Surface-controlled and polymerization-modification biological material and preparation method thereof

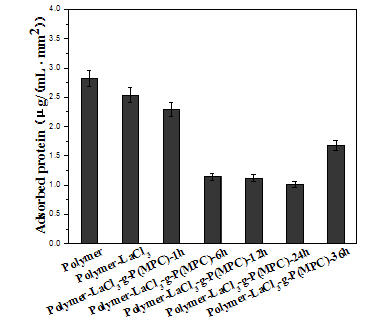

A technology of biomaterials and surface grafting, which is applied in the field of biomaterials modified by surface controllable polymerization and its preparation, can solve the problems of low grafting rate, high cost of ligands, toxicity, etc., and achieve simplified reaction conditions and excellent reaction effects Visible, readily available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

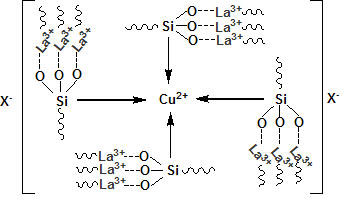

Method used

Image

Examples

Embodiment 1

[0051] Add 1% (wt%) LaCl to 10 silicone rubber diaphragms 3 -In ethanol aqueous solution, magnetically stirred for 6h, and vacuum dried at 110°C for 24h after taking out to obtain LaCl 3 ·6H 2 O-treated silicone rubber diaphragm. LaCl 3 ·6H 2 The O-treated silicone rubber diaphragm and 15 mL of secondary water were put into a three-necked flask, and 0.15 mL of chloromethyltriethoxysilane was added, stirred at room temperature for 10 min, and then 0.02 mL of benzoyl peroxide was added. The film that the surface has fixed the benzoyl peroxide initiator is put into the aqueous solution of 1mol / L ammonium phosphate zwitterion (R is methacrylate type), and adds CuCl 2 , the ratio of the amount of substance is: M 两性离子 :M 卤化铜 =120:7, and then nitrogen protection. The reaction was stirred at room temperature for 72h. Take out the diaphragm, wash it with water and dry it under vacuum.

Embodiment 2

[0053] Add 0.1% (wt%) LaCl to 10 silicon rubber diaphragms 3 -in ethanol aqueous solution, magnetically stirred for 1h, and vacuum dried at 110°C for 24h after taking out to obtain LaCl 3 ·6H 2 O-treated silicone rubber diaphragm. LaCl 3 ·6H 2 The O-treated polymer film and 5 mL of secondary water were put into a three-neck flask, and 0.05 mL of chloromethyltrimethoxysilane was added. After stirring for 5 min at room temperature, 0.002 mL of tert-butyl hydrogen peroxide was added. The film that the surface has fixed tert-butyl peroxide hydrogen initiator is put into the aqueous solution of 0.1mol / L ammonium phosphate zwitterion (R is methacrylate type), and adds CuBr 2 , the ratio of the amount of substance is: M 两性离子 :M CuBr2 =90:1, then nitrogen protection. The reaction was stirred at room temperature for 1 h. Take out the diaphragm, wash it with water and dry it under vacuum.

Embodiment 3

[0055] Add 0.2% (wt%) LaCl to 10 polyurethane diaphragms 3 - In aqueous ethanol solution, magnetically stirred for 2 hours, and then vacuum dried at 110°C for 24 hours to obtain LaCl 3 ·6H 2 O-treated polyurethane diaphragm. LaCl 3 ·6H 2 The O-treated polymer film and 6 mL of secondary water were put into a three-necked flask, and 0.05 mL of dichloromethyltrimethoxysilane was added. After stirring for 6 min at room temperature, 0.003 mL of tert-butyl hydrogen peroxide was added. The film that the surface has fixed tert-butyl peroxide hydrogen initiator is put into the aqueous solution of 0.2mol / L sulfonamide zwitterion (R is methacrylate type), and adds CuBr 2 , the ratio of the amount of substance is: M 两性离子 :M CuBr2 =95:2, then nitrogen protection. The reaction was stirred at room temperature for 6h. Take out the diaphragm, wash it with water and dry it under vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com