Honeycomb-shaped microorganism carrier and preparation method thereof

A microbial carrier and honeycomb technology, which is applied in the field of honeycomb microbial carrier and its preparation, can solve the problems that the immobilized microorganism technology cannot be widely used in wastewater, the microbial growth environment is single, and the material cost is high, and the material cost is low and the biomass is high. The effect of many, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

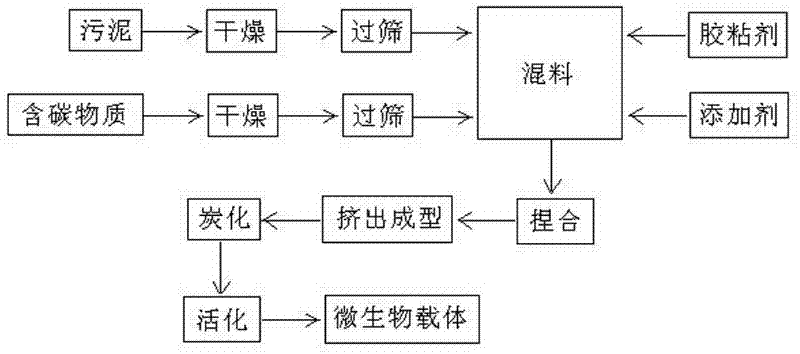

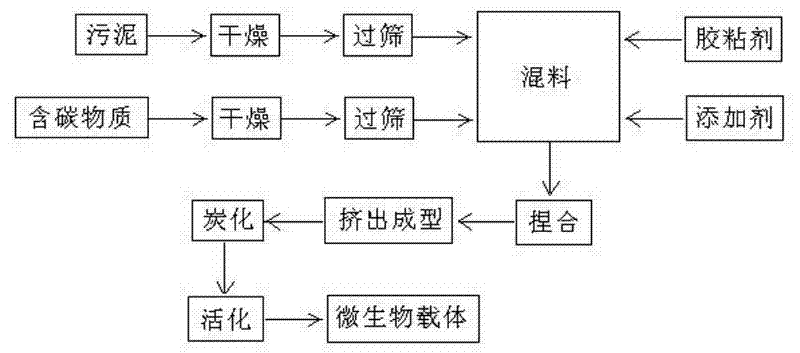

Method used

Image

Examples

Embodiment 1

[0017] A honeycomb microbial carrier is composed of the following raw materials in mass percentage: 60% of domestic sewage sludge, 20% of straw or sawdust, 12% of coal tar or epoxy resin, and 8% of calcium carbonate or hydroxyapatite. The method for preparing the honeycomb-shaped microbial carrier includes the following steps: (1) drying and grinding domestic sewage sludge and straw or sawdust, and the particle size is subject to 100% passing through a 100-mesh sieve; (2) drying the sludge, straw Or sawdust, coal tar or epoxy resin, calcium carbonate or hydroxyapatite are mixed according to the above mass percentage; (3) The mixture obtained in step (2) is fully stirred and kneaded in a kneader, and then the kneaded plastic clay The material is molded with a honeycomb steel mold on an extruder with a pressure of 10Mpa to make a cylindrical or strip-shaped honeycomb body with a smooth surface and a complete honeycomb channel structure, and then dried at 110°C for 20 hours; (4) T...

Embodiment 2

[0019] A honeycomb microbial carrier is composed of the following raw materials in mass percentage: 50% of industrial wastewater sludge, 30% of waste paper, 18% of methyl cellulose or phenolic resin, and 2% of disodium edetate. The method for preparing the honeycomb microbial carrier includes the following steps: (1) drying and grinding industrial wastewater sludge and waste paper, and the particle size shall be 100% through a 100-mesh sieve; (2) industrial wastewater sludge, Waste paper, methyl cellulose or phenolic resin, and disodium edetate are mixed according to the above mass percentage; (3) The mixture obtained in step (2) is fully stirred and kneaded in a kneader, and then the kneaded plastic The mud material is molded with a honeycomb steel mold on an extruder with a pressure of 15Mpa to make a cylindrical or strip-shaped honeycomb body with a smooth surface and a complete honeycomb channel structure, and then dried at 130°C for 24 hours; (4) will get The dry honeycom...

Embodiment 3

[0021] A honeycomb microbial carrier, which is composed of the following raw materials in mass percentage: 40% of feedwater sludge, 35% of sawdust and waste paper mixed in any proportion, 20% of sodium carboxymethyl cellulose, mixed with calcium carbonate and hydroxyl Apatite 5%. The method for preparing the honeycomb-shaped microbial carrier includes the following steps: (1) drying and grinding feedwater sludge and carbon-containing substances, and the particle size is subject to 100% passing through a 100-mesh sieve; (2) drying the sludge, carbon-containing substances Substances, adhesives, and additives are mixed according to the above mass percentage; (3) The mixture obtained in step (2) is fully stirred and kneaded in a kneader, and then the kneaded plastic clay is used on the extruder with a honeycomb steel mould. Press molding to make a columnar or strip-shaped honeycomb body with smooth surface and complete honeycomb channel structure, and then dry at 120°C for 24 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com