Preparation method of composite material used in underground water nitrogen pollution remediation technology

A pollution remediation and composite material technology, applied in the field of groundwater pollution remediation, can solve the problems of high investment, poor selectivity, nitrate pollution, etc., and achieve the effect of improving denitrification reaction efficiency, reducing removal steps, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope described in the examples.

[0014] 1) Preparation of spherical particles.

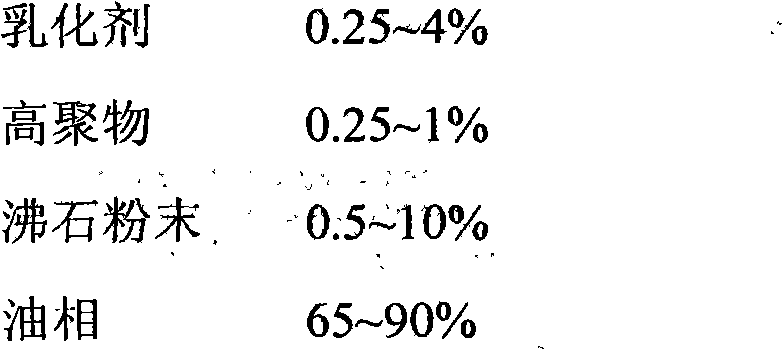

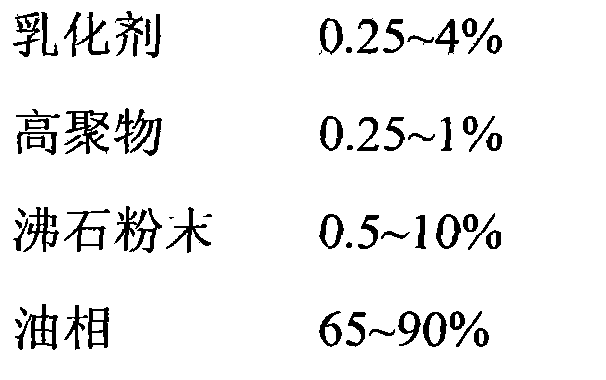

[0015] Main component quality: 2 parts of sorbitan fatty acid ester, 9 parts of chitosan solution (containing 0.5 part of chitosan), 4 parts of clinoptilolite powder, 85 parts of edible oil.

[0016] First drop the sorbitan fatty acid ester into the edible oil by the inverse emulsion method (water in oil), stir for about ten minutes, add the clinoptilolite powder into the chitosan solution, stir, and put the fully mixed solution in the Drop into edible oil under continuous stirring, continue stirring for 30 minutes, rotate at a speed of 400 r / min, and filter with a vacuum pump, wash the obtained solid powder with absolute ethanol, and then filter with suction to obtain spherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com