Composite material comprising nanoparticles and production of photoactive layers containing quaternary, pentanary and higher-order composite semiconductor nanoparticles

A technology of nano-particles and composite materials, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, photovoltaic power generation, etc., and can solve the problems of unreported and unimportant preparation of quaternary and quinary compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Synthesis of Cu in solution 2 ZnSnS 4 -Nanoparticles to prepare polycrystalline semiconductor layers

[0025] 1mmol (190.5mg) CuI, 0.5mmol (68.1mg) ZnCl 2 and 0.5mmol (313.2mg) SnI 4 Dissolve in 10ml oleylamine (or dodecylamine, nonylamine). Then 6 mmol (192.4 mg) of sulfur (sublimed) dissolved in 3 ml of oleylamine (or dodecylamine, nonylamine) was added and the solution was heated at 220° C. for 60 minutes. For purification, the particles were precipitated in methanol after cooling of the reaction solution and subsequently centrifuged. The obtained nanoparticles were dried at 60 °C and subsequently dissolved in various solvents such as chloroform, dichloromethane, toluene or hexane for further analysis or testing.

[0026]The nanoparticle solution was coated onto a substrate, and the resulting layer was subsequently heated at 500° C. for 2 hours. Thus a polycrystalline layer is formed.

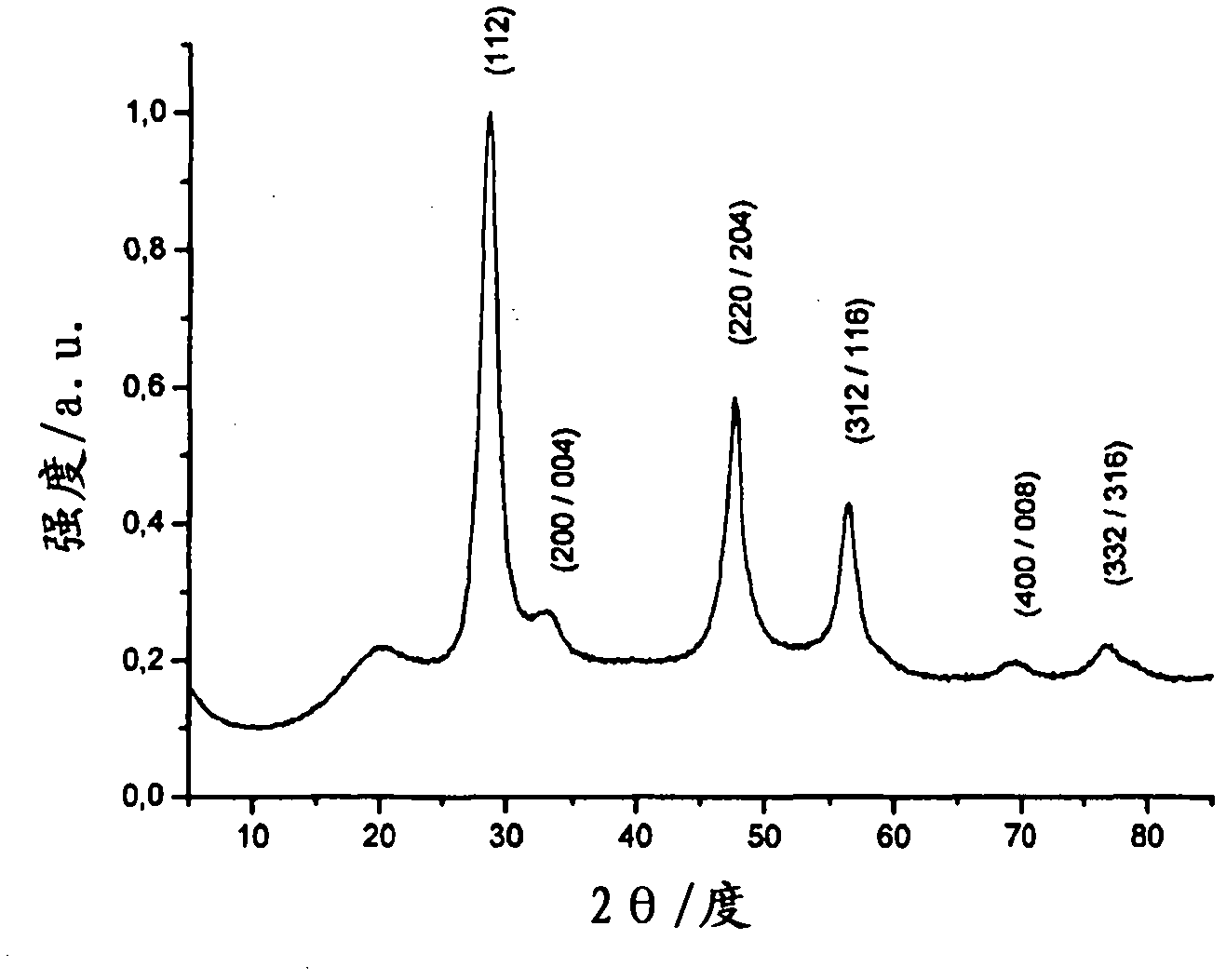

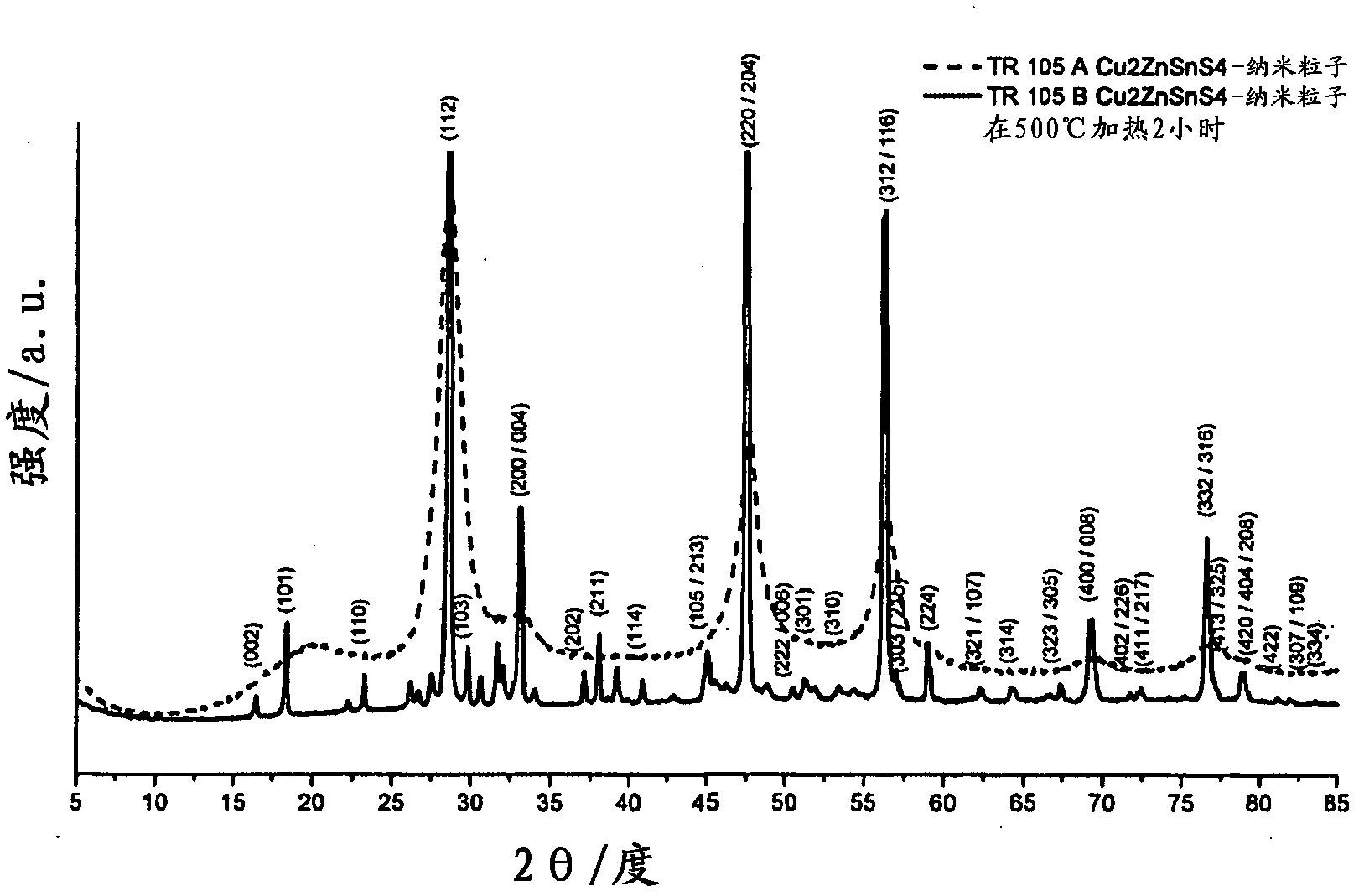

[0027] Diffraction patterns of nanoparticles (TR 105A) and poly...

Embodiment 2

[0034] Embodiment 2: prepare Cu 2 ZnSnS 4 - Nanoparticle layer

[0035] In an ultrasonic bath, 0.165mmol (20.2mg) CuAc, 0.0825mmol (18.1mg) ZnAc 2 , 0.0825mmol (29.3mg) SnAc 4 And 1.65mmol (125.6mg) thiourea was dissolved in 2ml pyridine. The pale yellow solution was added dropwise onto a glass substrate. Alternatively, the coating solution can also be applied by spraying techniques such as air brushing.

