Method for preparing lithium adsorbent resin

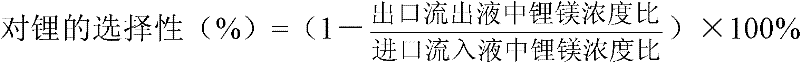

A lithium adsorption and resin technology, applied in the field of lithium adsorbent preparation, can solve the problems of difficult industrialized operation, poor selectivity effect, low lithium recovery rate, etc., and achieve the effects of improving application performance, long service life and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 15g manganese hydroxide powder, 10g Fe(OH) 3 Powder, 5g of titanium dioxide powder, 20g of lithium carbonate, (the molar ratio of lithium to metal is 1.67:1), ground evenly in a mortar, put it into a muffle furnace and roast at 600°C for 8h to obtain the ion sieve lithium adsorbent precursor 30g of the precursor, set aside; weigh 15g of polyacrylamide (molecular weight: 1 million to 5 million) powder, 125g of water, and 30g of the above-mentioned precursor, put it in a 500ml beaker and heat it to 60°C while stirring, and cool down to 30°C after the polyacrylamide dissolves. Add 5g of formaldehyde and stir evenly, then add 2g of citric acid, stir evenly to obtain a stable dispersed phase for later use. Measure 400ml of chlorobenzene and pour it into a 1000ml three-port reaction kettle, add 0.3g of Span 80, stir at 30°C to completely dissolve and form a continuous phase, adjust the stirring speed to 400rpm, and slowly pour the dispersed phase prepared above into a 1...

Embodiment 2

[0048] Weigh 50g of aluminum trichloride in a 400ml beaker, add 200ml of water, add 45g of NaOH under stirring, raise the temperature to 90°C for 3 hours to obtain a suspension; then add 100g of construction glue 108 (the composition is polyvinyl alcohol), 1g of hydroxyl Ethyl cellulose, after stirring evenly, add 2g of copper nitrate, after stirring evenly, obtain a stable dispersed phase, set aside. Measure 500ml of 300# liquid paraffin and pour it into a 1000ml three-port reaction kettle, add 1g of Tween-20, 3g of Span-65, stir to dissolve to form a continuous phase. Pour the above dispersed phase liquid into the liquid wax, adjust the stirring speed to disperse into spherical particles of 0.3-1.2mm, then add 10g of 6% boric acid solution dropwise, react at 35°C for 3h, heat up to 110°C for 20 hours Finish. Cool down, filter out the spherical particles, wash with ethanol, and then wash with water to remove the ethanol to obtain resin B.

[0049] Take 85g of spherical resi...

Embodiment 3

[0051] Weigh 80g Fe(NO 3 ) 3 Powder, 15g MnO 2 Powder, 5g Al(OH) 3 Powder, 22g of lithium carbonate, (the molar ratio of lithium to metal is 1.05:1), after mixing and grinding evenly, put it into a porcelain crucible, place it in a muffle furnace and roast at 550°C for 12h, let it cool to get 30g of lithium adsorbent precursor , set aside; weigh 40g polystyrene, 10g polymethyl acrylate, dissolve it with 180ml dichloroethane to make a viscous liquid, then add the above-mentioned precursor, stir evenly to make a dispersed phase for later use; add 500ml Saline with a specific gravity of 1.18, 1.5g of carboxymethyl cellulose, and 2g of gelatin are heated up to 50°C, stirred to fully dissolve to form a continuous phase, pour the dispersed phase prepared above into it, and adjust the stirring speed to form a continuous phase of 0.3-1.2 mm of spherical particles, heat up to 80°C for 15 hours, cool down, filter out the brine, dry the obtained spherical particles and place them in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com