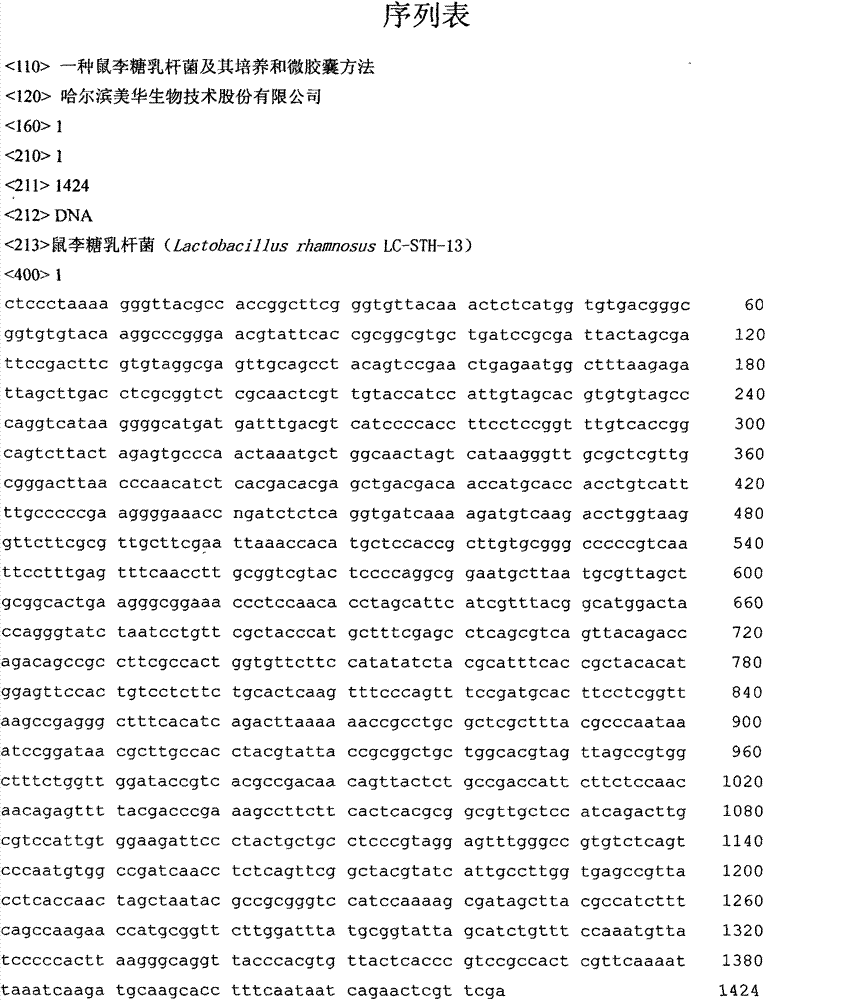

Lactobacillus rhamnosus, cultivation of lactobacillus rhamnosus and microcapsule method

A technology of Lactobacillus rhamnosus and microcapsules, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., to achieve the effects of high lactic acid production concentration, improved gastrointestinal tract, and short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The percentages involved in this embodiment are all percentages by weight.

[0037] 1. First collect samples from the feces of normal adults, sterilize the sampling tools and various sampling containers, and perform multi-point sampling.

[0038] 2. Dilute the collected samples: mix the collected samples evenly under sterile conditions, weigh 20 grams of samples, dissolve them in 100 mL of sterile water, which contains 80-100 glass beads, and shake vigorously for 10 minutes , stand still for one minute, draw 1mL supernatant with a 1mL sterile pipette, transfer to a 9mL sterile water test tube, shake thoroughly, then take 1mL sample from this diluted sample and transfer it to a 9mL sterile test tube, shake thoroughly Evenly, dilute in turn until it reaches 10 -5 .

