Mo-C-N-Si-Nb gradient coating material and preparation method thereof

A mo-c-n-si-nb, gradient coating technology, applied in coating, metal material coating process, solid-state diffusion coating, etc. Short service life and other problems, to achieve the effect of improving high temperature oxidation resistance, improving high temperature strength, and accelerating thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

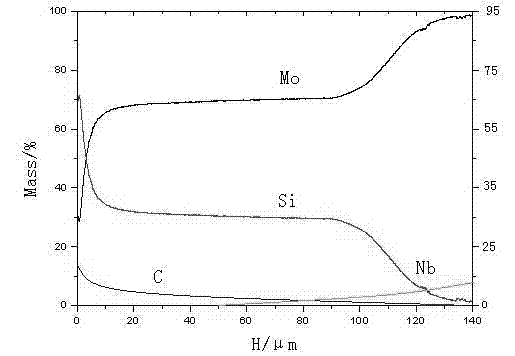

[0030] Example 1: The Mo-C-N-Si-Nb gradient coating material adopts the following preparation method.

[0031] Put the Mo-3Nb alloy plate (50mm×20mm×3mm) into the WZST-20 series double-chamber vacuum carburizing and quenching furnace, carry out carburizing at 800 °C for 60 minutes, and take it out after oil quenching and air cooling to obtain Mo-3Nb-1.7C Alloy (mass percentage), the penetration depth is 0.64-0.69 mm. Take 100g of block polycrystalline silicon with a purity of 7N and put it into a corundum dry pot, put it in an argon-protected high-temperature electric furnace and raise the temperature to 1500°C, and keep the temperature for 60 minutes; put the Mo-3Nb-1.7C alloy plate (50mm×20mm×3mm) into the In the molten Si solution, after hot-dip silicon infiltration at a temperature of 1500°C for 20 minutes, the alloy substrate is slowly taken out of the hot-dip plating solution, and after staying in the temperature range of the electric furnace temperature ≤ 500°C (close t...

Embodiment 2

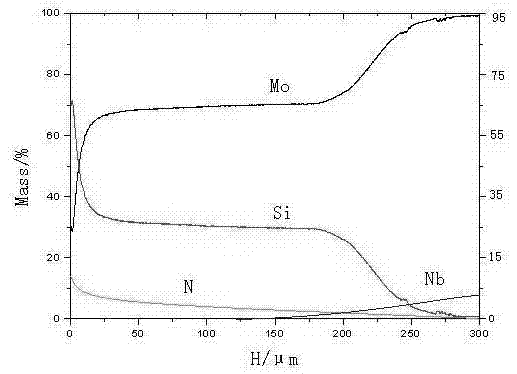

[0032] Example 2: The Mo-C-N-Si-Nb gradient coating material adopts the following preparation method.

[0033] Put the Mo-3Nb alloy plate (50mm×20mm×3mm) into the WZST-20 series double-chamber vacuum carburizing and quenching furnace, carry out nitriding at 900 °C for 120 minutes, and take it out after oil quenching and air cooling to obtain Mo-3Nb-0.8N Alloy (mass percentage), the penetration depth is 0.97-1.08 mm. Take 100g of block polysilicon with a purity of 7N and put it into a corundum dry pot, put it into a high-temperature electric furnace protected by argon to raise the temperature to 1550°C, and keep the temperature constant for 30min; put the Mo-3Nb-0.8N alloy plate (50mm×20mm×3mm) into the In the molten Si solution, after hot-dip silicon infiltration at a temperature of 1550°C for 40 minutes, the alloy substrate is slowly taken out of the hot-dip plating solution, and after staying in the temperature range of the electric furnace temperature ≤ 500°C (close to the ...

Embodiment 3

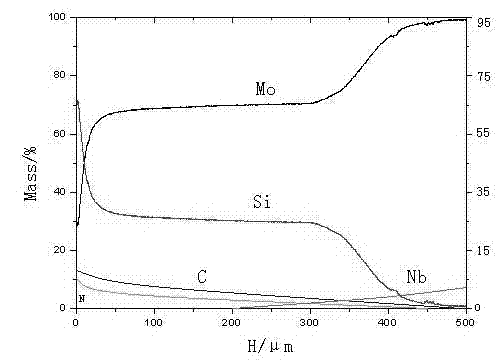

[0034] Example 3: The Mo-C-N-Si-Nb gradient coating material adopts the following preparation method.

[0035] Put the Mo-3Nb alloy plate (50mm×20mm×3mm) into the WZST-20 series double-chamber vacuum carburizing and quenching furnace, carry out carbonitriding at 1000°C for 180min, and take it out after oil quenching and air cooling to obtain Mo-3Nb- 3.4C-1.0N alloy (mass percentage), the penetration depth is 1.42-1.53 mm. Take 100g of block polysilicon with a purity of 7N and put it into a corundum dry pot, put it into an argon-protected high-temperature electric furnace and raise the temperature to 1450°C, and keep the temperature for 20min; ) into the molten Si solution, after hot-dip silicon infiltration at a temperature of 1450°C for 60 minutes, slowly take the alloy matrix out of the hot-dip plating solution, and stay in the temperature range of the electric furnace temperature ≤ 500°C (close to the furnace mouth) After 15 minutes, the Ar gas with a flow rate of 8 L / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com