High-density capacitor and electrode leading-out method thereof

A technology of electrode extraction and capacitors, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of large equivalent series inductance, low working voltage, incompatibility, etc., and achieve small equivalent series inductance, large capacitance, Easily Integrate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

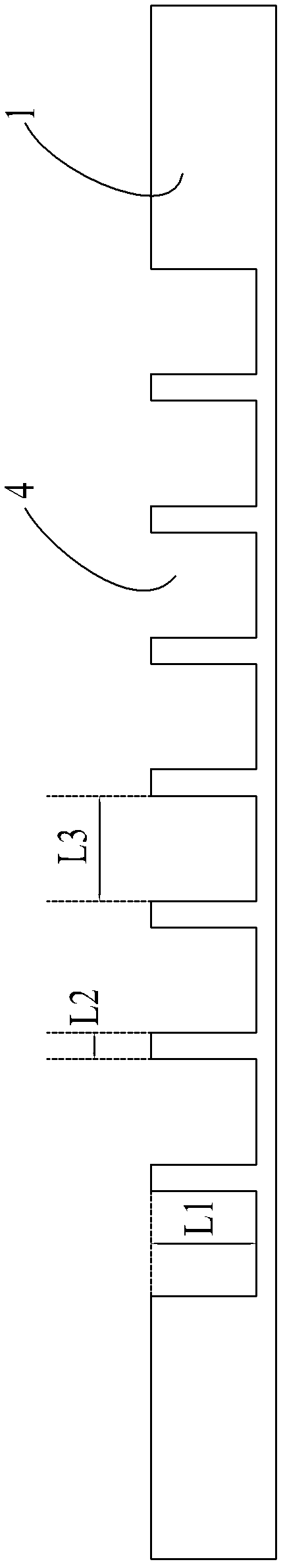

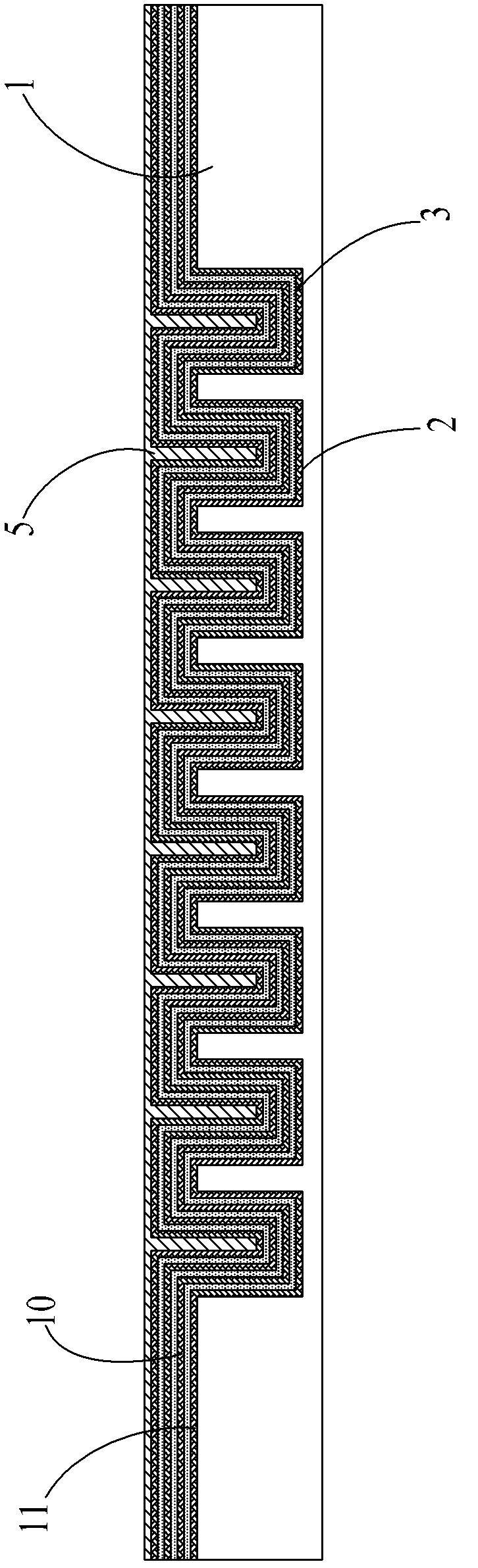

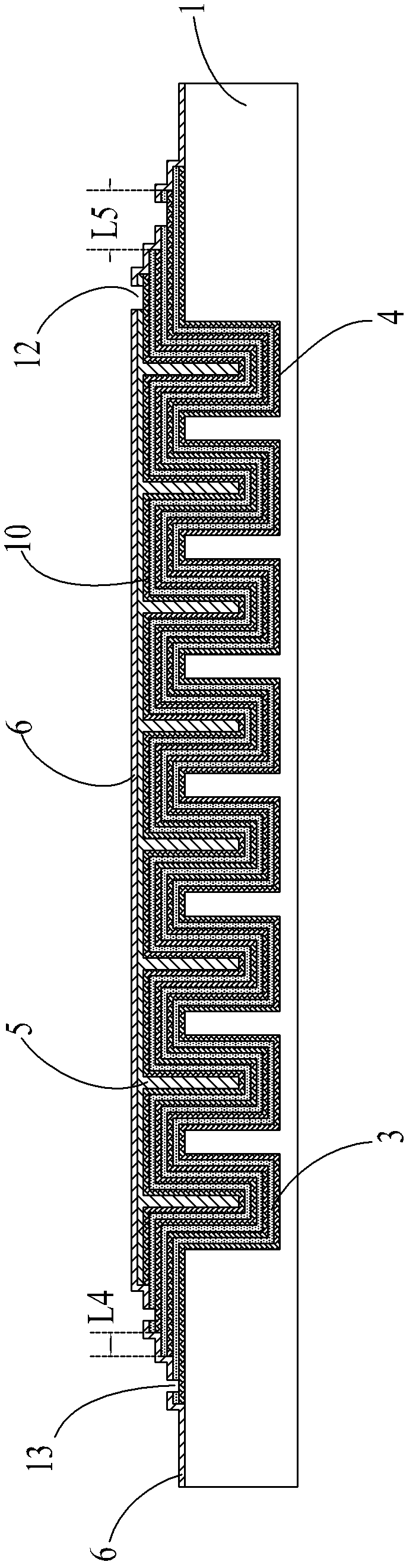

[0059] Such as Figure 1~Figure 5 Shown: this embodiment takes four local electrode layers 2 and three high-dielectric constant dielectric layers 3 as an example. That is, the local electrode layer 2 includes two odd-numbered local electrode layers 11 and two even-numbered local electrode layers 10, with odd local The electrode layer 11 is at the odd-numbered layer position above the substrate 1, and the even-numbered local electrode layer 10 is at the even-numbered layer position above the substrate 1, and is interleaved with the odd-numbered local electrode layer 11. The odd-numbered local electrode layer 11 and the even-numbered local electrode layer 10 The number of layers is the same; the odd-numbered interconnection electrodes 7 and even-numbered interconnection electrodes 8 corresponding to the interconnection electrode layer are alternately distributed around the substrate 1, and the odd-numbered interconnection electrodes 7 and the even-numbered interconnection electrodes...

Embodiment 2

