Quasicrystal complex phase hydrogen storage alloy containing magnesium, titanium, vanadium and nickel and preparation method thereof

A hydrogen storage alloy and quasicrystal technology, which is applied in the field of magnesium-titanium-vanadium-nickel quasicrystal composite hydrogen storage alloy and its preparation, can solve the problem that there are no patent publications and article reports for the manufacturing method, and the electrochemical hydrogen storage is not fully extended. The problems of difficulty in the preparation of single-phase quasicrystals can achieve excellent electrochemical hydrogen storage performance, improve catalytic activity and cycle life, and promote mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a magnesium-titanium-vanadium-nickel quasicrystalline multiphase hydrogen storage alloy, comprising the following steps:

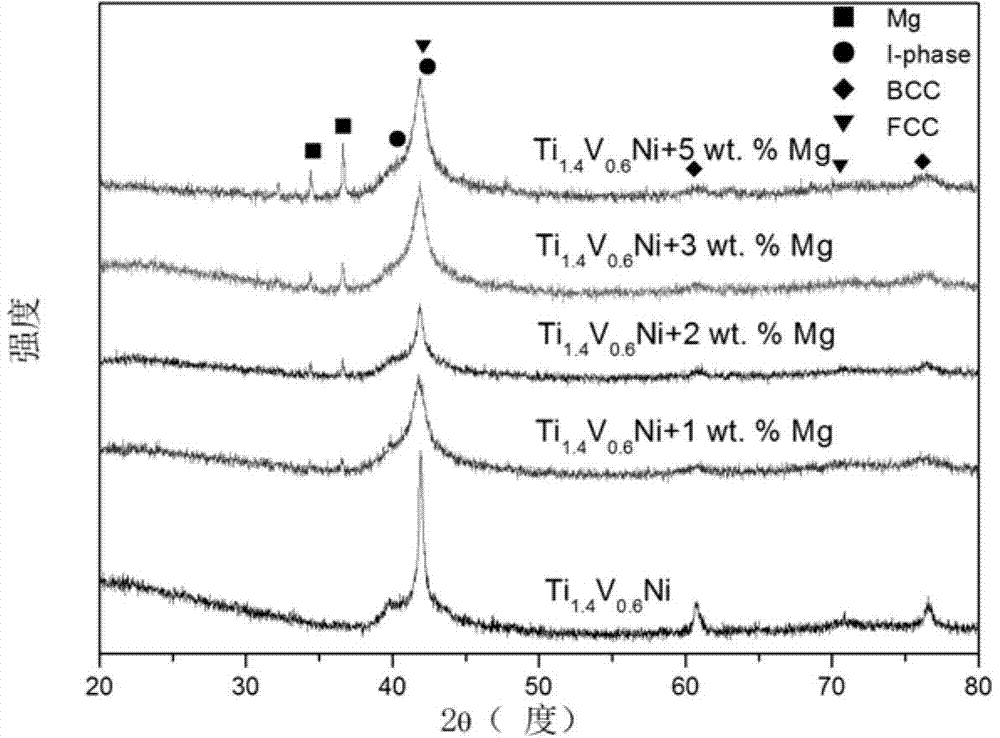

[0035] Step 1: According to Ti 1.4 V 0.6 Composition expression of Ni quasicrystal multi-phase hydrogen storage material Weigh Ti metal, V metal and Ni metal, melt them into alloy ingots in vacuum electric arc furnace, and prepare Ti with I phase through vacuum quenching and casting machine. 1.4 V0.6 Ni quasicrystal complex phase material ribbon;

[0036] Step 2: The Ti obtained in Step 1 1.4 V 0.6 Ribbon grinding of Ni quasicrystal complex phase materials to form Ti 1.4 V 0.6 Ni quasicrystal composite material powder;

[0037] Step 3: Weigh magnesium powder and the Ti obtained in step 2 respectively 1.4 V 0.6 Ni quasicrystalline composite material powder is put into a ball milling tank for ball milling to obtain a magnesium-titanium-vanadium-nickel quasicrystalline composite-phase h...

