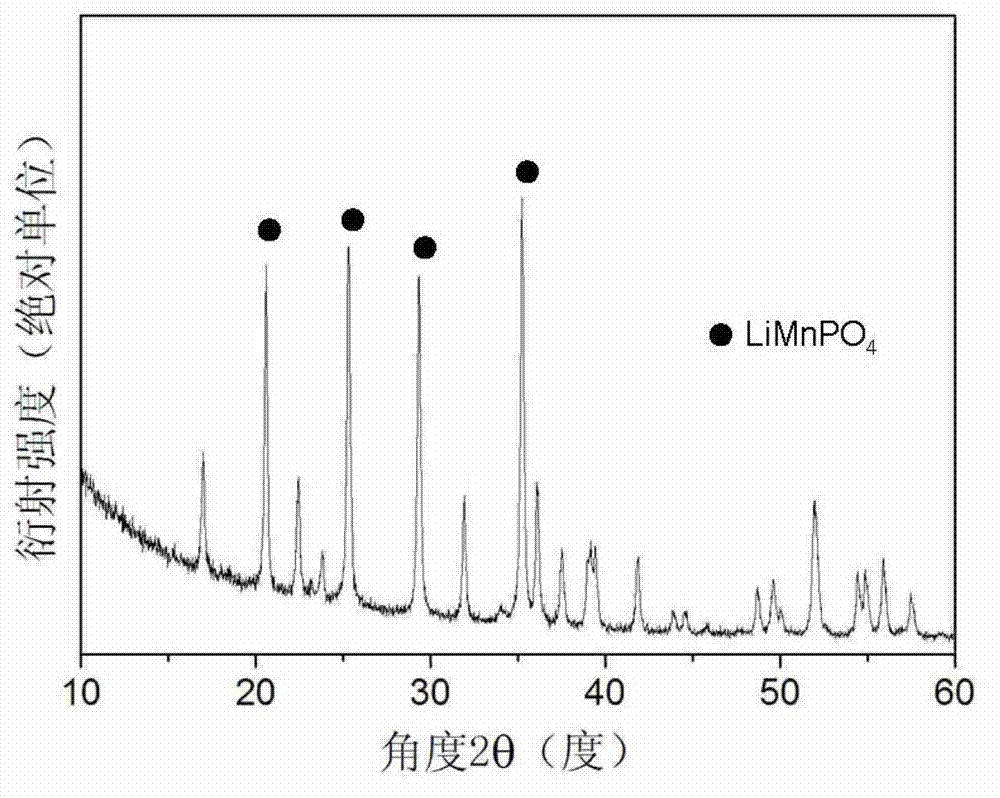

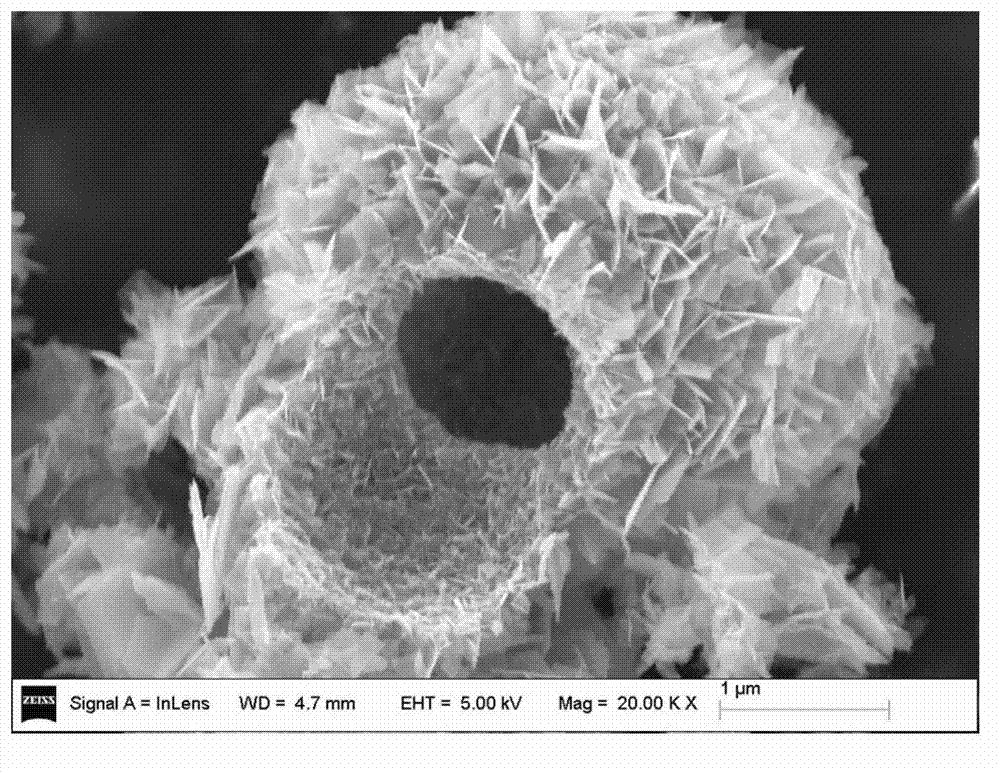

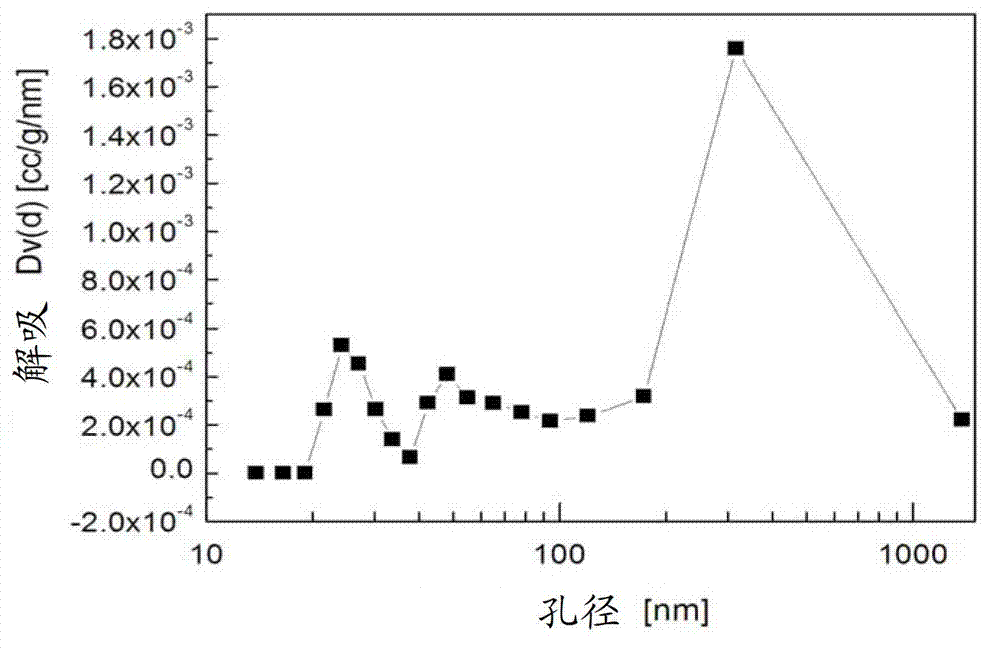

Lithium manganese phosphate cathode material and preparation method thereof

A technology of lithium manganese phosphate and cathode material, which is applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of unstable crystal structure, affecting the cycle performance of materials, and general electrochemical performance of lithium manganese phosphate materials. Improve discharge capacity and cycle performance, facilitate infiltration and storage, de-intercalation and convenient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 115.3g of 85wt% phosphoric acid, 93.1g of manganese carbonate, 15.17g of iron oxide, 46.16g of lithium hydroxide, 80.92g of sucrose and 2.7g of cetyltrimethylammonium bromide were mixed and dispersed in 824.4g of deionized water, Obtain a suspension with a solid content of 30wt%; then add the obtained suspension into the reaction kettle, heat it to 150°C for 15 hours under airtight conditions, and after the reaction is completed and cooled to room temperature, the reaction product is washed, filtered, and dried , to obtain the lithium manganese phosphate precursor powder; then the obtained lithium manganese phosphate precursor powder was calcined at a high temperature for 8 hours under the protection of nitrogen, the roasting temperature was 500 ° C, and then cooled to room temperature to obtain a lithium manganese phosphate positive electrode with a hollow spherical structure material whose molecular formula is LiMn 0.81 Fe 0.19 PO 4 / C.

[0062] The components and ...

Embodiment 2

