Preparation method for dendritic-nanometer-structure polyaniline air-sensitive sensor

A nano-structure, polyaniline gas technology, applied in the field of sensors, can solve the problems of difficult processing and molding, difficult processing and application, high melting point, and achieve the effects of not easy to break, low power consumption, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

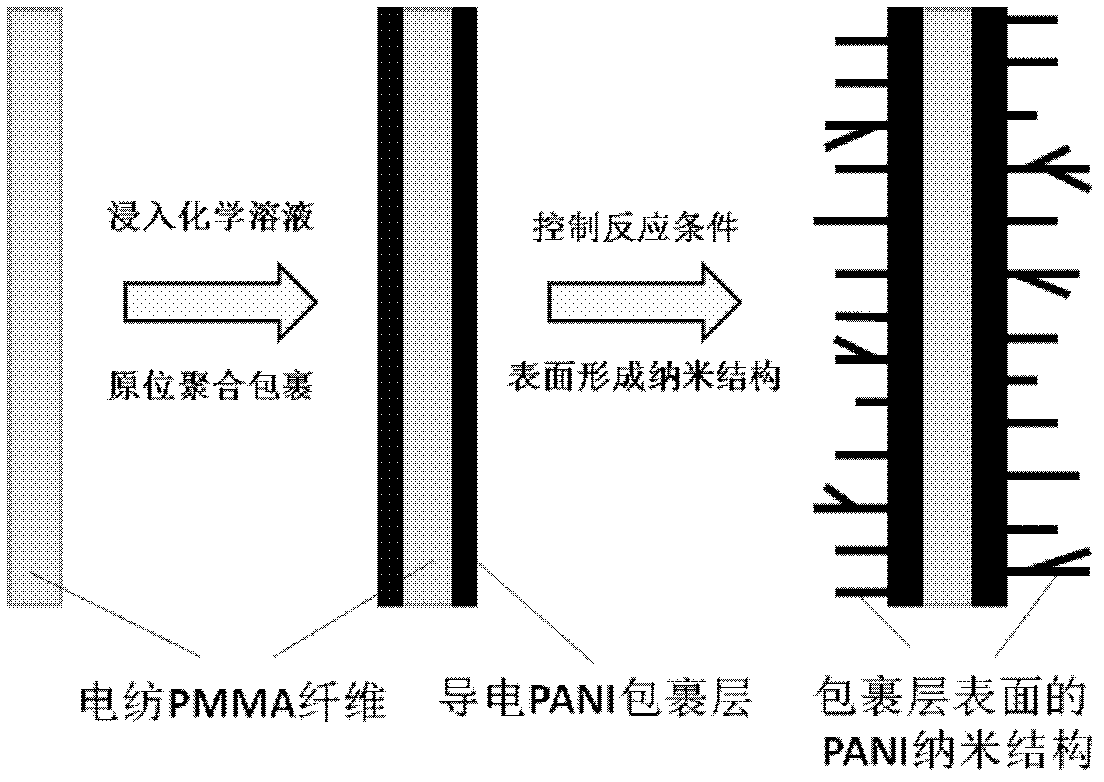

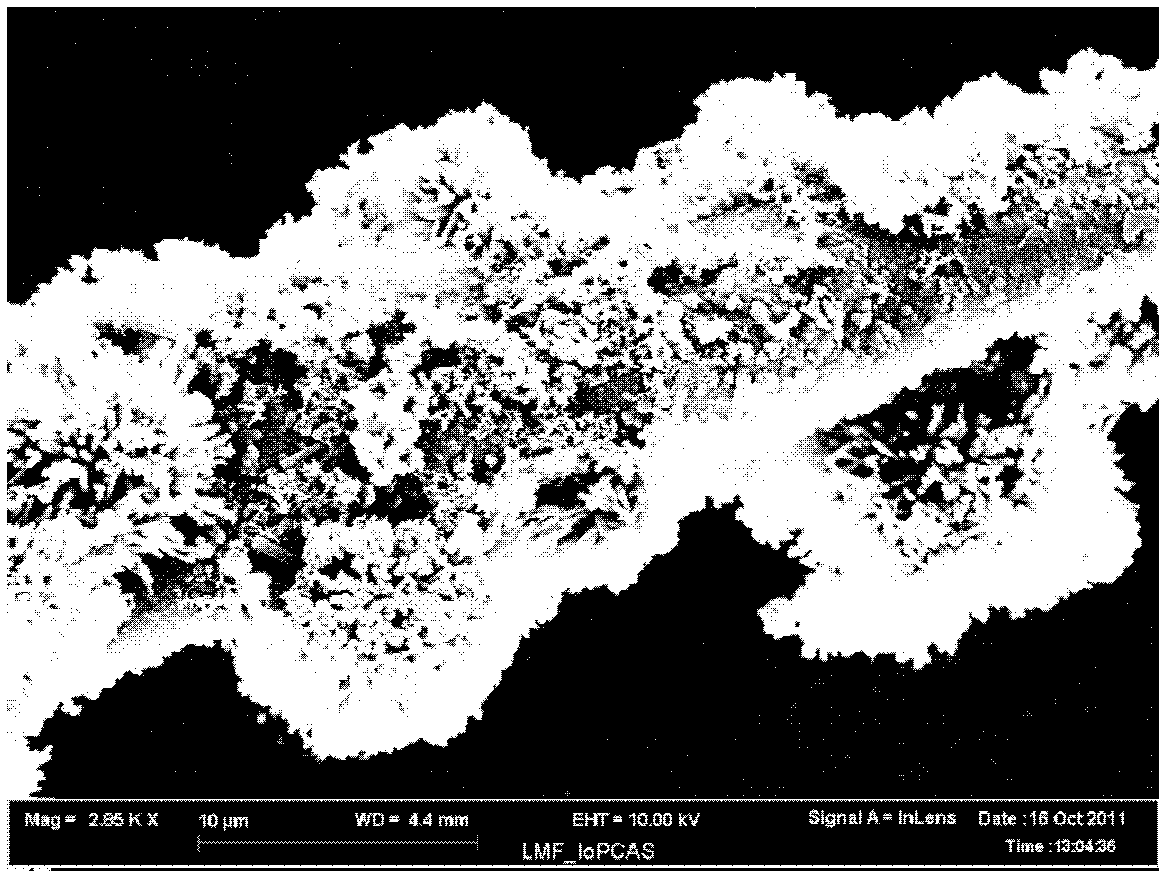

[0012] The first step of this embodiment: the electrospinning method prepares polymethyl methacrylate PMMA nanofiber, selects existing electrospinning device for use, and preparation mass percent is the PMMA spinning solution (1.7 gram PMMA (molecular weight is 350,000), 4.15 grams of tetrahydrofuran, 4.15 grams of dimethylformamide); the distance between the emitter (needle, inner diameter 0.6 mm) and the receiver (aluminum foil) of the electrospinning device is 12 cm, and the spinning voltage is 10 To 14 kV, transfer the PMMA non-woven fabric fiber prepared by electrospinning to the hollow plastic sheet and fix it with double-sided adhesive tape, as a template for the preparation of coaxial polyaniline fiber; the second step: in-situ polymerization on the surface of PMMA nanofiber Generate polyaniline nanostructures, use 0.02 mole of aniline, 0.02 mole of ammonium persulfate (oxidant), 0.01 mole of sulfosalicylic acid (dopant) and 100 milliliters of deionized water to make po...

