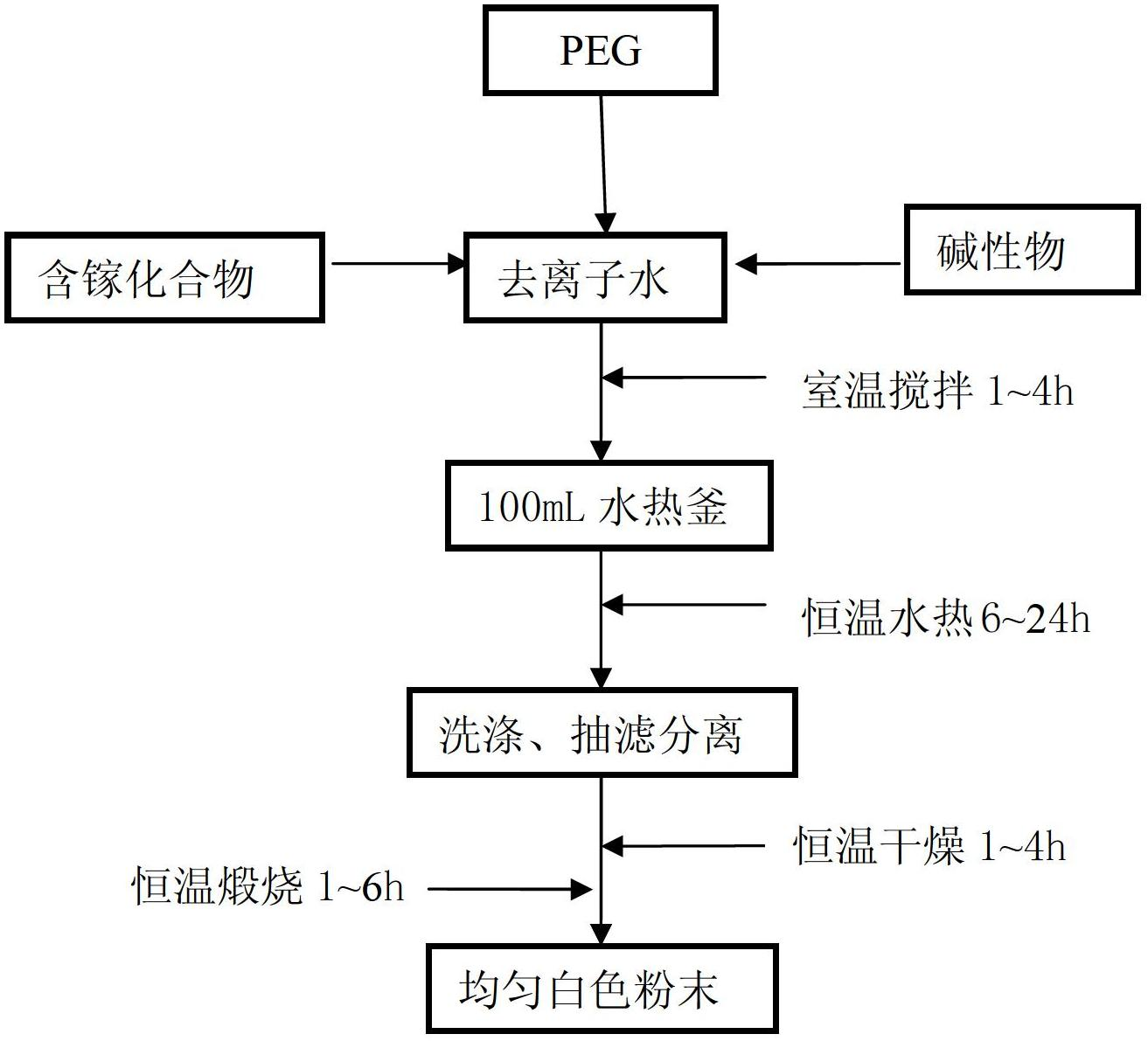

Method for preparing mesoporous beta-Ga2O3 nanorod photocatalyst by using PEG (polyethylene glycol) as template

A photocatalyst, -ga2o3 technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems affecting photocatalytic performance and application, irregular structure, large grain size, etc. Achieving good application prospects, low cost and good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 1.6g of gallium nitrate and 1.7g of sodium hydroxide into a 100mL autoclave, then add 5mL of PEG200 and 35mL of deionized water, stir at room temperature for 1 hour until completely dissolved, then hydrothermally react at 100°C 6 hours.

