Method for preparing RexCe1-xOy/M2Zr2O7 double-layer buffer layer by chemical solution deposition

A technology of chemical solution deposition and buffer layer, which is applied in the direction of solid-state chemical plating, coating, metal material coating process, etc., can solve the problems that it is difficult to obtain a high-performance YBCO superconducting layer and the critical thickness of a single-layer buffer layer is small , to achieve the effects of increased critical thickness, reduced preparation cost, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of chemical solution deposition method prepares Sm 0.2 Ce 0.8 o 1.9 / La 2 Zr 2 o 7 The method of the double buffer layer consists of the following steps in turn:

[0026] a.La 2 Zr 2 o 7 (LZO) film preparation:

[0027] Appropriate amount of La(NO 3 ) 3 .6H 2 O and ZrO(NO 3 ) 3 .2H 2 O according to ion concentration La +3 : Zr +4 It is dissolved in ethylene glycol methyl ether at a ratio of 1:1, in which hydroxyethyl methyl ether is added according to the volume ratio of 1 mole (gadolinium nitrate + zirconium nitrate): 0.5-3 liters, and 5wt.% oxidized polyethylene 20000 synthetic colloid is added. The colloid was evenly spin-coated on the NiW base tape, and the obtained wet film was dried to remove the water, and then placed in a channel with H 2 In the heat treatment furnace with / Ar reducing atmosphere, the temperature was first raised to 350°C at a rate of 5°C / min to allow the organic matter and nitrate to be fully decomposed, an...

Embodiment 2

[0030] Embodiment 2: A kind of chemical solution deposition method prepares Gd 0.3 Ce 0.7 o 1.85 / Gd 2 Zr 2 o 7 The method of the double buffer layer consists of the following steps in turn:

[0031] a.Gd 2 Zr 2 o 7 (GZO) film preparation:

[0032] Appropriate amount of Gd(NO 3 ) 3 .6H 2 O and ZrO(NO 3 ) 3 .2H 2 O according to ion concentration Gd +3 : Zr +4 It is dissolved in ethylene glycol methyl ether at a ratio of 1:1, wherein hydroxyethyl methyl ether is added according to the volume ratio of 1 mole (gadolinium nitrate + zirconium nitrate): 0.5-3 liters, and 3wt.% oxidized polyethylene 20000 synthetic colloid is added. The colloid was coated on the NiW base tape by the pulling method, and the obtained wet film was dried to remove the water, and then placed in a H 2 In the heat treatment furnace with / Ar reducing atmosphere, first raise the temperature to 600°C at a rate of 1°C / min to fully decompose the organic matter and nitrate, then directly raise the...

Embodiment 1

[0035] In embodiment 1 and embodiment 2, implement with rare earth Sm and rare earth Gd, wherein rare earth yttrium (Y), lanthanum (La), praseodymium (Pr), neodymium (Nd), europium (Eu), terbium (Tb), Dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), and lutetium (Lu) can all be implemented in the above manner.

