Method for manufacturing organic polymer optical waveguide amplifier by ultraviolet nanoimprint lithography

A technology of optical waveguide amplifier and nanoimprinting, which is applied in the direction of optical waveguide light guide, light guide, optics, etc., to achieve the effects of improving process precision and efficiency, small line width, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

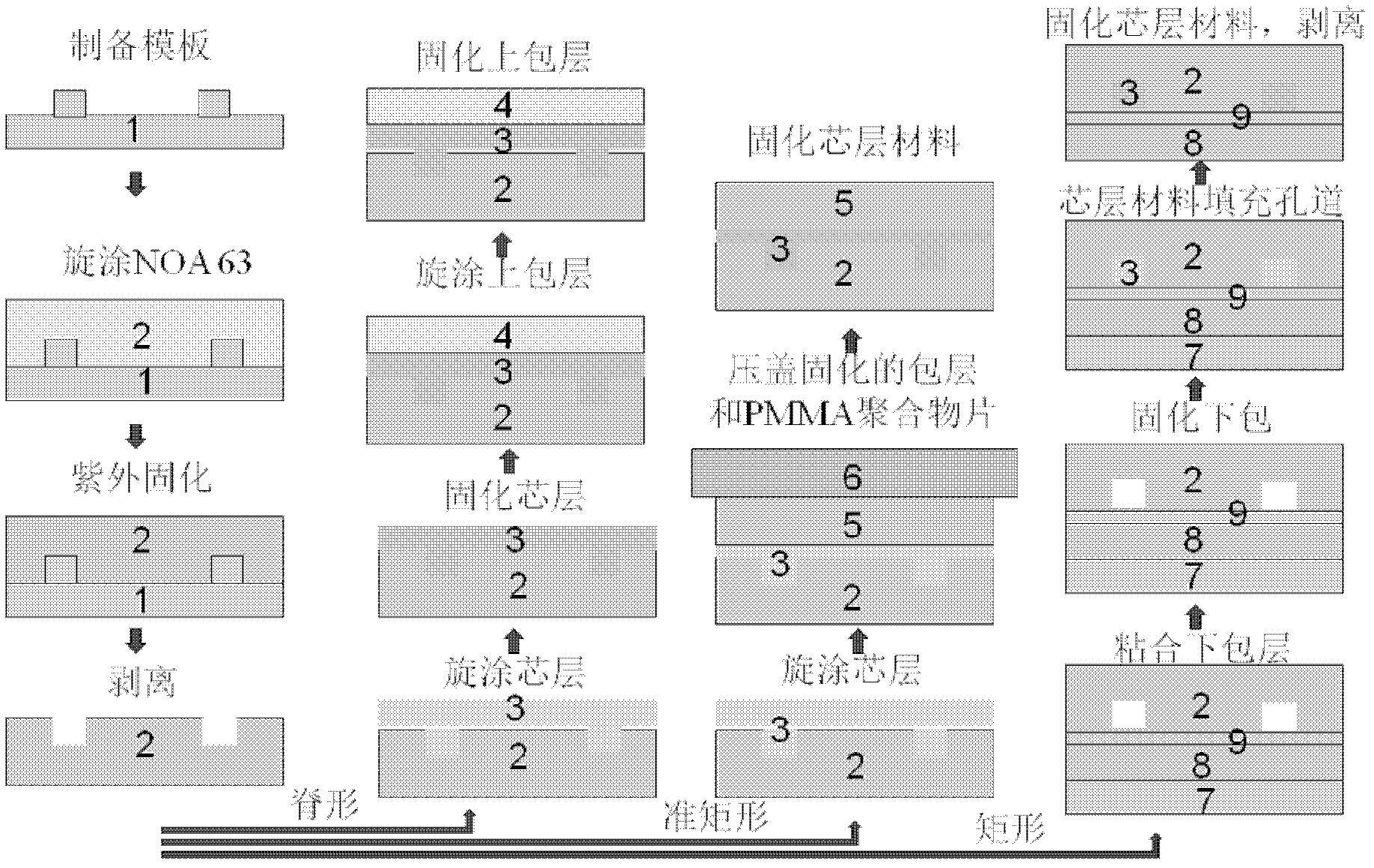

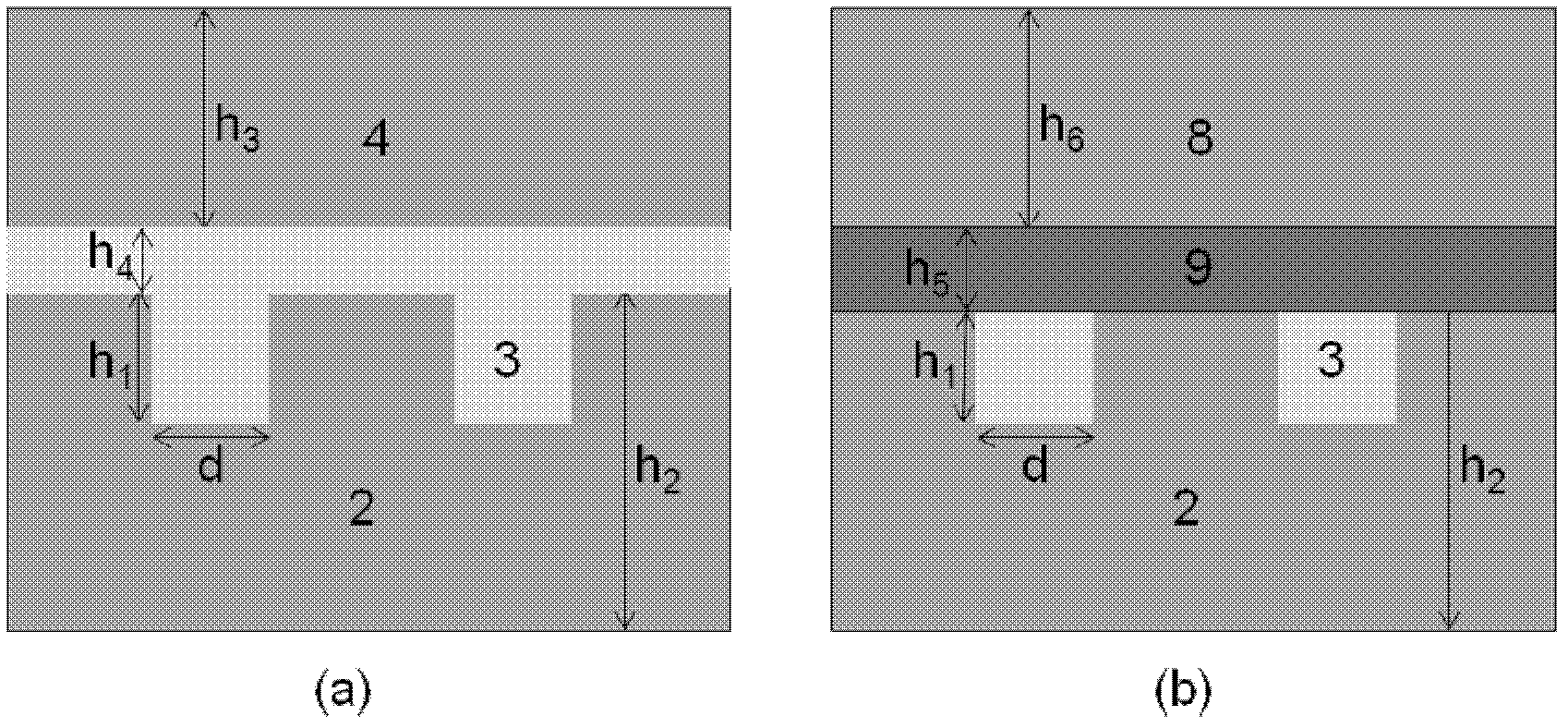

[0045] Example 1: Si Template Nanoimprint Ridged Er 1.2 Yb 0.8 (PBa) 6 (Phen) 2 EDWA

