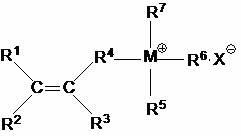

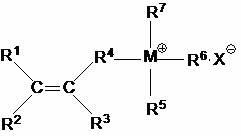

Preparation method of quaternary phosphonium cation starch microspheres

A cationic starch and quaternary phosphonium-type technology, which is applied in the field of preparation of quaternary phosphonium-type cationic starch microspheres, can solve the problems of few reports on the preparation and research of cationic starch microspheres, achieve reduced material costs, strong binding ability, Ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Measure 100 ml of toluene and 40 ml of castor oil, put them in a 250 ml three-necked bottle, add 0.8 g of Span80, heat to 50°C, stir evenly, and form an oil phase. Take another 6 grams of cornstarch, gelatinize with 50 ml of distilled water at 85°C for 30 minutes, and cool to room temperature. Add 1 gram of N,N'-methylenebisacrylamide, 2 grams of acrylamide, 3 grams of allyltrimethylammonium chloride, 1 gram of allyltriphenylphosphonium bromide and 0.1 gram of ammonium persulfate, stirred evenly to obtain the aqueous phase. Slowly add the water phase to the oil phase, control the stirring speed at 600 rpm, take samples every 2 minutes and observe under the microscope. After the liquid beads are evenly dispersed, slowly add a small amount of aqueous solution with 0.02 g of sodium bisulfite dissolved in advance. React for 3 hours. Then, filter, wash with ethyl acetate, and then wash repeatedly with acetone and ethanol. Vacuum drying at 50°C to obtain white powdery star...

Embodiment 2

[0031] Measure 120 ml of cyclohexane, place it in a 250 ml three-necked bottle, add 0.6 g of Span80 and 0.4 g of Tween60, heat to 50° C., stir evenly, and form an oil phase. Another 2.0 g of soluble corn starch was taken, gelatinized with 20 ml of distilled water at 80° C. for 30 minutes, and cooled to room temperature. Add 0.3 g of N,N'-methylenebisacrylamide, 2.0 g of acrylamide, 0.5 g of vinylbenzyltributylphosphonium chloride and 0.03 g of cerium ammonium nitrate to the starch paste under stirring, stir well, and wash with nitric acid Adjust to slightly acidic to obtain an aqueous phase. Slowly add the water phase to the oil phase, take samples every 2 minutes and observe under the microscope. After the liquid droplets are evenly dispersed, raise the temperature to 40°C and react for 4 hours. Then, let it stand, high-speed centrifugation, and separate the upper oil phase. The polymer phase in the lower layer was first cleaned with ethyl acetate, then washed repeatedly wi...

Embodiment 3

[0033]Measure 80 ml of cyclohexane and 20 ml of chloroform, put them in a 250 ml three-necked bottle, add 0.9 g of Span60 and 0.1 g of Tween60, heat to 50 ° C, stir evenly, and form an oil phase. Take another 2 grams of tapioca starch, gelatinize with 30 ml of distilled water at 85°C for 30 minutes, cool to room temperature, continue to add 0.4 g of N,N'-methylenebisacrylamide, 0.6 g of acrylamide, 0.5 g of vinylbenzyl Tributylammonium chloride, 1.5 g of vinylbenzyltributylphosphonium chloride and 0.2 g of sodium persulfate were stirred evenly to obtain an aqueous phase. Slowly add the water phase to the oil phase, control the stirring speed at 1500 rpm, take samples every 2 minutes and observe under the microscope until the liquid droplets are evenly dispersed, and then fill with nitrogen and deoxygenate for 15 minutes. Then the temperature was raised to 65° C., an aqueous solution in which 0.15 g of sodium bisulfite was dissolved in advance was added, and the mixture was rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com