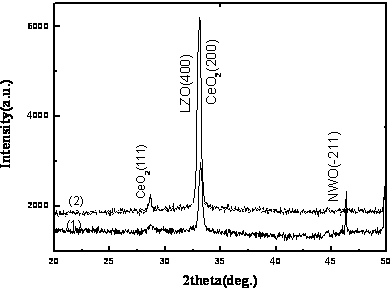

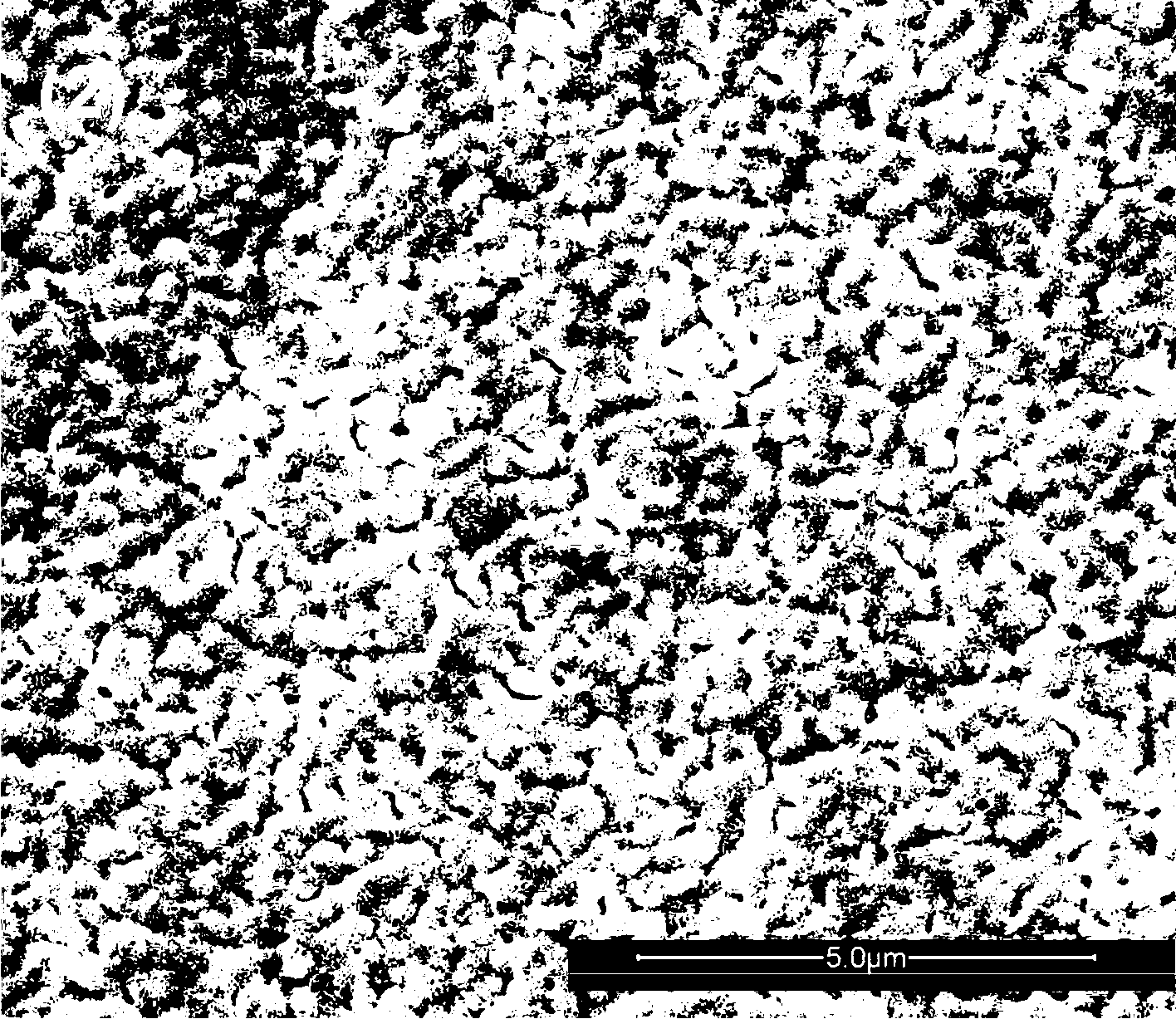

[0036] figure 1 Sm prepared for the implementation case 0.2 Ce 0.8 o 1.9 / La 2 Zr 2 o 7 / NiW buffer layer X-ray diffraction pattern, it can be seen from the figure that all the prepared double-layer buffer layers have a good biaxial texture; Fig. 2 Sm 0.2 Ce 0.8 o 1.9 / La 2 Zr 2 o 7 / SEM picture of the NiW double-layer buffer layer. From the figure, it can be seen that the surface of the buffer layer is flat and dense, without microcracks, and has good surface properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com