[0072] 138.66g of diammonium hydrogen phosphate, 220.58g of manganese acetate, 7.9g of titanium dioxide, 38.79g of lithium carbonate, 40.6g of sucrose and 20.3g of triton were mixed and dispersed in 700g of deionized water to obtain a suspension with a solid content of 40%; Then add the obtained suspension into the reaction kettle, heat to 200° C. for 10 h under airtight conditions, and after the reaction is completed and cooled to room temperature, the reaction product is washed, filtered, and dried to obtain lithium manganese phosphate precursor powder; Then the obtained lithium manganese phosphate precursor powder was calcined at a high temperature for 5 hours under the protection of a nitrogen atmosphere at a temperature of 600°C, and then cooled to room temperature to obtain a lithium manganese phosphate positive electrode material with a hollow spherical structure, whose molecular formula is LiMn 0.9 Ti 0.1 PO 4 / C.

[0073] According to the detection method of Example...

Embodiment 3

[0076] Mix 126.53g of diammonium hydrogen phosphate, 86.07g of manganese dioxide, 0.4g of magnesium oxide, 65.99g of lithium acetate, 55.80g of polyvinyl alcohol and 27.8g of citric acid, and disperse them in 1160g of deionized water to obtain a suspension with a solid content of 20%. Then add the obtained suspension into the reaction kettle, heat it to 250°C under airtight conditions and react for 5h, after the reaction is completed and cooled to room temperature, the reaction product is washed, filtered, and dried to obtain the lithium manganese phosphate precursor powder body; then the obtained lithium manganese phosphate precursor powder is roasted at high temperature for 2 hours under the protection of nitrogen atmosphere, the roasting temperature is 700 ° C, and then cooled to room temperature to obtain a lithium manganese phosphate positive electrode material with a hollow spherical structure, and its molecular formula is LiMn 0.99 Mg 0.01 PO 4 / C.

[0077] According ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com