[0031] (2) After cooling, separate by suction filtration, wash with deionized water for 3 times, then wash with absolute ethanol for 4 times, dry at 100°C for 1 hour, and grind to obtain white powder GaOOH.

[0032] (3) Transfer the above GaOOH to a muffle furnace and calcine at 500°C for 1 hour to obtain uniform and stable mesoporous β-Ga 2 o 3 Nanorod photocatalysts.

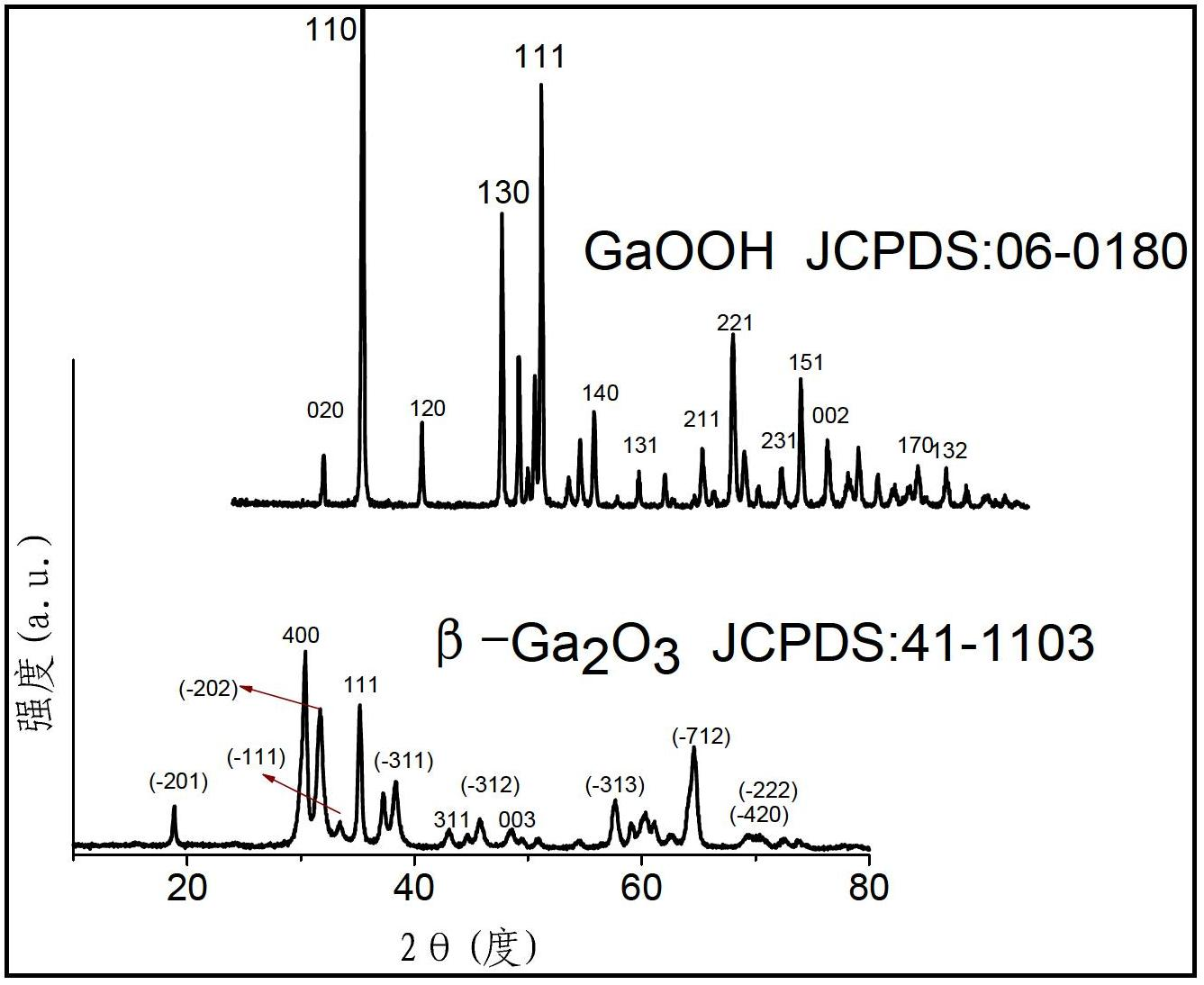

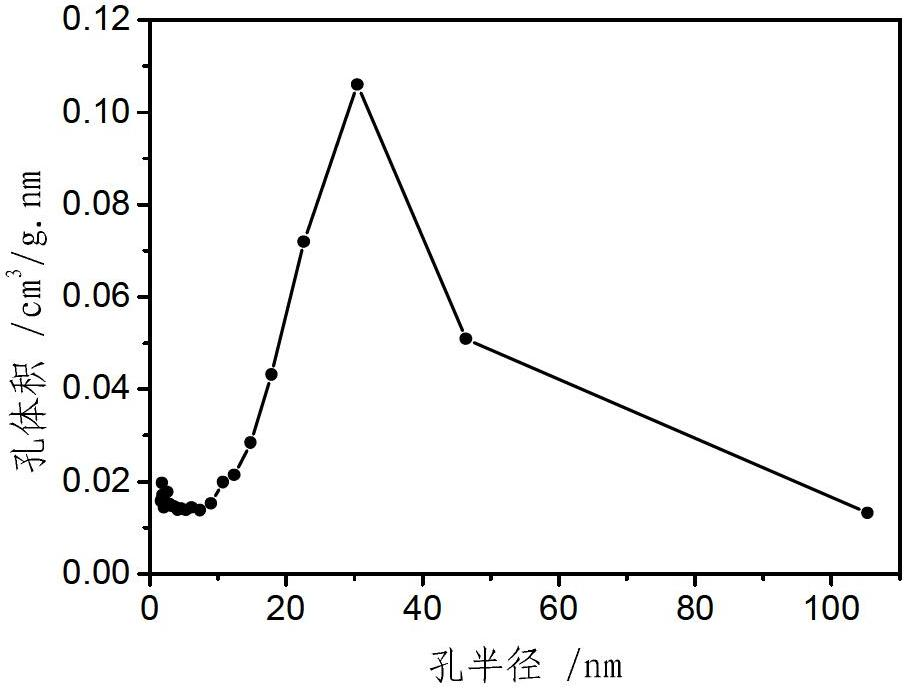

[0033] After XRD characterization, the precursor GaOOH obtained after hydrothermal treatment is orthorhombic (JCPDS: 06-0180), and the β-GaOOH obtained after calcination 2 o 3 It is monoclinic (JCPDS: 41-1103), see figure 2 . After BET characterization, the prepared β-Ga 2 o 3 The average pore size is 17.30nm, which belongs to mesoporous material, se...

Embodiment 2

[0035] (1) Weigh 1.6g of gallium nitrate and 2.64g of urea into a 100mL autoclave, then add 20mL of PEG200 and 45mL of deionized water, stir at room temperature for 2 hours until completely dissolved, and conduct a hydrothermal reaction at 140°C for 6 hours.

[0036] (2) After cooling, separate by suction filtration, wash with deionized water for 4 times, then wash with absolute ethanol for 5 times, dry at 200°C for 2 hours, and grind to obtain white powder GaOOH.

