Completely-crystallized multiferroic film without producing impure phase and preparation method thereof

A multiferroic and complete technology, used in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of inability to prepare complete crystals and no impurity phase, comprehensive performance decline, poor ferromagnetic performance, etc. Achieve low cost, improve ferroelectricity and ferromagnetism, and facilitate industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

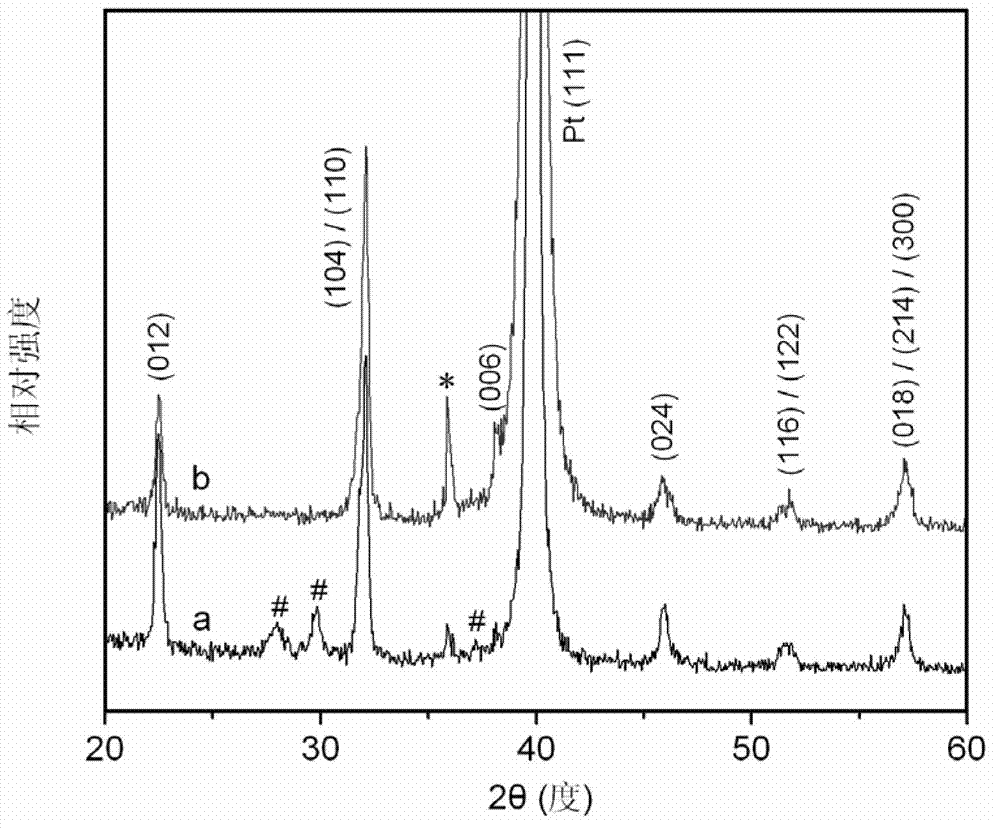

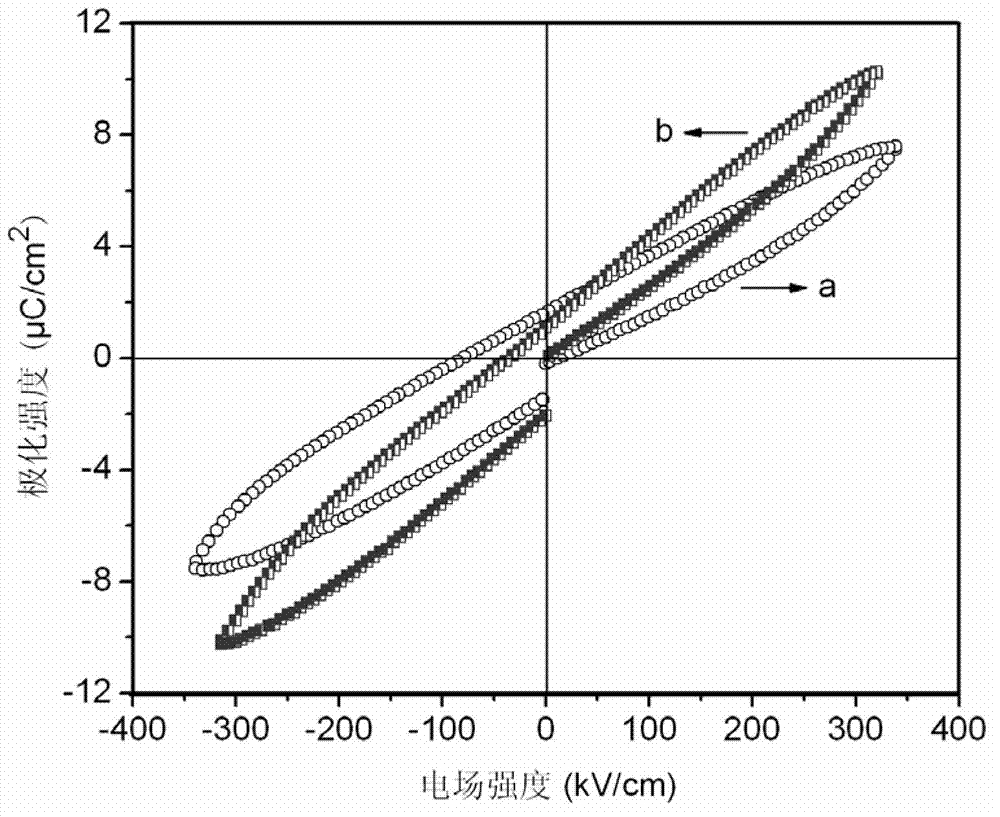

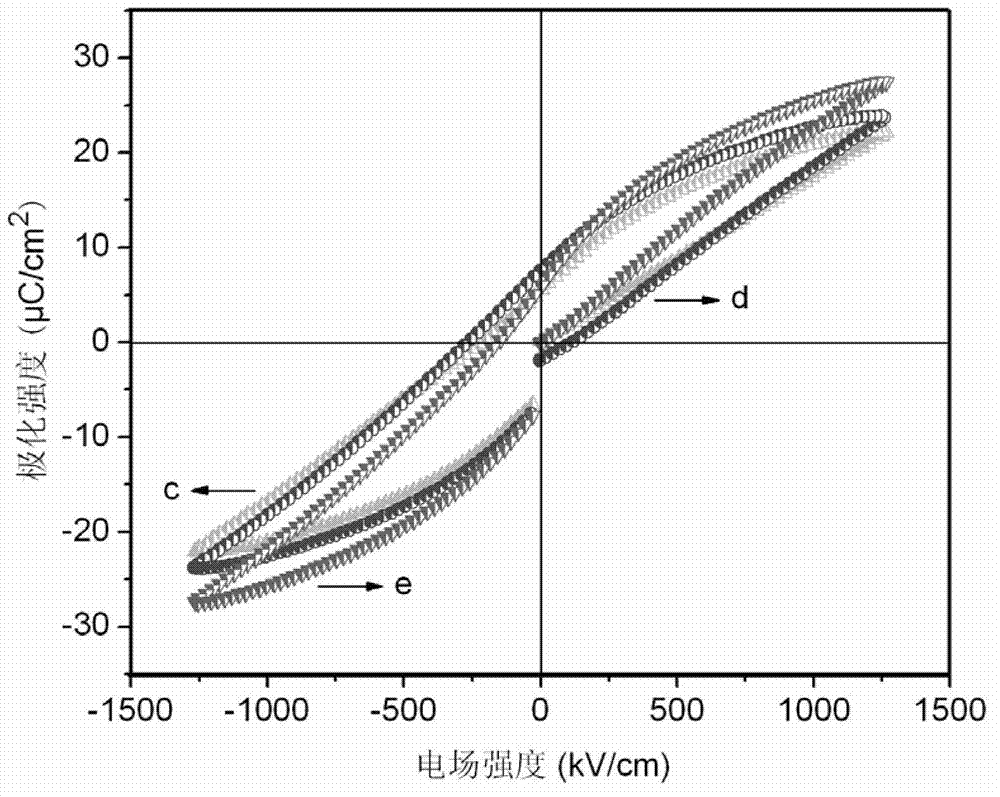

[0016] Specific Embodiment 1: In this embodiment, a multiferroic thin film with complete crystallization and no impurity phase is composed of barium strontium titanate-based sol and BFO-based sol on cleaned Pt / Ti / SiO 2 / Si(100) substrate prepared by spin coating method, thermal decomposition method and rapid annealing method.

[0017] The multiferroic thin film with complete crystallization and no impurity phases described in this embodiment can prevent the BFO-based thin film from reacting with the Pt bottom electrode, and is beneficial to obtain a multiferroic thin film with high crystallinity.

[0018] The multiferroic thin film with complete crystallization and no impurity phases described in this embodiment has no impurity phases, and effectively improves its multiferroic properties such as ferroelectricity and ferromagnetism.

