Method for preparing high-efficiency ultraviolet-resistant titanium-dioxide nano granules

A titanium dioxide and nanoparticle technology is applied in the field of preparing high-efficiency anti-ultraviolet titanium dioxide nanoparticles, which can solve the problems of inability to improve sun protection factor and high sun protection factor, and achieve the effects of good anti-ultraviolet performance and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

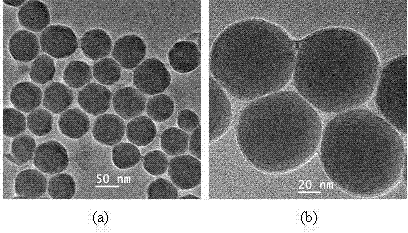

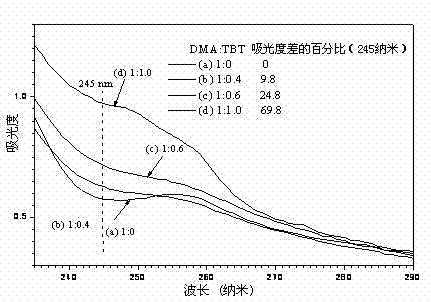

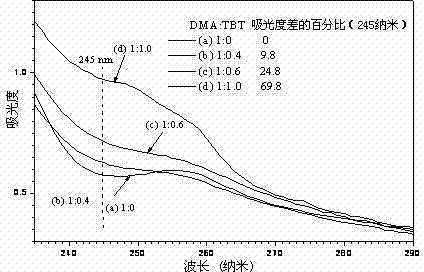

Image

Examples

Embodiment 1

[0034] 1) Amphiphilic triblock polymer PEO- b -PDMA- b -Synthesis of PS

[0035] Using 0.500g of brominated polyoxyethylene (PEO-Br) as a macroinitiator, 0.036g of catalyst cuprous bromide (CuBr), 0.044g of ligand PMDETA, and 1.580g of monomer dimethacrylate Add methylaminoethyl ester (DMA) and 4mL solvent into a 50mL round bottom flask for atom transfer radical polymerization (ATRP) at 30 o C. After 6 hours of reaction, 3.800g of styrene was diluted and added to the reaction flask to continue the reaction for 24 hours. The obtained polymer was rotary evaporated, passed through a silica gel column, concentrated, precipitated, pumped, and finally placed in a vacuum oven for 24 hours to obtain the block polymer PEO 43 - b -PDMA 40 - b -PS 140 .

[0036] 2) Polymers self-assemble to form micelles

[0037] The polymer was dissolved in tetrahydrofuran (THF), and a 20mg / mL solution was prepared, and methanol 60 times the volume of THF was added dropwise to the THF solution ...

Embodiment 2

[0044] 1) Amphiphilic triblock polymer PEO- b -PDMA- b -Synthesis of PS

[0045] 0.500g of macroinitiator PEO 43 -Br, 0.036g of catalyst cuprous bromide (CuBr), 0.044g of ligand PMDETA, 1.180g of monomer dimethylaminoethyl methacrylate (DMA) and 3mL of methanol solvent were added to a 50mL round bottom flask In, conduct atom transfer radical polymerization (ATRP), temperature 30 o C. After 6 hours of reaction, 2.800 g of styrene was dissolved in 3 mL of p-xylene, and the reaction was continued for 24 hours. The obtained polymer was rotary evaporated, passed through a silica gel column, concentrated, precipitated, pumped, and finally placed in a vacuum oven for 24 hours to obtain the block polymer PEO 43 - b -PDMA 30 - b -PS 100 .

[0046] 2) Polymers self-assemble to form micelles

[0047] Dissolve the polymer in dichloromethane, prepare a 30mg / mL solution, add dropwise ethanol 80 times the volume of dichloromethane to the above solution at a rate of 10d / min under st...

Embodiment 3

[0052] 1) Amphiphilic triblock polymer PEO- b -PDMA- b -Synthesis of PS

[0053] With 1.000g of brominated polyoxyethylene (PEO-Br) as macromolecular initiator, 0.072g of catalytic

[0054] The agent cuprous bromide (CuBr), 0.088g of the ligand PMDETA, 3.160g of the monomer dimethylaminoethyl methacrylate (DMA) and 5mL of methanol solvent were added to a 50mL round bottom flask for free atom transfer radical polymerization (ATRP), temperature 30 o C. After 6 hours of reaction, dissolve 3.300g of styrene in 6mL of p-xylene, add it into the reaction flask and continue to react for 24 hours. After post-treatment, the block polymer PEO is obtained 43 - b -PDMA 40 - b -PS 120 .

[0055] 2) Polymers self-assemble to form micelles

[0056] Dissolve the polymer in dichloromethane, prepare a 20 mg / mL solution, add ethanol 80 times the volume of dichloromethane dropwise to the THF solution at a rate of 10 d / min under stirring, and obtain a milky white solution after stirring f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com