Human serum albumin nano biomaterial and preparation method thereof

A technology of human serum albumin and nanofibers, applied in the direction of spinning solution preparation, single-component protein rayon, application, etc., to achieve the effect of simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

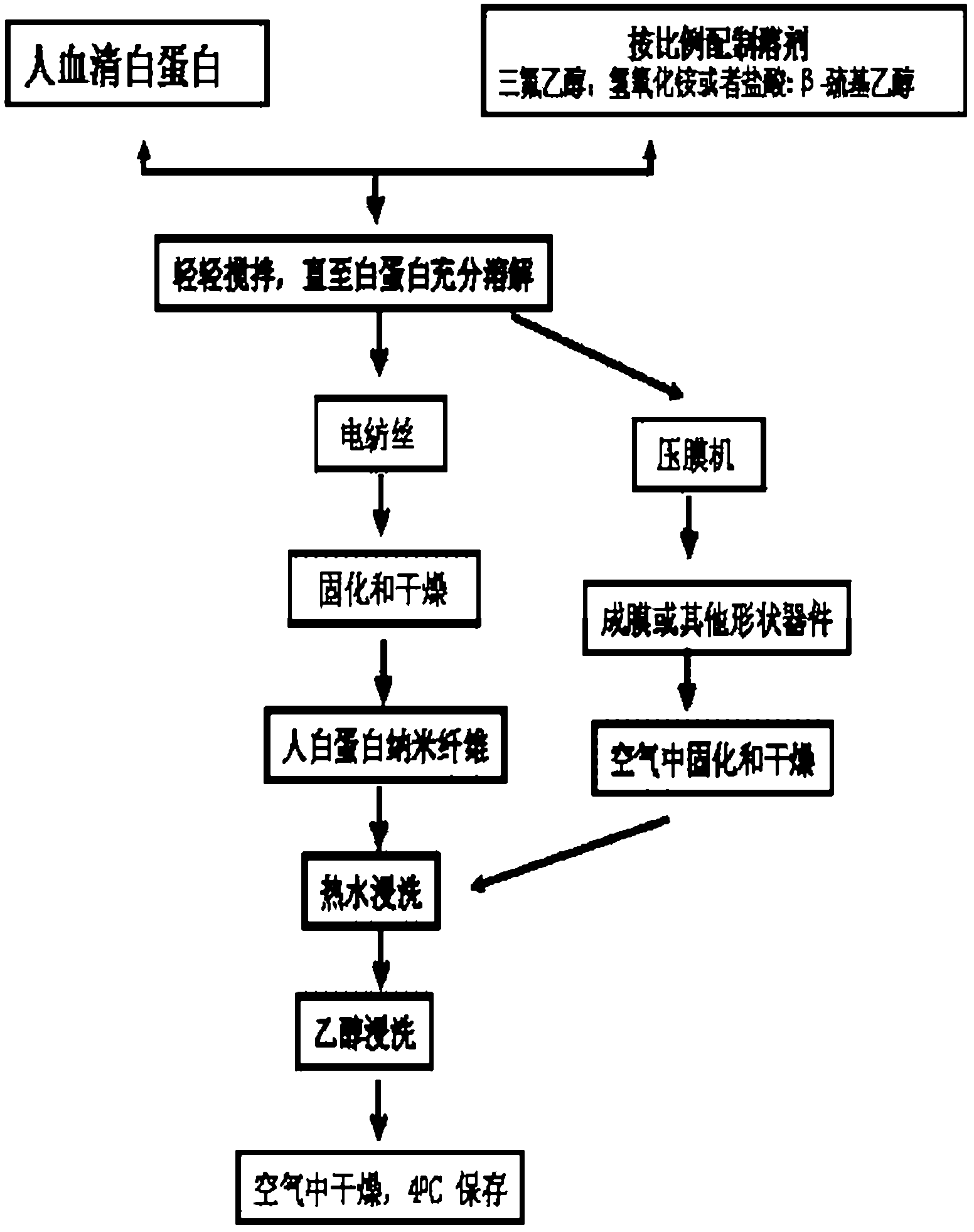

Method used

Image

Examples

Embodiment 1

[0045] Prepare a solution system for dissolving albumin: add 0.27ml of 0.1M ammonium hydroxide to 1.74ml of trifluoroethanol, then add 50ul of mercaptoethanol, stir to make it fully mixed. Weigh 0.3 g of recombinant human serum albumin (10%, w / v) and dissolve it in the above solution, stir gently with a magnetic bar for 30 minutes until the albumin is fully dissolved, and pump air with a vacuum pump for 30 minutes to eliminate the bubbles to obtain spinning solution.

[0046] The spinning solution is formed on a collector with a flow rate of 0.3ml per hour through the spinneret hole, an electric field intensity of 1.0KV / cm, a distance between the electrode and the rotating disk of 14cm, and a collector rotating disk edge speed of 8 m / s. After curing and drying for 24 hours in a glass drying dish (humidity 30%), human albumin nanofibers were obtained.

[0047] The albumin fibers were then soaked in deionized hot water at 37°C for 1 hour, then soaked in 35% ethanol prepared fro...

Embodiment 2

[0050]Albumin derived from human plasma (non-genetic recombination) was selected as the matrix material. Prepare a solution system for dissolving albumin: add 0.27ml of 0.1M ammonium hydroxide to 1.74ml of trifluoroethanol, then add 50ul of mercaptoethanol, stir to make it fully mixed. Weigh 0.3 g of recombinant human serum albumin (10%, w / v) and dissolve it in the above solution, stir gently with a magnetic bar for 30 minutes until the albumin is fully dissolved, and pump air with a vacuum pump for 30 minutes to eliminate the bubbles to obtain spinning solution.

[0051] The spinning solution is formed on a collector with a flow rate of 0.3ml per hour through the spinneret hole, an electric field intensity of 1.0KV / cm, a distance between the electrode and the rotating disk of 14cm, and an edge speed of the collector rotating disk of 8 m / s. After curing and drying for 24 hours in a glass drying dish (humidity 30%), human albumin nanofibers were obtained.

[0052] The albumin...

Embodiment 3

[0055] Prepare a solution system for dissolving albumin: add 0.16ml of 0.1M ammonium hydroxide to 1.85ml of trifluoroethanol, then add 50ul of mercaptoethanol, stir to make it fully mixed. Weigh 0.37 g of recombinant human serum albumin (12%, w / v) and dissolve it in the above solution, stir gently with a magnetic bar for 30 minutes until the albumin is fully dissolved, and pump air with a vacuum pump for 30 minutes to eliminate the bubbles to obtain spinning solution.

[0056] The spinning solution is formed on a collector with a flow rate of 0.3ml per hour through the spinneret hole, an electric field intensity of 1.0KV / cm, a distance between the electrode and the rotating disk of 14cm, and an edge speed of the collector rotating disk of 8 m / s. After curing and drying for 24 hours in a glass drying dish (humidity 30%), human albumin nanofibers were obtained.

[0057] The albumin fibers were then soaked in deionized hot water at 37°C for 1 hour, then soaked in 35% ethanol pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com