Amino functionalized superparamagnetism carbon nanosphere and preparation method thereof

An amino-functionalized, superparamagnetic technology, which is applied in the preparation of microspheres, nanotechnology for materials and surface science, nanotechnology, etc. The effect of wide practicability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

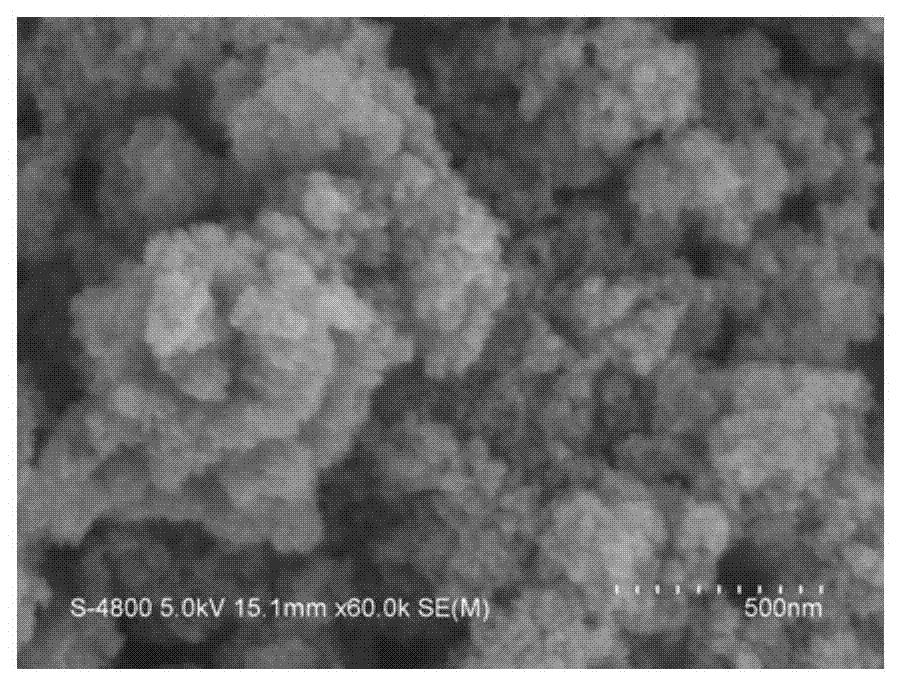

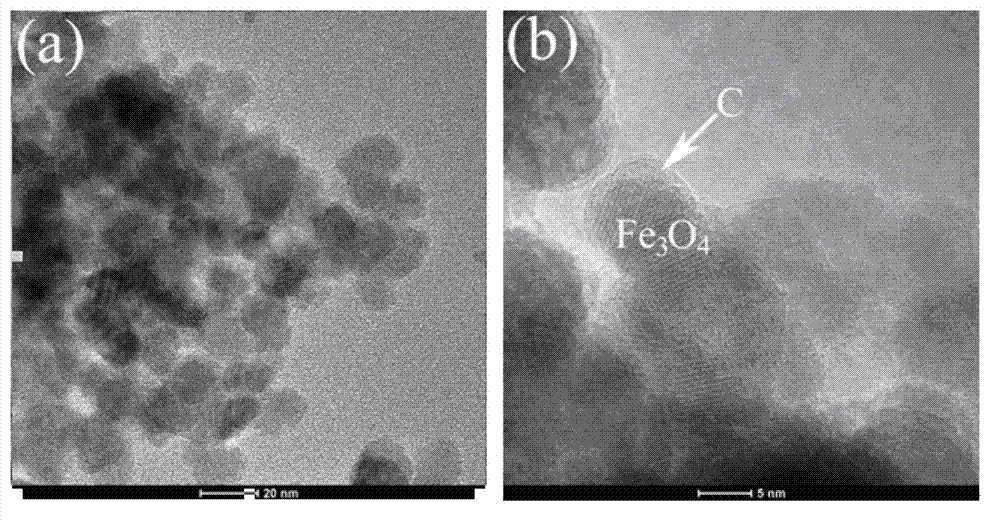

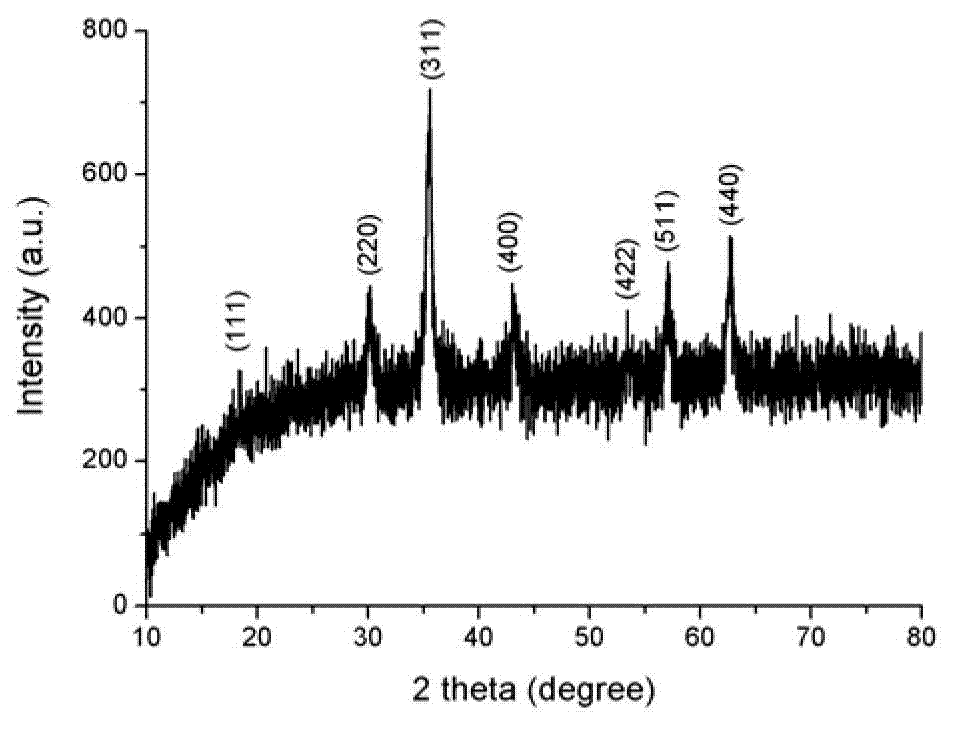

[0033] Weigh 706.3 mg iron acetylacetonate and add it to 20 mL polyethylene glycol 200, sonicate for 5 min to obtain 0.1 molL -1 Iron acetylacetonate solution; Weigh 360.0 mg of glucose and add it to the above iron acetylacetonate solution, sonicate for 5 min to obtain a mixed solution; transfer the above mixed solution to an autoclave, add 1 mL of ammonia water (NH 3 percentage content, 28%), tighten the autoclave, and react at 240°C for 24 h; after the reaction, cool down to room temperature naturally, and the obtained precipitate becomes black powder after magnetic separation, washing, and drying. The product was characterized by scanning electron microscopy, which confirmed that the diameter of the obtained aminated superparamagnetic carbon nanospheres was 10-30 nm; by X-ray diffraction, it was confirmed that the product was carbon-coated ferric oxide; by high-resolution transmission electron microscopy Characterization, confirmed that the inner core of magnetic carbon nan...

Embodiment 2

