Method for electrolysis, reduction and desulfurization of coal water slurry

A technology of coal water slurry and coal slurry, which is applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of low utilization rate, harsh conditions, coal quality destruction cost, etc., and achieve energy saving, mild reaction, reduction of material consumption and The effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

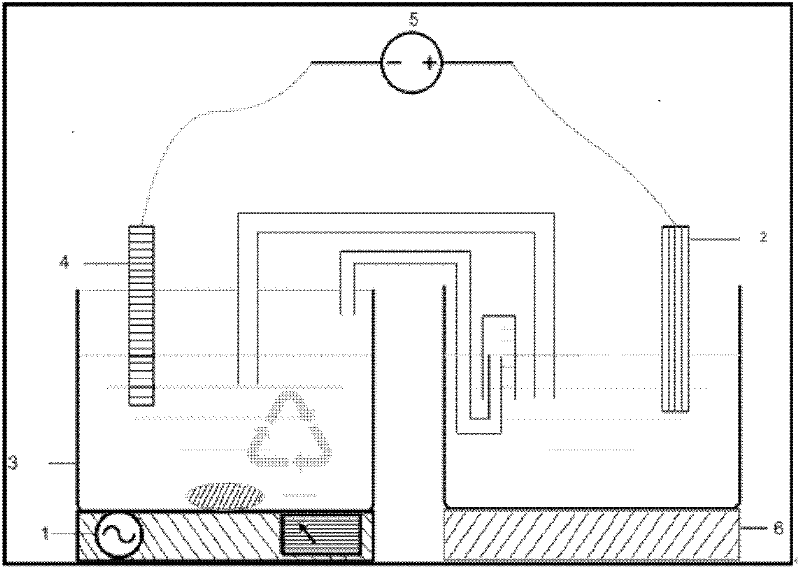

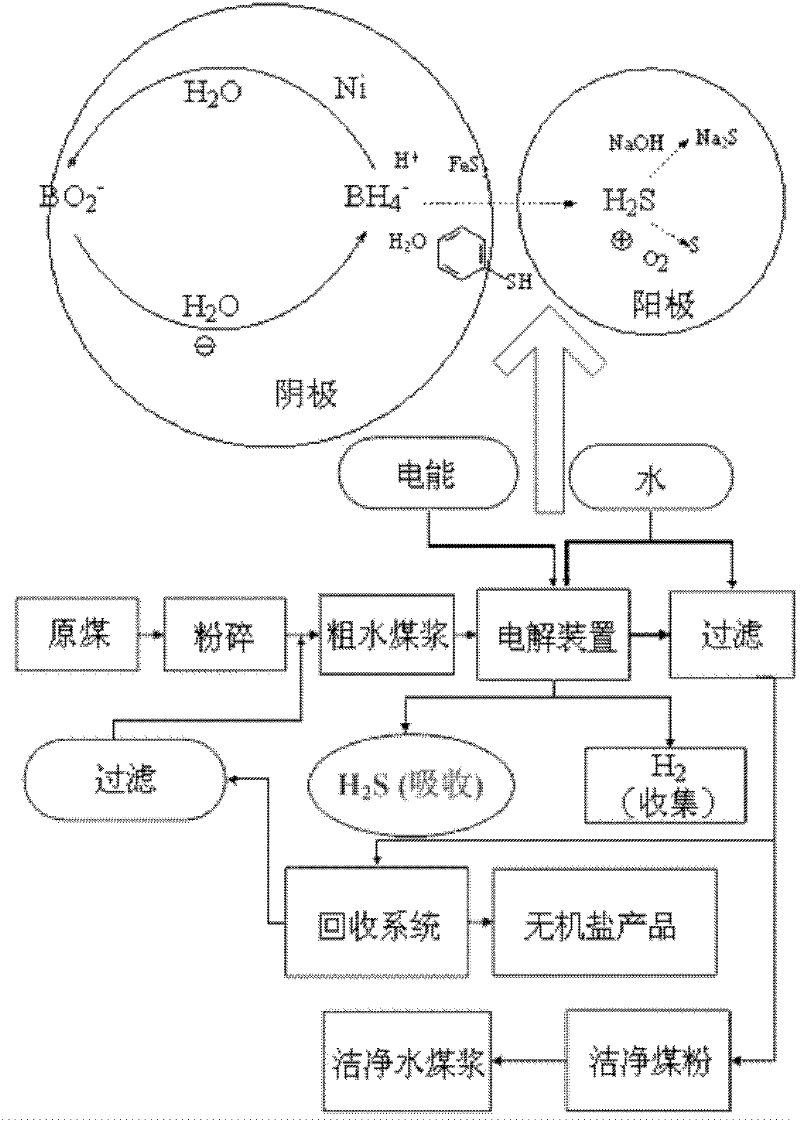

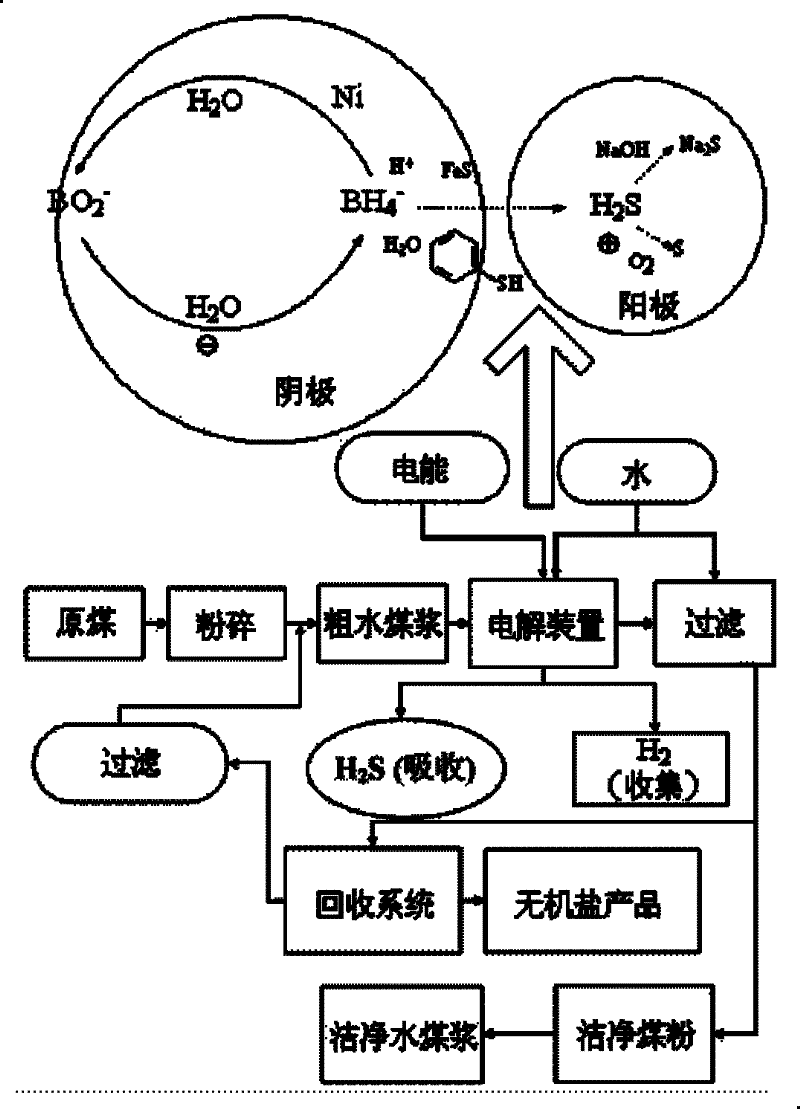

[0036] The diagram of the deep desulfurization device for electrolytic reduction of coal water slurry is shown in Fig. figure 1 As shown, the process flow and schematic diagram of the deep desulfurization process and principle of coal-water slurry electrolytic reduction are shown in figure 2 As shown, using sodium metaborate as the electrolyte, sodium metaborate is converted into sodium borohydride through cathodic reduction reaction, and the sulfur in coal-water slurry is finally reduced to volatile hydrogen sulfide gas or S 2- , and then through filtration and elution to achieve desulfurization of coal water slurry before combustion. The graphite plate in the anode electrolysis cell 6 is the anode electrode 2, and the lead plate in the cathode electrolysis cell 3 is the cathode electrode 4. The generated hydrogen sulfide passes through the air duct and is finally introduced into the anolyte, where soluble sulfate is finally formed and absorbed. Add sodium metaborate and s...

Embodiment 2