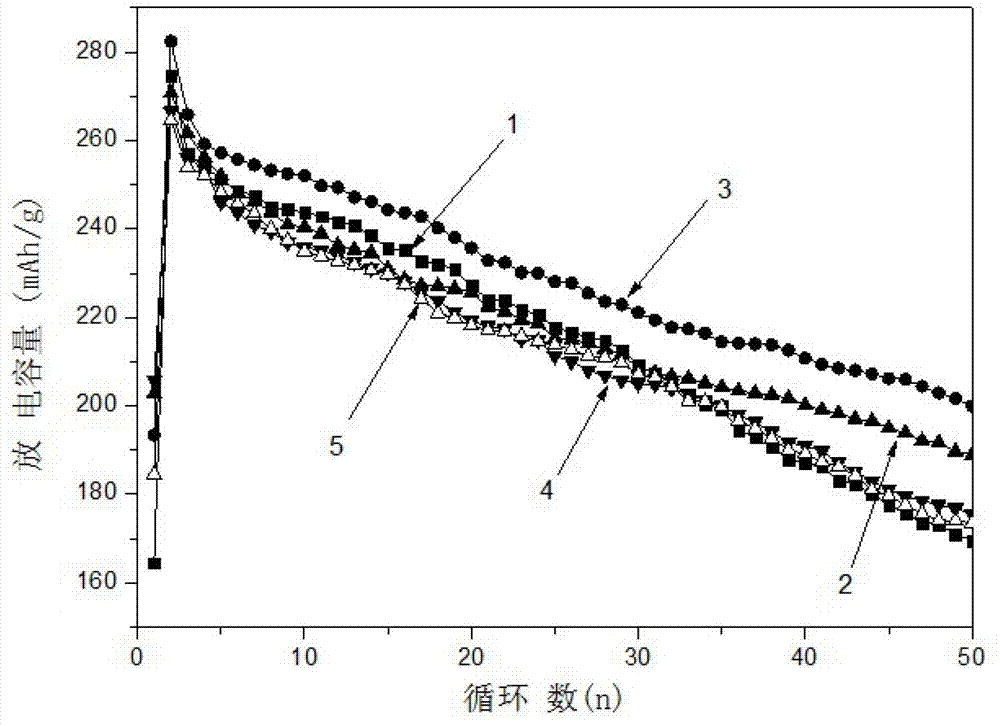

Embodiment 1

[0046] Example 1: Magnesium-titanium-vanadium-nickel quasicrystal composite phase hydrogen storage alloy Expression: Ti 1.4 V 0.6 Ni + 1 wt% Mg, the material is prepared as follows:

[0047] (1) Vacuumize the vacuum arc melting furnace to 10 -3 After Pa is filled with 0.5 atmospheres of high-purity argon with a purity of 99.999% (volume percentage) as a protective gas, 10Ti metal (99.7% purity), 4.56 V metal (99.9% purity) and 8.756 Ni metal (99.5% purity) Put it into a vacuum electric arc furnace for smelting, the arc current is 300 A, smelting 4 times, smelting for 2 minutes each time, and cooling naturally to obtain an alloy ingot; put the above alloy ingot into a quartz tube with a small hole of 0.5 mm at the bottom , placed in the vacuum quenching casting all-in-one machine, vacuumed to 3.0×10 -3 MPa, filled with high-purity argon to 0.5 atmospheric pressure, and melted the alloy nails in the quartz tube at 2000 °C by induction heating, the injection pressure was 0.1 ...

Embodiment 2

[0051] Example 2: Magnesium-titanium-vanadium-nickel quasicrystal composite phase hydrogen storage alloy Expression: Ti 1.4 V 0.6 Ni + 2 wt% Mg, the material is prepared as follows:

[0052] Step (1) and step (2) are the same as embodiment 1;

[0053] (3) Accurately weigh 9.8g Ti obtained in the above step (2) 1.4 V 0.6 Ni quasicrystal composite material powder and 0.2g magnesium powder are put into a stainless steel ball mill tank in a glove box filled with a high-purity argon atmosphere for ball milling. The diameter of the steel ball is 10mm, the ratio of ball to material is 15:1, and the vibration frequency is 800 rpm. / min, ball milling time 20 min, remove the ball mill jar from the ball mill, open the ball mill jar in a high-purity argon atmosphere glove box to obtain a magnesium-titanium-vanadium-nickel quasicrystal hydrogen storage alloy, and seal it in a desiccator for storage .

[0054] The XRD pattern of the magnesium-titanium-vanadium-nickel quasicrystal compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com