SiC honeycomb ceramics material and preparation method thereof

A honeycomb ceramic and honeycomb-shaped technology, which is applied in the field of SiC honeycomb ceramic material and its preparation, can solve the problems of low strength, difficulty in mold manufacturing, easy deformation during sintering, etc., and achieve the effect of good strength and controllable honeycomb pore shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

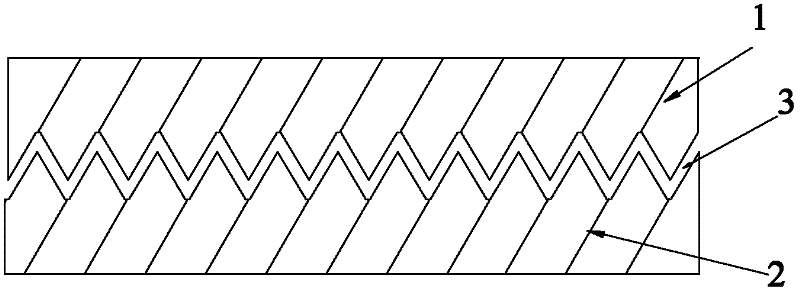

[0037] The preparation method of the honeycomb ceramic material of the present invention has a simple process and mainly includes raw material preparation, molding of a molding unit, assembly, pyrolysis and firing processes.

[0038] The preparation method uses solid particle powder and high-molecular materials with high carbon yield as raw materials, and is molded to prepare a single-layer honeycomb unit combination, followed by pyrolysis and sintering. The specific preparation process is as follows:

[0039] (1) Mix solid particle powder (silicon carbide powder, silicon powder or both mixed powder), polymer material, curing agent and organic solvent in a certain proportion, ball mill after mechanical stirring, and filter to obtain slurry. The solute of the slurry solution is 5-80% of the total mass; afterward, a certain amount of organic solvent in the slurry is removed by air-drying, so that the mass content of the organic solvent after air-drying is between 10-15%.

[0040] ...

Embodiment 1

[0050] Co-dissolve silicon carbide powder with an average particle size of 5 μm, aminophenol-formaldehyde resin, and p-toluenesulfonic acid with a mass ratio of 60%: 35%: 5%, respectively, in absolute ethanol, ball mill after mechanical stirring, and filter to obtain a slurry. The solute in the slurry solution is 80% of the total mass; air-dried to remove a certain amount of ethanol in the slurry, so that the mass content of the organic solvent after air-drying is 10%. Coat this raw material evenly on the polyvinyl alcohol non-woven fabric, and then spread it on one side of the split mold with triangular slots heated to 120°C, close the mold and press to the limit, and the limit between the molds Ensure that the gap is 0.3mm, keep warm for 1 minute and then solidify. Open the mold to get a corrugated single-layer honeycomb unit with triangular grooves. After preparing several units in this way, stack these units with slurry and cure. After solidification, the honeycomb ceramic...

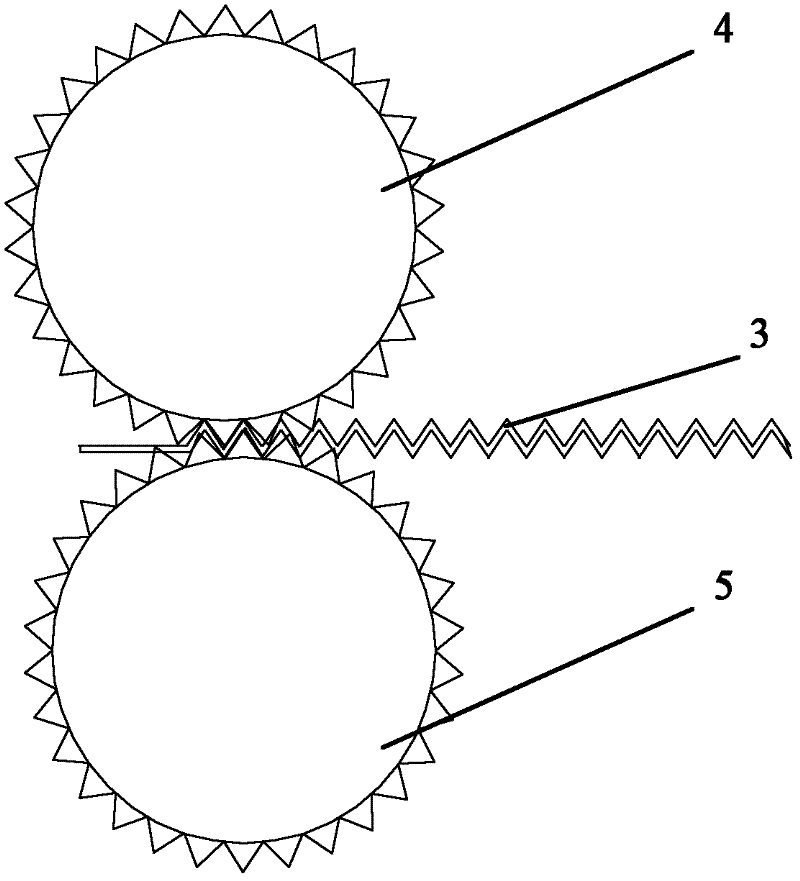

Embodiment 2

[0054] Co-dissolve silicon carbide powder with an average particle size of 5 μm and silicon powder with an average particle size of 3 μm, aminophenol-formaldehyde resin, and p-toluenesulfonic acid with a mass ratio of 50%: 10%: 35%: 5% in absolute ethanol, and mechanically stir After ball milling and filtering, a slurry is obtained. The solute in the slurry solution is 75% by mass, and air-dried to remove a certain amount of ethanol in the slurry, so that the mass content of the organic solvent after air-drying is 15%. Coat this raw material evenly on the polyvinyl alcohol non-woven fabric, and then squeeze it through the wavy toothed pair of rollers heated to 150°C. The gap between the upper and lower rollers is 0.3mm, and the rolling speed is 1m / After 1 min, a corrugated single-layer honeycomb unit with wavy grooves is obtained. After preparing several units in this way, these units are stacked and bonded with slurry. After solidification, the honeycomb ceramic prefabricated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com