Method and device for recovery coupling of biological sulfur and carbon dioxide for producing biogas

A bio-natural gas and bio-desulfurization technology, applied in chemical instruments and methods, inorganic chemistry, gas fuel, etc., can solve the problems of restricting efficiency, hydrogen sulfide and carbon dioxide that have not been solved, and achieve energy saving, safety, and realization Selective absorption and high recovery of total sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

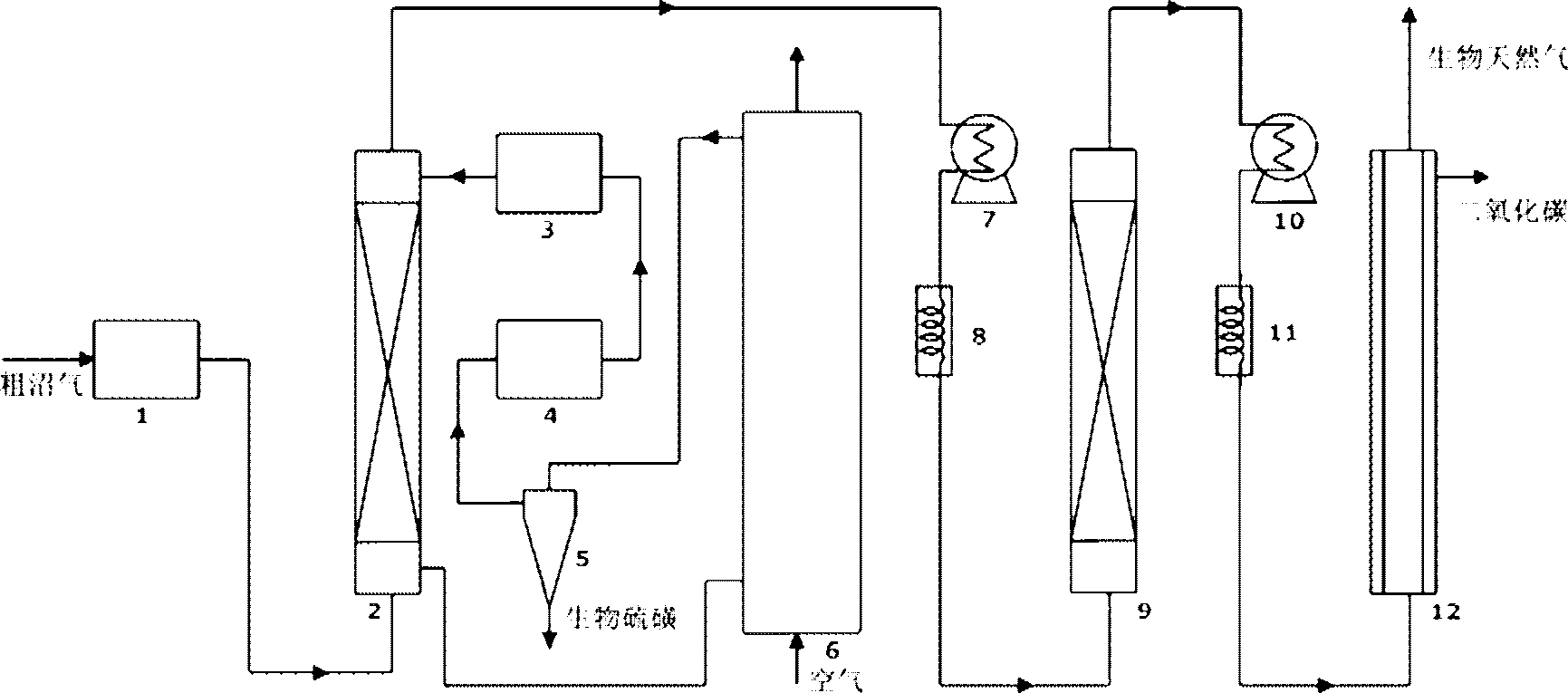

[0048] Embodiment 1 methane / carbon dioxide / hydrogen sulfide mixed gas treatment

[0049] Mixed gas: Under standard conditions, methane, carbon dioxide, and hydrogen sulfide are mixed in a volume ratio of 60:37:3, simulating the composition of biogas, and the processing capacity is 0.01Nm 3 / d.

[0050] The mixed gas enters the hydrogen sulfide absorption tower at a space velocity of 2m / S and a pressure of 0.2 Mpa, the contact time is 0.2±0.1s, Na 2 CO 3 / NaHCO 3 The pH value of the absorption liquid is 8.0, and the liquid-gas ratio is 3L / m 3 .

[0051] The rich liquid containing sulfide in the absorption tower enters the biological desulfurization reactor. Under the condition of ORP=-150mV±10, the sulfide is converted into elemental sulfur by sulfur-oxidizing bacteria. Elemental sulfur flows out with the effluent of the biological desulfurization reactor, and is collected by settling in the sedimentation tank.

[0052] The desulfurized raw gas is pressurized to 1.0Mpa b...

Embodiment 2

[0058] Example 2 Biogas production by anaerobic digestion of corn stalks

[0059] Corn stalks and cow dung were mixed in a ratio of 1:5 for anaerobic fermentation to produce biogas.

[0060] Main components of biogas: methane 48.9-57.1%, carbon dioxide 32.1-36.3%, hydrogen sulfide 0.1-0.2%. The gas production rate is 1.6-2.1Nm 3 / d.

[0061] After the biogas is dedusted, it enters the hydrogen sulfide absorption tower at a space velocity of 4m / S and a pressure of 0.2Mpa. The contact time is 0.4±0.1s, and the Na 2 CO 3 / NaHCO 3 The pH value of the absorption liquid is 7.0-8.0, and the liquid-gas ratio is 2-3L / m 3 .

[0062] The rich liquid containing sulfide in the absorption tower enters the biological desulfurization reactor. Under the condition of ORP=-150mV±10, the sulfide is converted into elemental sulfur by sulfur-oxidizing bacteria. Elemental sulfur flows out with the effluent of the biological desulfurization reactor, and is collected by settling in the sedimen...

Embodiment 3

[0069] Example 3 High hydrogen sulfide biogas produced by anaerobic treatment of high sulfate-containing wastewater of straw pretreated with dilute acid

[0070] Methane 40.2-44.3%, carbon dioxide 34.1-38.3%, hydrogen sulfide 2.2-2.7%. The gas production rate is 0.3-0.5Nm 3 / d.

[0071] After the biogas is dedusted, it enters the hydrogen sulfide absorption tower at a space velocity of 2m / S and a pressure of 0.2Mpa. The contact time is 0.4±0.1s, and the Na 2 CO 3 / NaHCO 3 The pH value of the absorption liquid is 7.5-8.0, and the liquid-gas ratio is 3-4L / m 3 .

[0072] The rich liquid containing sulfide in the absorption tower enters the biological desulfurization reactor. Under the condition of ORP=-150mV±10, the sulfide is converted into elemental sulfur by sulfur-oxidizing bacteria. Elemental sulfur flows out with the effluent of the biological desulfurization reactor, and is collected by settling in the sedimentation tank.

[0073] The desulfurized raw gas is pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com