Method for synthesizing N-phenylmaleimide through catalysis of acid ionic liquid

A technology of acidic ionic liquid and maleimide, which is applied in the field of catalytic synthesis of N-phenylmaleimide by acidic ionic liquid, can solve the problems of inability to reuse and be difficult to remove, and achieves low production cost and high yield. The effect of good rate and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

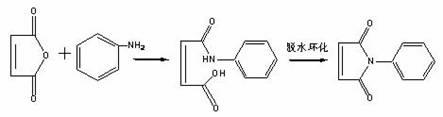

Image

Examples

Embodiment 1

[0022] According to the traditional method for preparing quaternary ammonium salt ionic liquids, triethylamine is added to a three-necked flask with a thermometer and a constant pressure dropping funnel, and concentrated sulfuric acid is added dropwise to it under ice bath conditions, and the rate of addition is controlled to keep the temperature of the system. Below 10°C, continue to react at below 10°C for two hours after the dropwise addition is completed. Filter after completion of the reaction, and the filtrate is rotary evaporated to obtain a brown viscous liquid, which is recorded as 1 # Quaternary ammonium salt ionic liquid catalyst.

[0023] With 50g of N-phenylmaleimide acid, 80g of toluene and 3 grams of the above 1 # Add the quaternary ammonium salt ionic liquid catalyst together to a 250ml three-necked flask equipped with a stirrer, a water separator and a reflux condenser, then add 0.25 grams of 2,6 di-tert-butylphenol, heat to boiling, and keep the temperature ...

Embodiment 2

[0025] Add 1 mol of choline chloride and 2 mol of zinc chloride into a closed three-necked flask with a thermometer, stir, and react at 60°C for 1 hour to obtain a colorless viscous liquid, which is recorded as 2 # Quaternary ammonium salt ionic liquid catalyst.

[0026] With 50g of N-phenylmaleimide acid, 80g of toluene and 8 grams of the above-mentioned 2 # Add the quaternary ammonium salt ionic liquid catalyst into a 250ml three-necked flask equipped with a stirrer, a water separator and a reflux condenser, then add 0.3 grams of triphenyl phosphite, and heat to boiling. At this time, the temperature is 112°C. Next, divide water while heating. After two hours, the water level in the water separator no longer rises. At this time, the reaction ends, and the liquid in the three-necked flask is layered. The upper layer is light yellow, and the lower layer is dark yellow oily. Pour off the upper liquid, and use 3% NaHCO 3 The aqueous solution is washed to neutrality, washed wit...

Embodiment 3

[0028] Add a certain amount of methanol into a closed three-necked flask with a thermometer, weigh one part of tetramethylammonium bromide and one part of sodium bisulfate, and stir at 40°C for 24 hours under a constant temperature magnetic stirrer. Filter, and the filtrate is rotary evaporated to obtain a yellow viscous liquid, which is recorded as 3 # catalyst.

[0029] With 50g of N-phenylmaleimide acid, 85g xylene and 15 grams of the above-mentioned 3 # Catalyst is added in the 250ml there-necked flask that agitator, water separator and reflux condenser are housed, add 0.25 gram of hydroquinone again, be heated to boiling, this moment temperature is 120 ℃, divide water while heating at this temperature, After two hours, the water level in the water separator no longer rises, and the reaction ends now, and the liquid in the three-necked flask is layered, the upper layer is light yellow, and the lower layer is dark yellow oily. Pour off the upper liquid, and use 3% NaHCO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com