Magnetic sulphonated carbon-based nanofiber, preparation method for same and application thereof

A technology for sulfonating carbonyl nanometer and carbon-based fibers, which is applied in chemical instruments and methods, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of excessive waste liquid, high preparation cost, poor stability, etc., and achieve simple process, The effect of wide range of raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

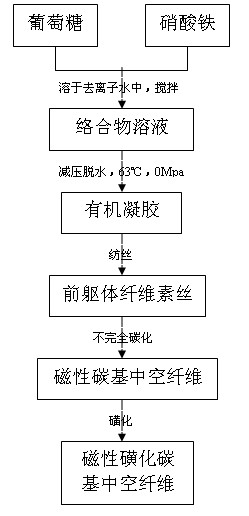

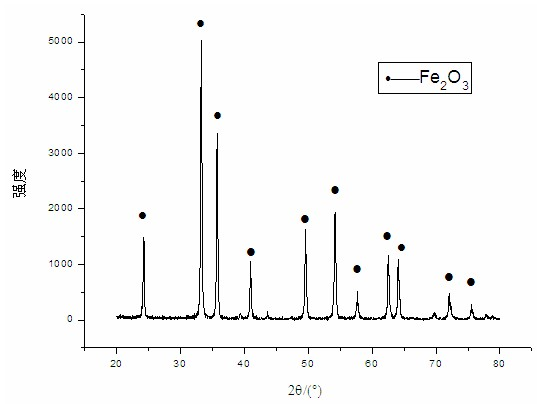

[0030] Example 1 (magnetic sulfonated carbon-based fiber):

[0031] Step 1: get 8g ferric nitrate (Fe(NO 3 ) 3 9H 2 O), 9g glucose (D-(+)-Glucose), mixed in 400ml deionized water, Fe 3+ The molar concentration of G is 0.0495mol / L, and the molar concentration of G is 0.1135mol / L The raw material mass ratio is: Fe 3+ :G=8:9, then perform magnetic stirring for 24 hours.

[0032] Step 2: Then put the precursor solution into a vacuum rotary evaporator, depressurize at 70°C, and dehydrate it for 45 minutes at a pressure of 0.05Mpa to obtain a gel colloid.

[0033] Step 3: Put the gel obtained in step 2 into an oven, dry and dehydrate at 60°C, place it in the oven for 1 hour, then pull the gel into gel cellulose filaments, place the cellulose filaments Dry in a crucible at 100°C.

[0034] Step 4: The fiber precursor is heated up to 400°C at a heating rate of 3°C / min in an air atmosphere, and kept for 5 hours; naturally cooled to obtain the target carrier Fe / C fiber with a di...

Embodiment 2

[0037] Example 2 (magnetic sulfonated carbon-based fibers):

[0038] Step 1: get 14g ferric nitrate (Fe(NO 3 ) 3 9H 2 O), 18g glucose solid powder (D-(+)-Glucose), mixed in 500ml deionized water, Fe 3+ The molar concentration of G is 0.0693mol / L, the molar concentration of G is 0.1818mol / L, and the mass ratio of raw materials is: Fe 3+ :G=7:8, then perform magnetic stirring for 24 hours.

[0039] Step 2: Then put the precursor solution into a vacuum rotary evaporator, depressurize at 63°C, dehydrate at 0 MPa, and dehydrate for 60 minutes to obtain a gel colloid.

[0040] Step 3: The gel obtained in step 2 was spun on a self-made gel spinning machine, and the collected cellulose filaments were dried in an oven at 90°C.

[0041] Step 4: Heat the fiber precursor to 350°C at a heating rate of 3°C / min in an air atmosphere, and keep it for 8 hours; cool naturally to obtain the target carrier Fe / C-SO with a diameter of micron 3 H fiber.

[0042] Step 5: Immerse 2 g of the c...

Embodiment 3

[0044] Example 3 (magnetic sulfonated carbon-based fibers):

[0045] Step 1: get 12g ferric nitrate (Fe(NO 3 ) 3 9H 2 O), 14g glucose solid powder (D-(+)-Glucose), mixed in 500ml deionized water, Fe 3+ The molar concentration of G is 0.0594mol / L, and the molar concentration of G is 0.1413mol / L The raw material mass ratio is: Fe 3+ :G=6:7, then perform magnetic stirring for 24 hours.

[0046] Step 2: Then put the precursor solution into a vacuum rotary evaporator, depressurize at 63°C, the pressure is about 0Mpa, and dehydrate for 70 minutes to obtain a gel colloid.

[0047] Step 3: The gel obtained in step 2 is spun on a gel spinning machine, and the collected cellulose filaments are dried in an oven at 90°C.

[0048] Step 4: Heat the fiber precursor to 380°C at a heating rate of 3°C / min in an air atmosphere, and keep it warm for 6 hours; naturally cool to obtain the target carrier Fe / C-SO with a diameter of micron 3 H fiber.

[0049] Step 5: Immerse 2 g of the carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com