A kind of preparation method of block polymer-nanometer metal thin layer composite conductive material

A technology of block polymers and nano-metals, which is applied in the field of functional composite material preparation to achieve good electrical conductivity, good material performance, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

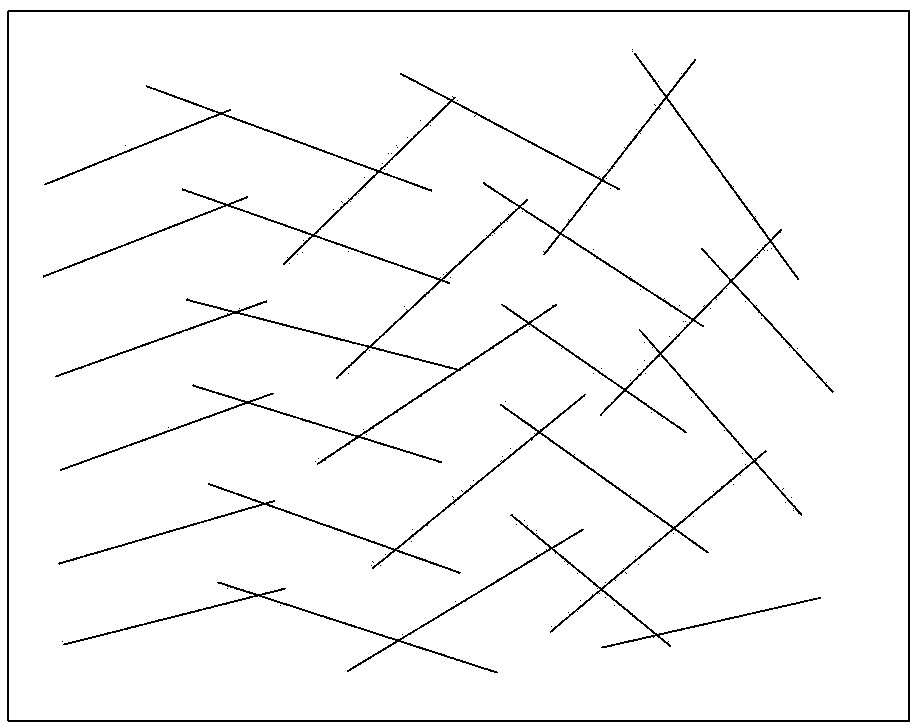

[0029] The first step is to synthesize amphiphilic block polymer polystyrene-polyacrylic acid (PS-PAA) by RAFT polymerization method. Weigh 0.0353g of self-made RAFT reagent, 10ml of dioxane solvent and 2g of styrene, respectively. Add 0.0055g of azobisisobutyronitrile into a 50ml round-bottomed flask, put it into the rotor and seal it with a rubber stopper, pass nitrogen through a long needle for 10 minutes to remove the oxygen in the round-bottomed flask, then seal it well, and put it into the 90 Take it out after heating in an oil bath at ℃ for 3 hours, and the product is precipitated by n-hexane three times, and then dried in a vacuum oven for 24 hours to obtain PS; then take 2 g of PS and 14.1875 g of tert-butyl acrylate PtBA and repeat the step of preparing PS in the previous step That is to obtain PS-PtBA, add 5ml of trifluoroacetic acid to the obtained product and hydrolyze it for 24 hours to obtain PS-PAA. According to weighing design, its total molecular weight is 100...