[0075] Such as Figure 6~Figure 10 It is shown that the material types and sizes of the substrate 1, the microgrooves 4, the local electrode layer 2, the high dielectric constant dielectric layer 3, and the insulating dielectric layer 5 are consistent with those of the first embodiment. The first insulating protective layer 6 is SiO with a thickness of 2 μm 2 ; The difference is that the middle of the upper part of the substrate 1 is provided with a contact hole for the local electrode layer 2, and the lower part of the contact hole position has no microgrooves 4 structure, that is, the first odd-numbered contact hole 13 and the first even-numbered contact hole 12 are simultaneously located in the substrate 1 The upper periphery and the central area; finally, a second insulating protective layer 9 with a thickness of 2 μm is deposited on the top surface of the substrate 1 by PECVD, and the second insulating protective layer 9 is SiO 2 Or Si 3 N 4 , The electrode contact hole can ...

Embodiment 3

[0095] Such as Figure 11~Figure 16 Shown: in this embodiment, even-numbered interconnection electrodes 8 and odd-numbered interconnection electrodes 7 corresponding to the interconnection electrode layer are located in two layers, and even-numbered interconnection electrodes 8 and odd-numbered interconnection electrodes 7 are located at the same time on the upper side of the substrate 1 and correspondingly In the central area, the rest of this embodiment is consistent with the second embodiment.

[0096] Such as Figure 11 to Figure 16 As shown, the high-density capacitor with the above structure and its electrode lead form can be realized through the following process steps:

[0097] a. Provide substrate 1, and form microgrooves 4 on substrate 1, such as Picture 11 As shown; the microgrooves 4 can be processed by photolithography etching, photoelectrochemical etching, electrochemical etching, photolithography plating, self-assembly, selective liquid phase chemical deposition, etc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com