Preparation method and application of polymeric flocculant

A flocculant and reaction system technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor removal of heavy metal ions in sewage, low regeneration ability of flocculant, no preparation method and application, etc., and achieve wide application effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

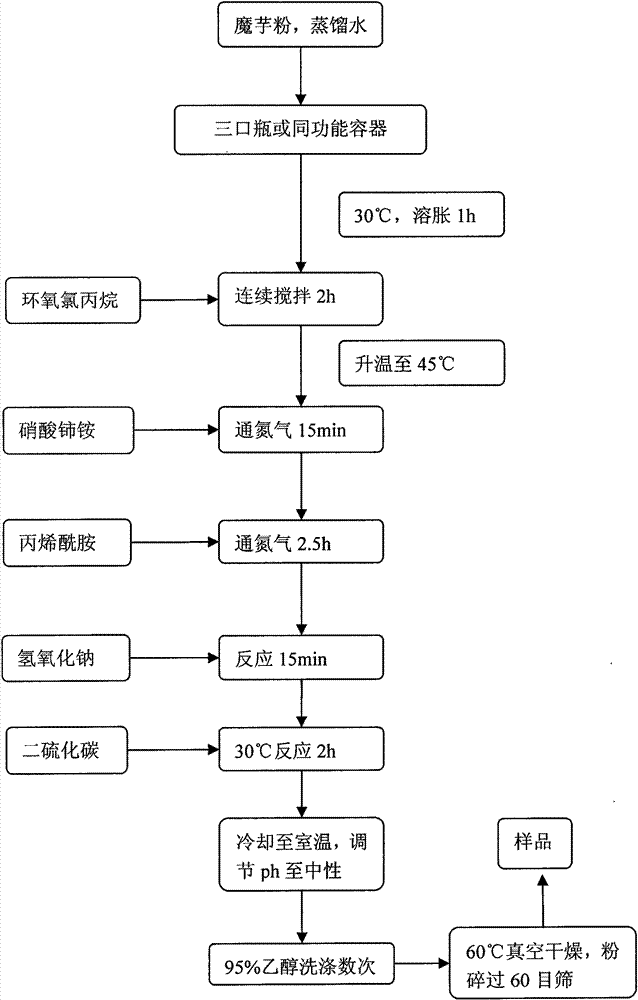

Method used

Image

Examples

Embodiment 2

[0086] Embodiment 2 adsorption experiment

[0087] 1. Experimental materials: the same as in Example 1.

[0088] 2. Experimental method

[0089] (1) Feeding amount to Cu 2+ The effect of adsorption performance

[0090] Take 50mg / L of Cu 2+ The solution was 100mL, the pH value of the solution was adjusted to 5.0, different amounts of flocculant CKAX were added, and the flocculation experiment was carried out at room temperature. The experimental results were as follows Figure 7 shown.

[0091] Depend on Figure 7 It can be seen that with the increase of sample dosage, the effect of CKAX on metal ion Cu 2+ The removal rate of Cu 2+ The removal rate showed a downward trend instead. This may be because the excessive flocculant will stick to the surface of the floc, and the xanthic acid group on the flocculant will be negatively charged after dissociation, so that the floc also bears a negative charge, thereby generating electrostatic repulsion and making it difficult to c...

Embodiment 3

[0127] Embodiment 3 analysis and regeneration experiment

[0128] The desorption effects of hydrochloric acid and nitric acid on the CKAX loaded with copper ions were investigated. For load Cu2+ The optimal desorption conditions of CKAX are: room temperature (25°C), hydrochloric acid 0.2mol / L or HNO 3 0.2mol / L, desorb for 30min. Under these conditions, the adsorbent regeneration experiment was carried out, and the specific steps were as follows:

[0129] 1. Experimental materials: as described in Example 1.

[0130] 2. Experimental method

[0131] Prepare 1000mg / L copper ion standard aqueous solution according to GB7475-87, and then dilute it with distilled water to different concentrations as needed. Take 100mg / L copper ion solution, pour it into a 250mL Erlenmeyer flask, then add 0.1g flocculant CKAX, stir rapidly (150r / min) at room temperature for 2min, stir slowly (50r / min) for 10min, and let stand for 15min. Centrifuge for 10min (4200r / min), take the supernatant and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com