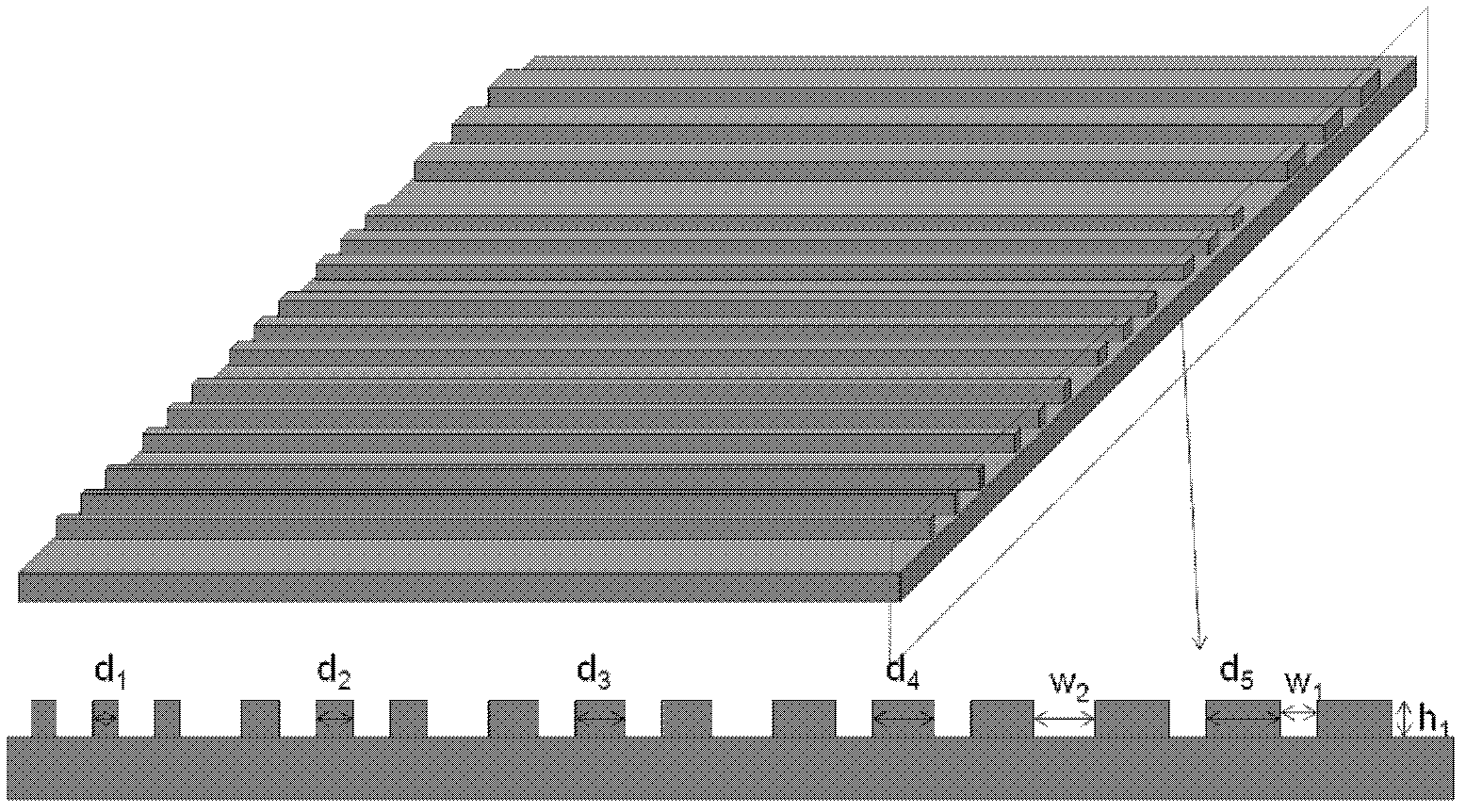

[0046] Prepare a Si template (1) with a raised waveguide pattern, the waveguide length (L) is 3cm, there are 5 groups of waveguide arrays, each group of waveguide arrays includes 3 waveguides, and the interval of each waveguide (w 1 ) is 200 microns, the width (d) of each waveguide in each group array is 1 μm, 2 μm, 4 μm, 6 μm and 8 μm respectively, the height (h1) of the waveguide is 3 microns, the spacing of the waveguide array (w 2 ) is 400 μm;

[0047] Polymer material NOA63 (without diluting toluene) is coated on the Si template (1) with the raised waveguide pattern that has been treated (wipe with acetone first, then with ethanol, and finally with deionized water), at 1500 rpm Rotate at a speed of 1 minute, and the rotation time is 30 seconds to obtain a lower cladding (2) with a thickness of 45 microns, and then peel off the lower cladding (2) from the Si template (1);

[0048] ...

Embodiment 2

[0051] Example 2: Preparation of ridge-shaped ErYb(DBM) by nanoimprinting of polymer template 3 (MA) / NOA61EDWA

[0052] After cleaning (cleaning with acetone first, then ethanol, and finally deionized water) SiO 2 Spin-coat SU-8 material on top, rotate at a speed of 3000 rpm, and spin for 30 seconds to obtain a film with a thickness of about 4.5 microns. After baking at 65°C (10 minutes) and 90°C (20 minutes) , exposed under a 150W, 365nm wavelength mercury lamp for 3 minutes, followed by post-baking at 150°C (30 minutes) to enhance the bonding force between the material and the substrate. Then spin-coat a layer of SU-8 material, rotate at a speed of 2000 rpm for 30 seconds, and obtain a film of about 6 microns. After 65°C (10 minutes), 90°C (20 minutes) before and after After baking, under the mercury lamp of 350W, 365nm wavelength, the photolithography of the plate is carried out, the exposure time is 3 minutes, and then the middle baking is carried out at 65°C (10 minutes...

Embodiment 3

[0056] Example 3: Si template imprinting quasi-rectangular ErYb(DBM) 3 (Phen) / SU-8EDWA

[0057] Prepare a Si template (1) with a raised waveguide pattern, the length (L) is 3 cm, a total of 5 waveguide arrays, the width (d) of each array is 8 μm, 6 μm, 4 μm, 2 μm and 1 μm, and the height of the waveguide (h1) is 4 microns, the pitch of the waveguide array (w 2 ) is 400 microns; each waveguide array includes 3 waveguides, and the interval of each waveguide (w 1 ) is 200 microns.

[0058] Polymer material NOA63 (without diluting toluene) is coated on the Si template (1) with raised waveguide pattern that has been treated (wiping with acetone first, then ethanol, and finally rinsed with deionized water), at 1500 rpm Spinning at a rpm of 30 sec for a 45 micron thick lower cladding (2).

[0059] Put the spin-coated lower cladding layer (2) under a 400W mercury lamp for ultraviolet curing (ultraviolet nanoimprinting), the curing distance is 30cm, and the curing time is 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com