Embodiment 2

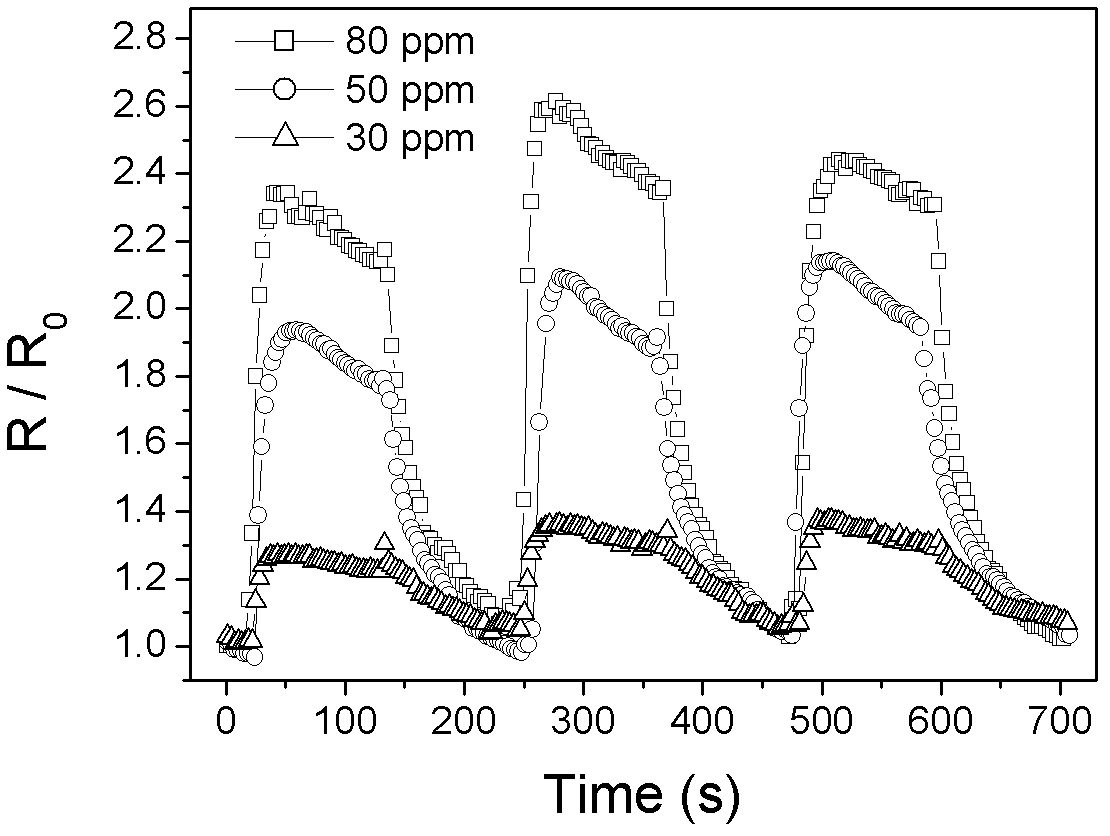

[0014] This embodiment is a test of the sensing performance of the coaxial fiber gas sensor prepared by the present invention to ammonia: the dendritic nanostructure polyaniline coaxial fiber sample is connected with copper wire and silver glue to the electrode and placed in the gas sensor test device , connect the resistance measuring instrument and power supply; before the measurement, fill the gas sensor test device with nitrogen gas, fully remove other gases in the device, and then fill the device with ammonia gas to be tested after the sample resistance is stable; the sample measurement voltage It is 4 volts, and the ammonia gas charging and deflation cycle is 240 seconds, of which 120 seconds each for inflation and deflation; when inflating, turn off the nitrogen, and fill in the ammonia; cycle, while using a computer to record the sample resistance R and the initial resistance R 0 The resistance ratio R / R 0 The change curve with time, that is, the response curve of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com