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the preparation method of the strontium barium titanate-based sol is carried out according to the following steps: ①Hydrolysis process: according to the chemical formula Ba x Sr 1-x A y Ti 1-y o 3 , according to the ratio of Ba element, Sr element, A element and Ti element molar ratio is x: (1-x): y: (1-y) the raw material that weighs joins the ratio that is made of ethylene glycol methyl ether, acetylacetone, ice In a mixed solvent composed of acetic acid and deionized water, stir at room temperature until fully dissolved to obtain a mixed solution for use; ②Dehydration process: Stir and mix polyethylene glycol 400 and acetic anhydride with the mixed solution prepared in step ①, and then in Stir continuously at 20-40°C for 0.5h-2h to obtain the barium strontium titanate-based solution to be prepared; ③polymerization process: let the barium-strontium titanate-based solutio...

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the preparation method of the BFO-based sol is carried out according to the following steps: ①Hydrolysis process: according to the chemical formula Bi z B 1-z Fe k C 1-k o 3, the molar ratio of Bi element, B element, Fe element and C element is z: (1-z): k: (1-k) The ratio of raw materials weighed is added to ethylene glycol methyl ether, acetylacetone, In a mixed solvent composed of glacial acetic acid and deionized water, stir until fully dissolved at room temperature to obtain a mixed solution for use; ②Dehydration process: stir and mix polyethylene glycol 400 and acetic anhydride with the mixed solution prepared in step ①, and then Stir continuously at 20-40°C for 0.5h-2h to obtain the BFO-based solution to be prepared; ③polymerization process: put the BFO-based solution prepared in step ② at room temperature for 1-4 days to obtain BFO base sol; the volume ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com