Embodiment 2

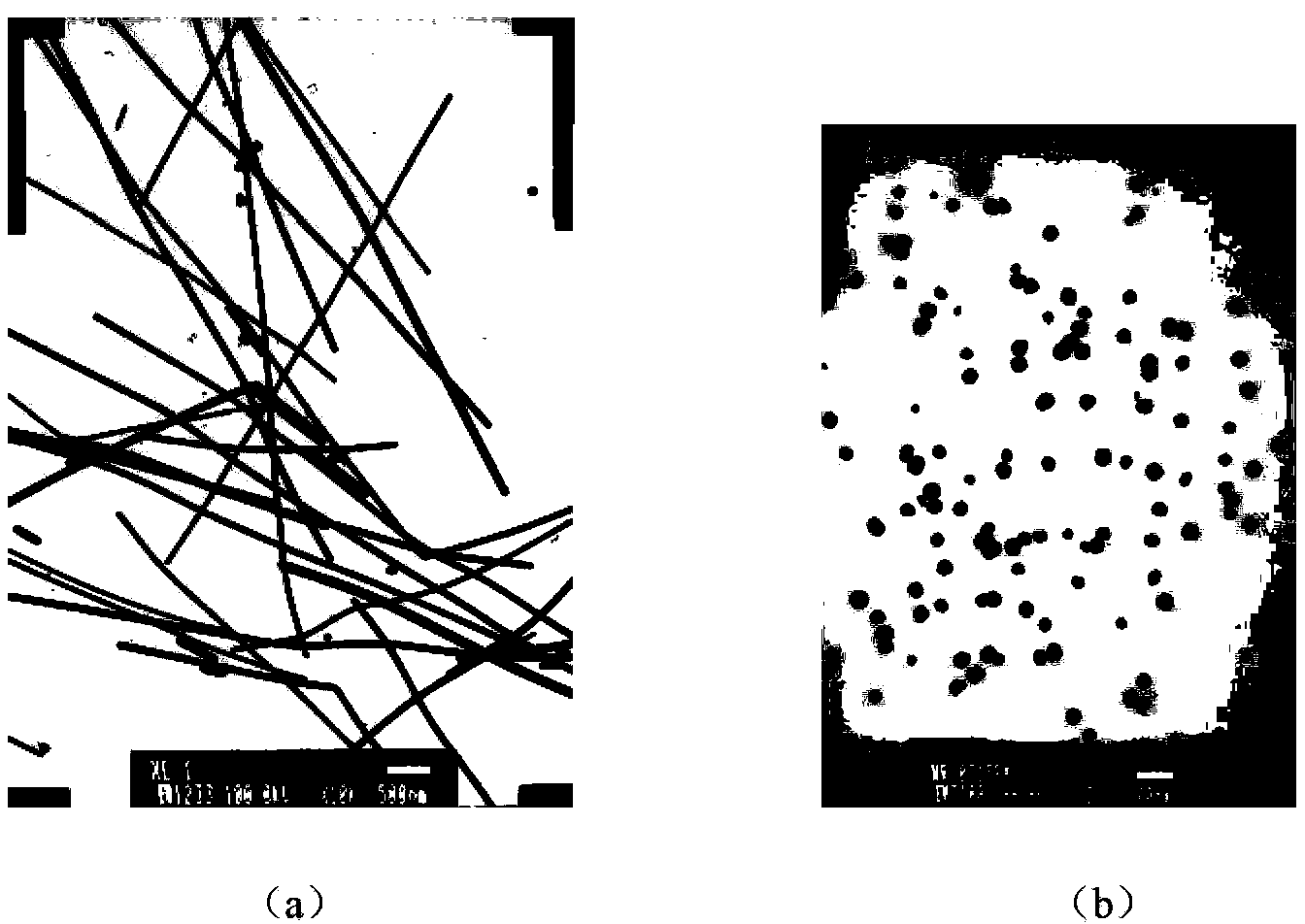

[0035]In the first step, referring to the preparation method of the amphiphilic block polymer in Example 1, PS-P2VP with a total molecular weight of 20,000 and a segment length ratio of 2:8 was prepared, and dissolved in acetone to form a 5wt% solution ; With reference to the preparation method of the nano-silver wire in Example 1, the nano-gold wire is prepared, and added into acetone to configure a 1wt% homogeneous solution;

[0036] In the second step, the prepared two solutions are mixed at a volume ratio of 2:1 to obtain a mixed solution in which the ratio of the gold mass to the amphiphilic block polymer is 10%, and the ultrasonic vibration is used to fully mix it to become a uniform composite solution;

[0037] In the third step, the composite solution obtained is spin-coated to obtain a composite thin film layer, and dried to obtain the product; the resulting composite thin film layer product is tested for its electrical conductivity by the four-probe method, and is uni...