[0039] Weigh 372.1 mg ferrocene into 20 mL polyethylene glycol 200, sonicate for 5 min to obtain 0.1 molL -1 ferrocene solution; weigh 684.6 mg sucrose and add it to the above ferrocene solution, and ultrasonicate for 5 min to obtain a mixed solution; transfer the above mixed solution to an autoclave, add 1 mL of ammonia water (NH 3 percentage content, 28%), screw the autoclave tightly, and react at 240°C for 24 h. All the other conditions are the same as in Example 1, and the superparamagnetic carbon nanomaterial of amino functionalization and core-shell structure is obtained, and the mass percentage of carbon in the product is 94%, and the specific surface area of the product is 50.0 m 2 / g.

Embodiment 3

[0041] Weigh 706.3 mg of iron acetylacetonate into 20 mL of polyethylene glycol 200, sonicate for 5 min to obtain 0.1 molL -1 Iron acetylacetonate solution; weigh 684.6 mg sucrose and add it to the above iron acetylacetonate solution, and ultrasonicate for 5 min to obtain a mixed solution; transfer the above mixed solution to an autoclave, add 1 mL of ammonia water (NH 3 percentage content, 28%), screw the autoclave tightly, and react at 240°C for 24 h. The rest of the conditions are the same as in Example 1, and the superparamagnetic carbon nanomaterial with amino functionalization and core-shell structure is obtained, and the mass percentage of carbon in the product is 39.1%, and the specific surface area of the product is 77.8 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com