Preparation method for intermediate base-cycloalkyl crude oil emulsion de-emulsifier and product thereof

A technology of naphthenic crude oil and demulsifier, which is applied in the direction of dehydration/demulsification by chemical methods, can solve the problems of high demulsification temperature, slow demulsification speed and poor adaptability, and achieves simple synthesis process, mild operating conditions, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

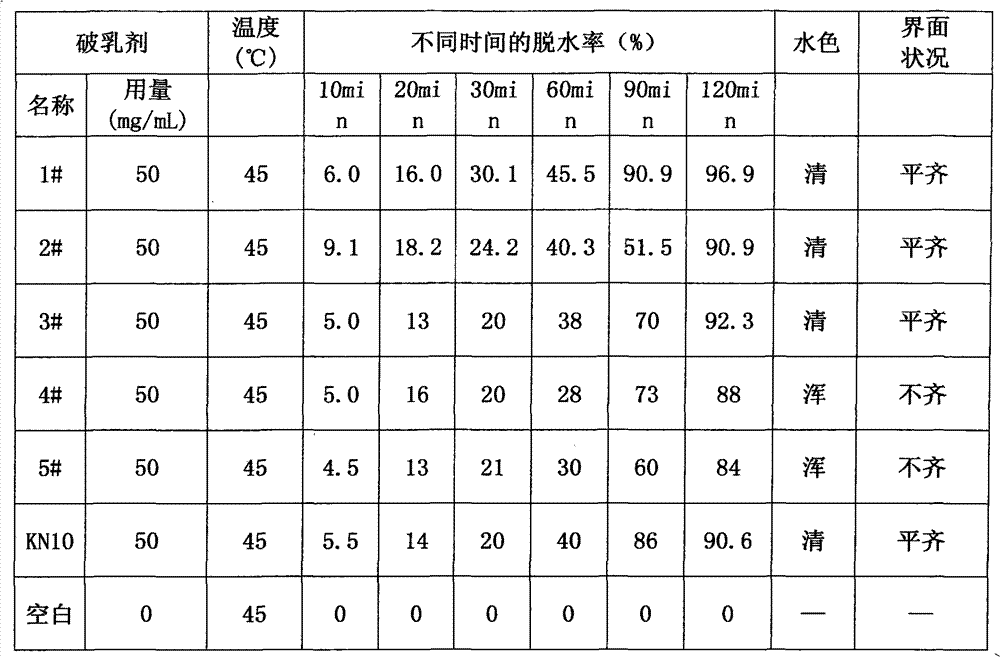

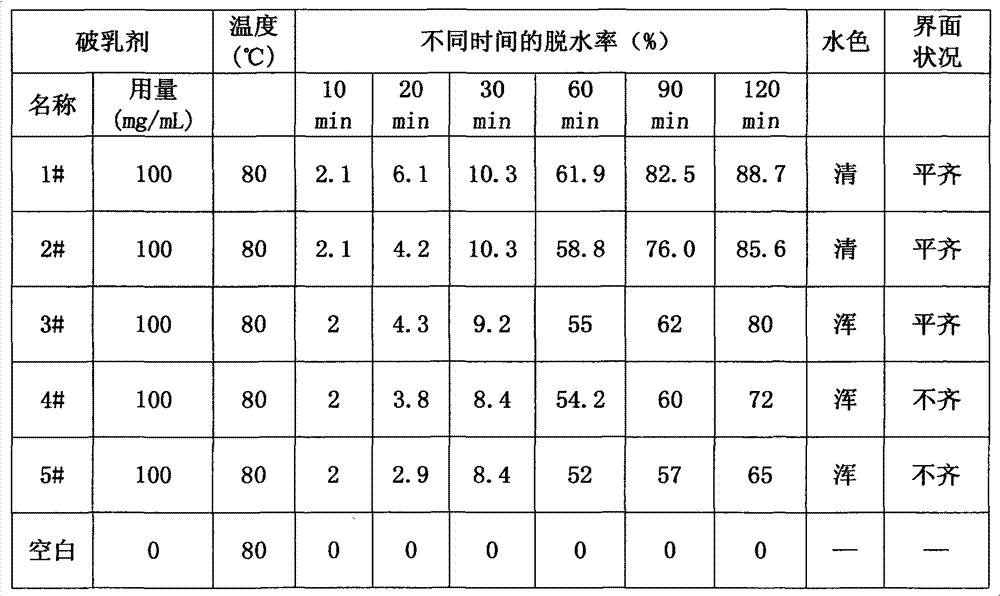

Embodiment 1

[0022] Add 50kg of tetraethylenepentamine to the autoclave, 1.5kg of potassium hydroxide catalyst and control the temperature of the autoclave at 110-120°C to control the pressure of the autoclave to 0.2-0.3MPa, inject 800kg of ethylene oxide into the autoclave for polymerization reaction to obtain oil head A. Take 100kg of synthetic oil head A and put it into the reaction kettle, heat it to 134-150°C, add 2.5kg of potassium hydroxide catalyst, inject 660kg of propylene oxide into the polymerization reaction with nitrogen pressure, and inject ethylene oxide with nitrogen pressure at 110-128°C 200kg of alkanes were polymerized to obtain block polyether macromolecular compounds. After the synthetic block polyether is neutralized, bleached, filtered, etc., take 550kg and put it into the mixing tank, add 220kg of methanol, 200kg of water, 5kg of synergist butyl cellosolve, and stir for 1 to 2 hours to obtain the demulsifier The product number is 1# demulsifier.

Embodiment 2

[0024] Add 120kg of pentaethylenehexamine to the autoclave, 2.0kg of catalyst is a mixture of potassium hydroxide and calcium hydroxide in a 2:1 weight ratio, heat up to 105-125°C, adjust the pressure range to 0.1-0.32MPa, use nitrogen pressure Add 800kg of ethylene oxide to the polymerization reaction to obtain the oil head A. Take 150kg of synthetic oil head A and put it into the reaction kettle, heat it to 110-145°C, add 2.0kg of potassium hydroxide catalyst, press nitrogen into 800kg of propylene oxide at 145°C for polymerization reaction, and press nitrogen into it at 115-130°C 550 kg of ethylene oxide was polymerized to obtain a block polyether macromolecular compound. After the synthetic block polyether is neutralized, bleached and filtered, take 700kg, 300kg of water, and 350kg of methanol into the reaction kettle, add 5kg of synergist hydrochloric acid, stir well before adding, and heat up to 60-80°C , and react for 1 to 1.5 hours to complete the reaction to obtain t...

Embodiment 3

[0026] Add 120kg of ethylenediamine to the autoclave, mix 1.5kg of catalyst with calcium hydroxide and sodium hydroxide in a weight ratio of 1:2, raise the temperature to 105-125°C, adjust the pressure range to 0.15-0.25MPa, and press nitrogen into the ring Oxyethane 900kg, polymerization obtains oil head A. Take 100kg of synthetic oil head A and put it into the reaction kettle, heat it to 128-146°C, add 2.5kg of sodium hydroxide catalyst, inject 720kg of propylene oxide with nitrogen pressure at 130-145°C, and use nitrogen pressure at 120-130°C Add 550 kg of ethylene oxide, and polymerize to obtain a block polyether macromolecular compound. After the synthetic block polyether is neutralized, bleached and filtered, 800kg, 310kg of water and 400kg of ethanol are put into the reaction kettle, and 6kg of synergist formic acid is added, stirred and heated at 40-60°C for 1-1.5 hours to complete. Promptly obtain the demulsifier product, numbered as 3# demulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com