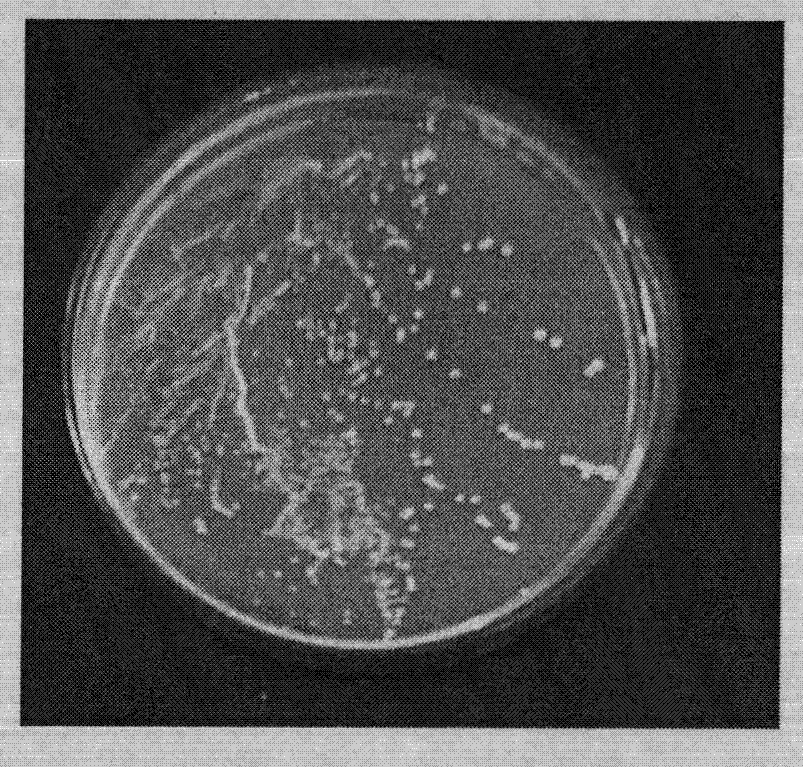

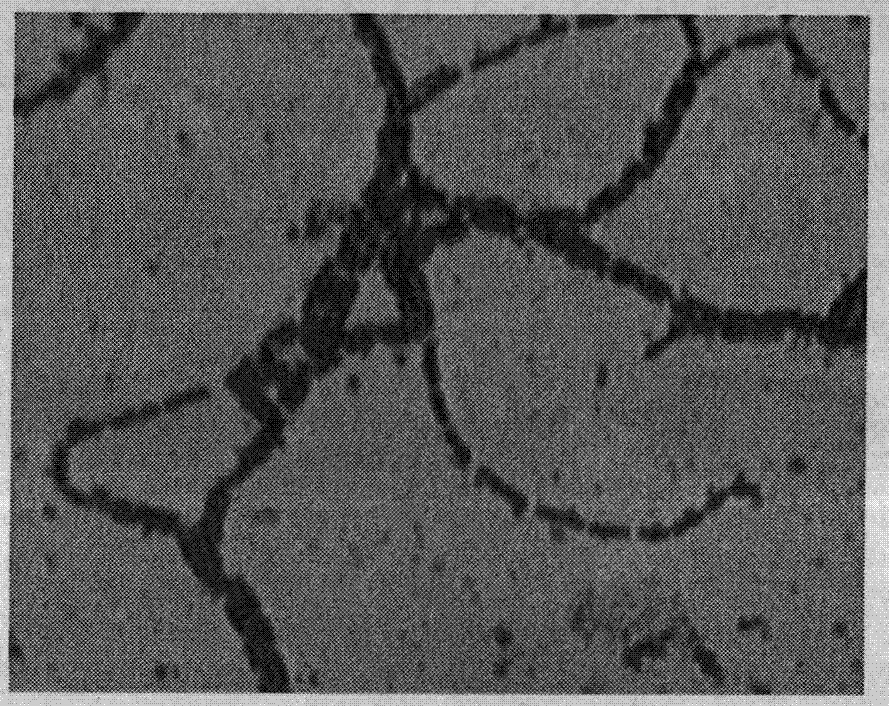

[0039] 3. Coating and separation: Take out 0.1mL samples from the above-mentioned diluted samples with 0.1mL sterile pipettes, transfer them into the BCP agar plate medium, use a sterile triangular scraper ...

example 1

[0055] The culture method of Lactobacillus rhamnosus LC-STH-13, medium formula: solution is water, glucose 65.0g / L, yeast powder 15.0g / L, beef powder 28.0g / L, soybean peptone 30.0g / L, KH 2 PO 4 3.0g / L, anhydrous sodium acetate 3.0g / L, ammonium citrate 2.0g / L, Tween 801.5mL / L, MgSO 4 ·7H 2 O 1.0g / L, MnSO 4 4H 2 O 0.5g / L, whey powder 19.5g / L, fructooligosaccharides 18.5g / L, casein hydrolyzate 9.5g / L, pH6.5, culture temperature 37℃, culture time 16h.

[0056]After the cultivation, centrifuge at 5000rpm, and then add lyoprotectant for microcapsule embedding. Glutamic acid 50.0g / L. The mass ratio of the embedding agent to the wet bacteria slime is 1:1. After mixing evenly, freeze-dry to obtain the freeze-dried bacteria powder. The number of viable bacteria in the freeze-dried bacteria powder is ≥1.0×10 10 cfu / g.

example 2

[0058] Lactobacillus rhamnosus LC-STH-13, the culture method is as follows: the solution is water, the medium formula glucose 10.0g / L, yeast powder 5.0g / L, beef powder 5.0g / L, soybean peptone 2.0g / L, KH 2 PO 4 0.5g / L, anhydrous sodium acetate 0.1g / L, ammonium citrate 0.1g / L, Tween 800.5mL / L, MgSO 4 ·7H 2 O0.1g / L, MnSO 4 4H 2 O 0.2g / L, whey powder 10.0g / L, fructooligosaccharides 10.0g / L, casein hydrolyzate 5.0g / L, pH4.5, culture temperature 32℃, fermentation time 36h; after the culture, 5000rpm Centrifuge, then add lyoprotectant for microcapsule embedding, microcapsule embedding agent formula: skimmed milk powder 50.0g / L, glycerin 10.0g / L, trehalose 50.0g / L, γ-polyglutamic acid 10.0g / L; the mass ratio of embedding agent and wet bacteria slime is 1:1, after mixing evenly, freeze-dry to obtain freeze-dried bacteria powder, the number of live bacteria of freeze-dried bacteria powder is ≥1.0×10 10 cfu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com