part of calcium pantothenate, 2 parts of niacin, 0.01 parts of biotin, 0.04 parts of folic acid, 150 parts of choline chloride, 60 parts of ferrous sulfate, 50 parts of copper sulfate, 20 parts of manganes...

Embodiment 2

[0021] The feed without antibiotics fermented by microorganisms in the later stage of growing and finishing pigs is made by mixing the compound material and the compound fermented material, wherein the weight ratio of the compound material and the compound fermented material is: 94:6.

[0022] The batching material is prepared from the following raw materials in parts by weight: 68.44 parts of corn, 5 parts of wheat bran, 17 parts of soybean meal, 0.5 part of imported fish meal, 0.5 part of soybean oil, 0.6 part of stone powder, 0.45 part of calcium hydrogen phosphate, 0.4 part of table salt, Amino acid 0.11 part, premix 1 part; premix is vitamin A 0.15 part, vitamin D 3 0.055 parts, vitamin E 2 parts, vitamin C 25 parts, vitamin B 12 0.003 parts, Vitamin B 6 0.38 parts, riboflavin 0.6 parts, calcium pantothenate 0.8 parts, niacin 3 parts, biotin 0.02 parts, folic acid 0.05 parts, choline chloride 180 parts, ferrous sulfate 70 parts, copper sulfate 40 parts, manganese sulfa...

Embodiment 3

[0026] The feed without antibiotics fermented by microorganisms in the later stage of growing and finishing pigs is made by mixing the compound material and the compound fermented material, wherein the weight ratio of the compound material and the compound fermented material is: 96:4.

[0027] The ingredients are prepared from the following raw materials in parts by weight: 67.45 parts of corn, 8 parts of wheat bran, 16 parts of soybean meal, 1 part of imported fish meal, 1 part of soybean oil, 0.6 part of stone powder, 0.5 part of calcium hydrogen phosphate, 0.35 part of table salt, 0.1 part of amino acid, 1 part of premix. The premix is vitamin A 0.12 parts, vitamin D 3 0.05 parts, vitamin E 1.5 parts, vitamin C 20 parts, vitamin B 12 0.002 parts, Vitamin B 6 0.25 parts, riboflavin 0.55 parts, calcium pantothenate 1 part, niacin 2.5 parts, biotin 0.01 parts, folic acid 0.04 parts, choline chloride 200 parts, ferrous sulfate 55 parts, copper sulfate 45 parts, manganese su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com