[0036] The layer thus obtained was heated at 100°C for 8 minutes, at 150°C for 8 minutes and at 200°C for 8 minutes under an inert gas atmosphere. This changes the color of the layer to red, then brown, and finally black. The material thus obtained was analyzed by means of X-ray diffraction. Figure 5 The diffractograms of the CZTS-layer formed after (A) temperature treatment at 200°C and (B) after temperature treatment at 500°C are shown in .

[0037] Broad peaks at 28.4° (112), 47.3° (220 / 204), 56.1° (312 / 116), 69.1° (400 / 008) and 76.3° (332 / 316) originate from Cu ...

Embodiment 3

[0040] Embodiment 3: preparation poly-3-hexylthiophene (P3HT) / Cu 2 ZnSnS 4 - Bulk heterojunction solar cells

[0041] Cu obtained in the synthesis of embodiment 1 2 ZnSnS 4 - Nanoparticles used in combination with the electroactive polymer P3HT as a donor for the active layer of a nanocomposite solar cell. To this end, excess stabilizer (oleylamine) was first removed with pyridine by three ligand exchanges. Then prepare P3HT / Cu in chloroform 2 ZnSnS 4 - Solution (polymer concentration: 4 mg / ml; nanoparticle concentration: 12 mg / ml).

[0042] The solar cells are constructed in layers on an ITO-coated glass substrate. As a first layer, polyethylenedioxythiophene:polystyrenesulfonate (PEDOT:PSS) was applied by spin coating to level the ITO-electrode. The applied layer is dried at about 80° C. under inert gas. As the next layer, apply the active layer again by spin coating (P3HT / Cu in chloroform 2 ZnSnS 4 - solution). After another drying step under inert gas (15 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap