Method for preparing titanium dioxide-zinc oxide nuclear shell structure nanometer fiber membrane for dye sensitized battery

A technology of dye-sensitized cells and nanofiber membranes, applied in photosensitive equipment, circuits, photovoltaic power generation, etc., to achieve the effects of improving conversion efficiency, increasing collection efficiency, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

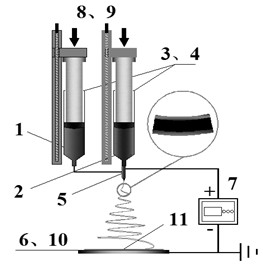

Method used

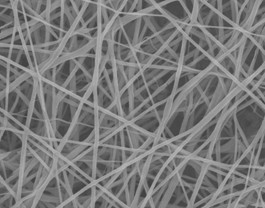

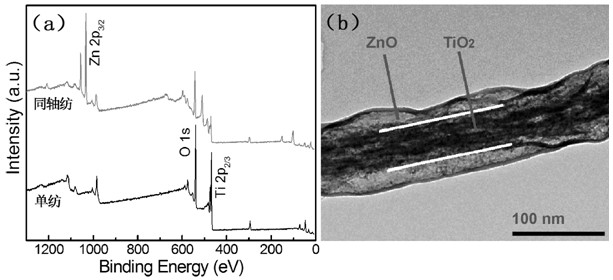

Image

Examples

Embodiment 1

[0024] 0.68g polymer PVAc was added to 4ml DMF organic solvent to form a solution with a mass percentage of 15wt.%, and 1ml Triton X-100, 1.36g TiP, and 0.68g C 4 h 6 o 4 Zn·2H 2 O, clear and viscous TiO was obtained by magnetic stirring for 8 h 2 / ZnO composite precursor spin-coating solution; and use a spin-coating instrument to spin-coat it on the FTO conductive glass cleaned ultrasonically by acetone and absolute ethanol to form a layer of spin-coating, the spin-coating instrument speed is 2000r min -1 , the spin coating time used is 30s.

[0025] 0.52g PVAc was added to 4ml DMF to form a solution with a mass percentage of 11.5wt.%. The same solution was prepared in two parts, i.e. solution I and solution II; in solution I was added 0.6ml Triton X-100 and 0.52g C 4 h 6 o 4 Zn·2H 2 O, magnetic stirring for 8h to obtain the precursor spinning solution 1 of ZnO. Add 0.6ml Triton X-100, 0.4ml HAc, and 1.04g TiP to solution II, and stir magnetically for 8 hours to obta...

Embodiment 2

[0028] 0.68g polymer PVAc was added to 4ml DMF organic solvent to form a solution with a mass percentage of 15wt.%, and 1ml Triton X-100, 1.36g TiP, and 0.68g C 4 h 6 o 4 Zn·2H 2 O, clear and viscous TiO was obtained by magnetic stirring for 8 h 2 / ZnO composite precursor spin-coating solution; and use a spin-coating instrument to spin-coat it on the FTO conductive glass cleaned ultrasonically by acetone and absolute ethanol to form a layer of spin-coating, the spin-coating instrument speed is 2000r min -1 , the spin coating time used is 30s.

[0029] 0.52g PVAc was added to 4ml DMF to form a solution with a mass percentage of 11.5wt.%. The same solution was prepared in two parts, i.e. solution I and solution II; in solution I was added 0.6ml Triton X-100 and 0.52g C 4 h 6 o 4 Zn·2H 2 O, magnetic stirring for 8h to obtain the precursor spinning solution 1 of ZnO. Add 0.6ml Triton X-100, 0.4ml HAc, and 1.04g TiP to solution II, and stir magnetically for 8 hours to obta...

Embodiment 3

[0032] 0.68g polymer PVAc was added to 4ml DMF organic solvent to form a solution with a mass percentage of 15wt.%, and 1ml Triton X-100, 1.36g TiP, and 0.68g C 4 h 6 o 4 Zn·2H 2 O, clear and viscous TiO was obtained by magnetic stirring for 8 h 2 / ZnO composite precursor spin-coating solution; and use a spin-coating instrument to spin-coat it on the FTO conductive glass cleaned ultrasonically by acetone and absolute ethanol to form a layer of spin-coating, the spin-coating instrument speed is 2000r min -1 , the spin coating time used is 30s.

[0033] 0.52g PVAc was added to 4ml DMF to form a solution with a mass percentage of 11.5wt.%. The same solution was prepared in two parts, i.e. solution I and solution II; in solution I was added 0.6 ml Triton X-100 and 0.52g C 4 h 6 o 4 Zn·2H 2 O, magnetic stirring for 8h to obtain the precursor spinning solution 1 of ZnO. Add 0.6ml Triton X-100, 0.4ml HAc, and 1.04g TiP to solution II, and stir magnetically for 8 hours to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com