[0038] Experimental method is as shown in embodiment 1, under the situation that does not add nickel chloride metal catalyst, it is 5g / L to get supporting electrolyte sodium metaborate concentration in the cathode electrolytic cell, and sodium hydroxide concentration is 1g / L and coal-water slurry concentration is 30g / L (particle size 120 mesh, sulfur content 0.5%), stir evenly, stirring speed is 300rpm; add sodium hydroxide solution concentration to 1g / L in the anode electrolytic cell; V, at the same time, turn on the magnetic stirrer to stir the solution in the electrolytic cell at a constant speed of 400rpm, and carry out the electrolytic reaction for 1h; after the electrolytic reaction is completed, filter and wash the product in the cathode electrolytic cell to obtain a low-sulfur and low-ash coal-water slurry solid. After the electrolysis is completed, the desulfurization rate of the coal water slurry is about 16.5%.

Embodiment 3

[0040]Experimental method is as shown in embodiment 1, under the situation of adding nickel chloride metal catalyst 2mmol / L, get supporting electrolyte sodium metaborate 20g / L in the cathode electrolytic cell, sodium hydroxide concentration 1g / L and coal-water slurry concentration are 10g / L (particle size 80 mesh, sulfur content ≥ 0.5%), stir evenly, stirring speed is 400rpm; add sodium hydroxide solution concentration to 5g / L in the anode electrolytic cell; feed the voltage 2.5V into the anode and cathode electrolytic cell At the same time, turn on the magnetic stirrer to stir the solution in the electrolytic cell at a constant speed of 300rpm, and carry out the electrolytic reaction for 3 hours; after the electrolytic reaction is completed, filter and wash the product in the cathode electrolytic cell to obtain a low-sulfur and low-ash coal-water slurry solid. After the electrolysis is completed, the desulfurization rate of the coal-water slurry is 48%, and about 24ml of hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com