[0037] (3) Transfer the above GaOOH to a muffle furnace and calcinate at 800°C for 2 hours to obtain uniform and stable mesoporous β-Ga 2 o 3 Nanorod photocatalysts.

[0038] Characterized by TEM and SEM, the prepared β-Ga 2 o 3 It is a rod-like structure with an average diameter of 200nm and a length distribution of 1.00~1.05μm. There are many nanoscale pores on the surface of the catalyst, see Figure 5 with Image 6 ; Prepared β-Ga 2 o 3 The specific surface area of the nanorods is 29.00m 2 / g, with an a...

Embodiment 3

[0040] (1) Weigh 0.71g of gallium chloride and 2.64g of urea into a 100mL autoclave, then add 20mL of PEG1000 and 45mL of deionized water, stir at room temperature for 3 hours until completely dissolved, and then hydrothermally react at 200°C for 12 hours .

[0041] (2) After cooling, separate by suction filtration, wash 5 times with deionized water, then wash 3 times with absolute ethanol, dry at 150°C for 3 hours, and grind to obtain white powder GaOOH.

[0042] (3) Transfer the above GaOOH to a muffle furnace and calcine at 800°C for 5 hours to obtain uniform and stable mesoporous β-Ga 2 o 3 Nano stave.

[0043] The prepared β-Ga 2 o 3 The specific surface area of the nanorods is 20.62 m 2 / g, the length distribution is 1.00~1.10μm, the average diameter is 260nm, and the average pore diameter is 50nm, which belongs to mesoporous material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com