Dialysis membrane material having physiological function and preparation method thereof

A physiological function, dialysis membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of sensitive sterilization technology, complex structure, poor blood compatibility, etc., and achieve good biocompatibility , the preparation process is simple, the structure is easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

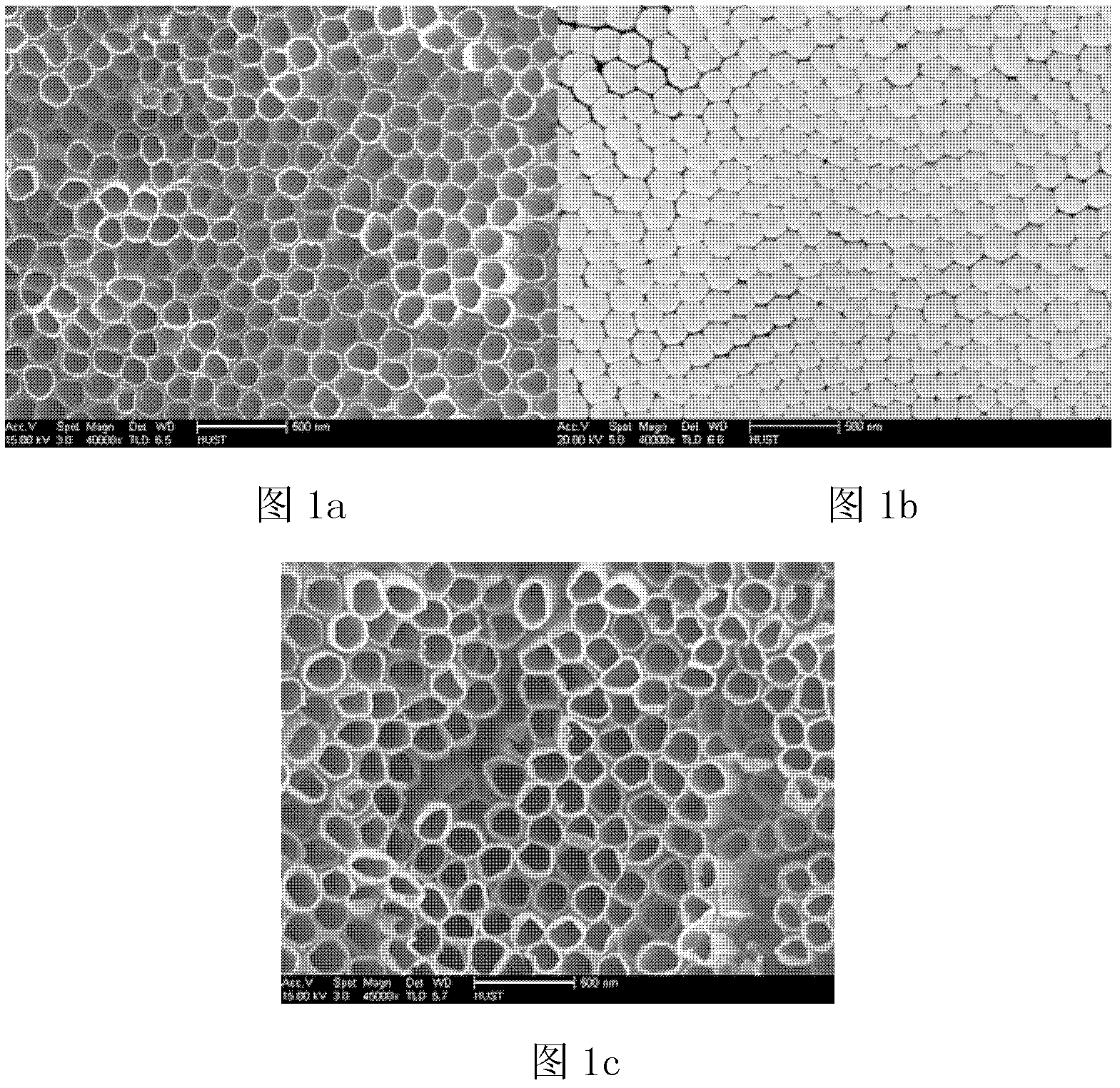

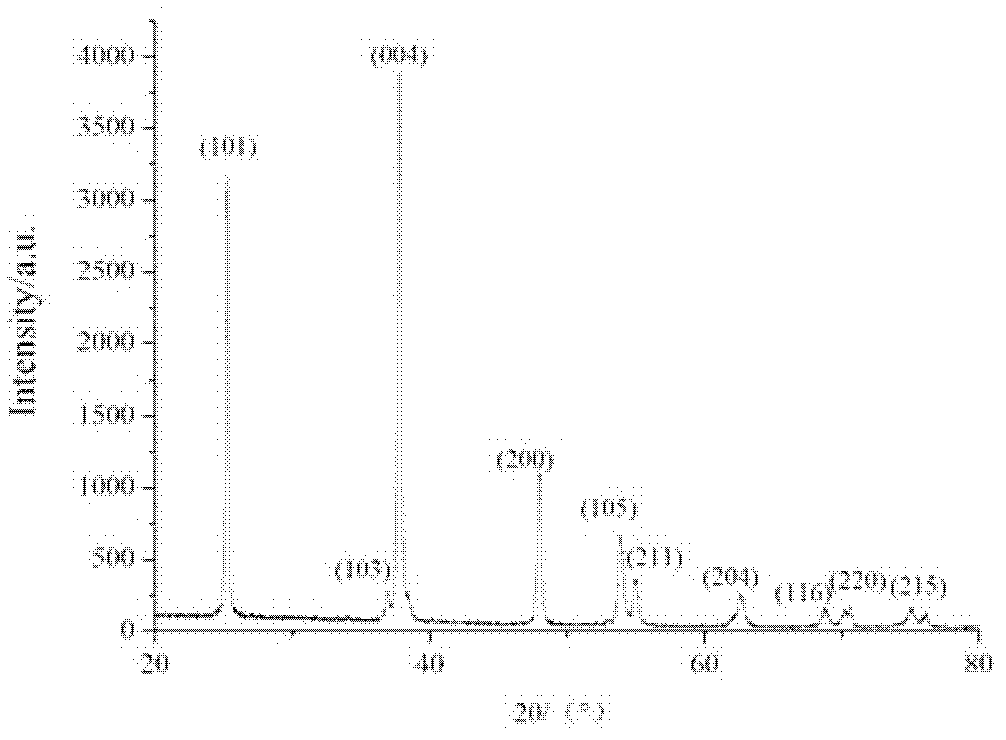

[0040] Firstly, a two-step anodizing method is adopted. The substrate is a titanium foil with a thickness of 0.5mm (purity is 99.8%), which is polished with sandpaper before anodizing. The electrolyte is 100ml ethylene glycol, 2ml water and 0.32g NH 4 F, the first step is anodizing at room temperature and 58V for 20min, then rapid annealing at 700°C, and then the second step of oxidation for 30h at the same electrolyte and 40V voltage to prepare a nanotube array with an open top and a closed bottom. After peeling off from the titanium substrate, it is treated with concentrated HF vapor for 10 minutes to 15 minutes, and the barrier layer at the bottom can be corroded, so as to obtain TiO with both ends transparent. 2 Nanotube array membranes (such as figure 1 ), with a diameter of about 70 nm and a length of about 60 μm. Finally, the film was annealed in a vacuum sintering furnace at 400°C, kept for 2 hours and then cooled in the furnace. XRD was used to detect that the TiO a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com