Embodiment 3

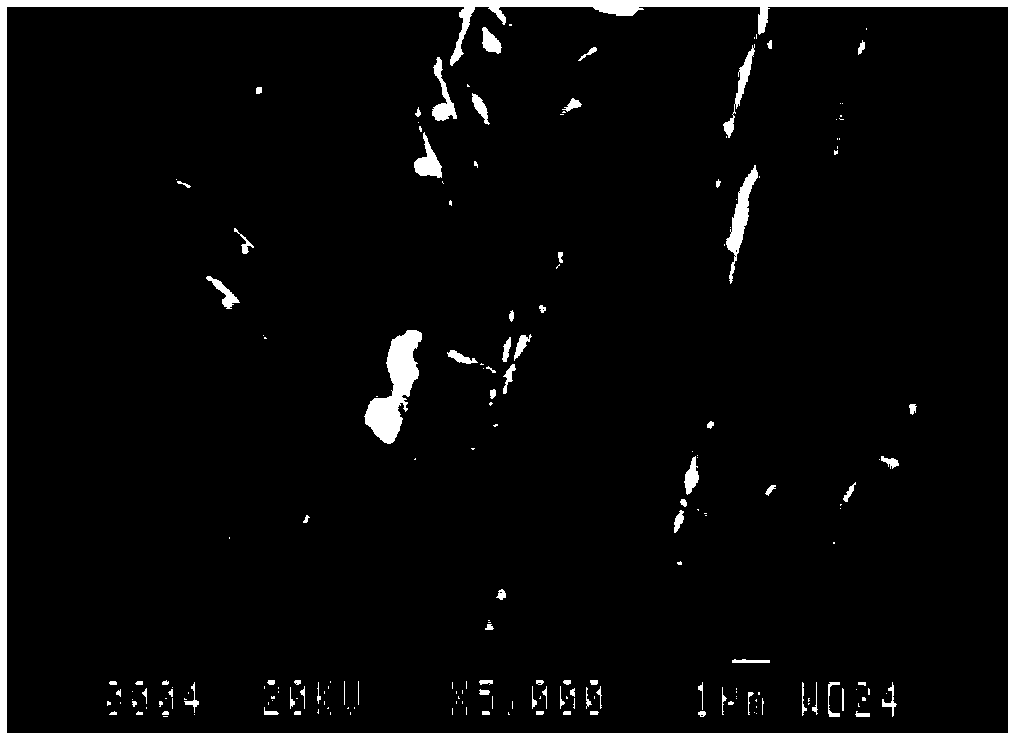

[0041] The first step refers to the preparation method of the amphiphilic block polymer in Example 1 to prepare the amphiphilic block polymer PBA-PAA, which has a total molecular weight of 20000 and a segment length ratio of 4:6, soluble in Acetone is configured into a 5wt% solution; the preparation of nano-copper particles: Dilute the mother liquor containing a certain amount of protective agent (4ml of cetyltrimethylammonium bromide (CTAB) with a concentration of 50mMol to 15ml with distilled water, and inject it into Put 45ml of copper sulfate solution of 0.038g hydrazine hydrate (80%) in a 100ml three-necked flask, and pass nitrogen gas for 10 minutes to eliminate the oxygen dissolved in the reactor and the solution; then use 5ml of a certain concentration of copper sulfate solution with Add the syringe dropwise into the reducing agent, stir vigorously, and reflux at 70°C for 1 hour to prepare nano-copper particles, which are added to acetone to form a 1wt% uniform solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com