Special organic fertilizer and preparation method thereof

A kind of organic fertilizer, special technology, applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of high moisture content of leftovers, secondary environmental pollution, limited source of raw materials, etc., achieve highly active soil, improve soil, and improve fertilizer efficiency and the effect of fertilizer activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

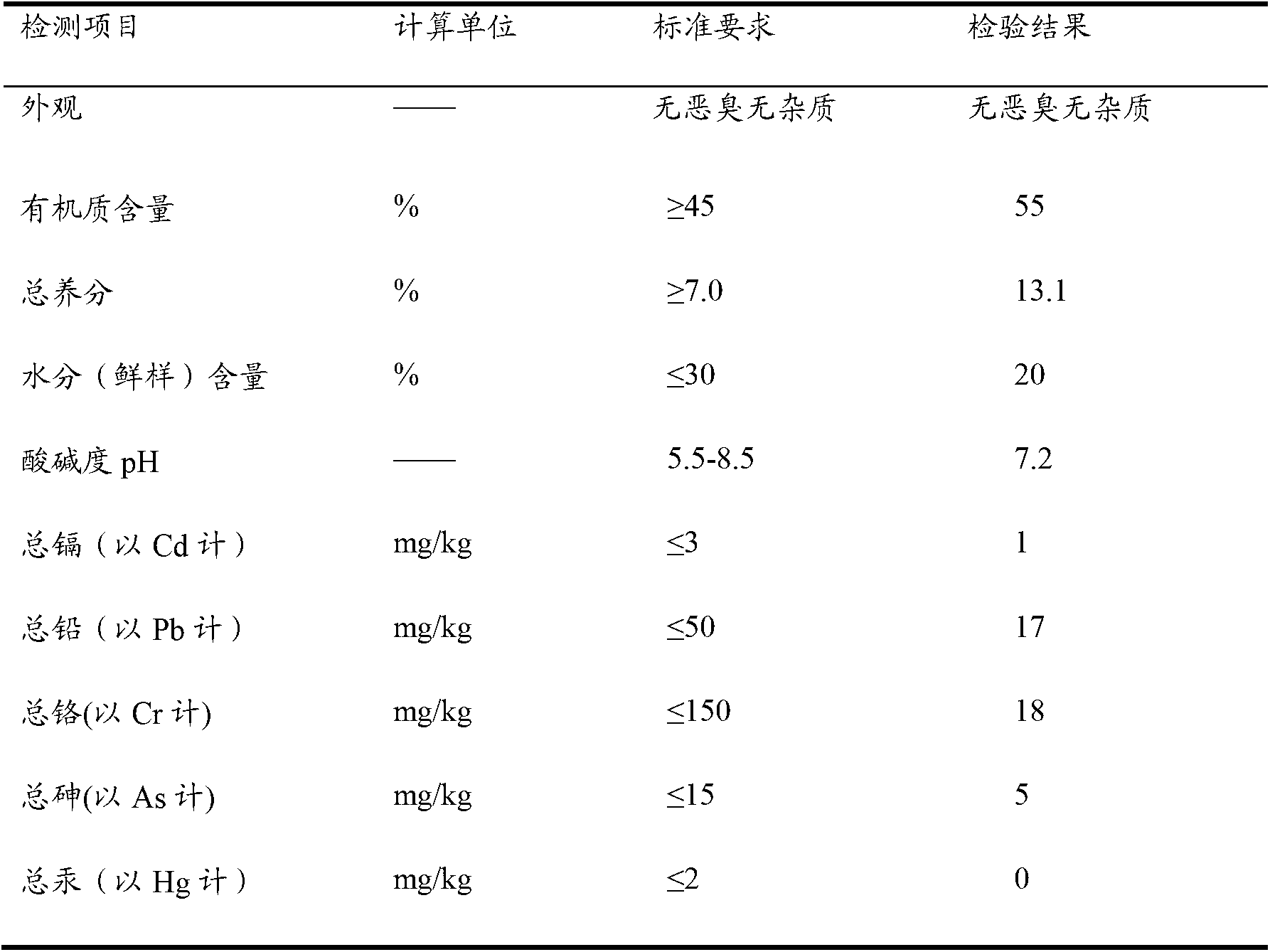

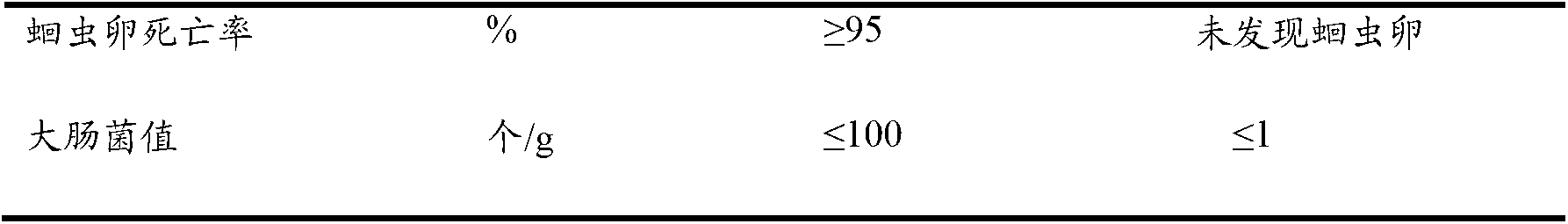

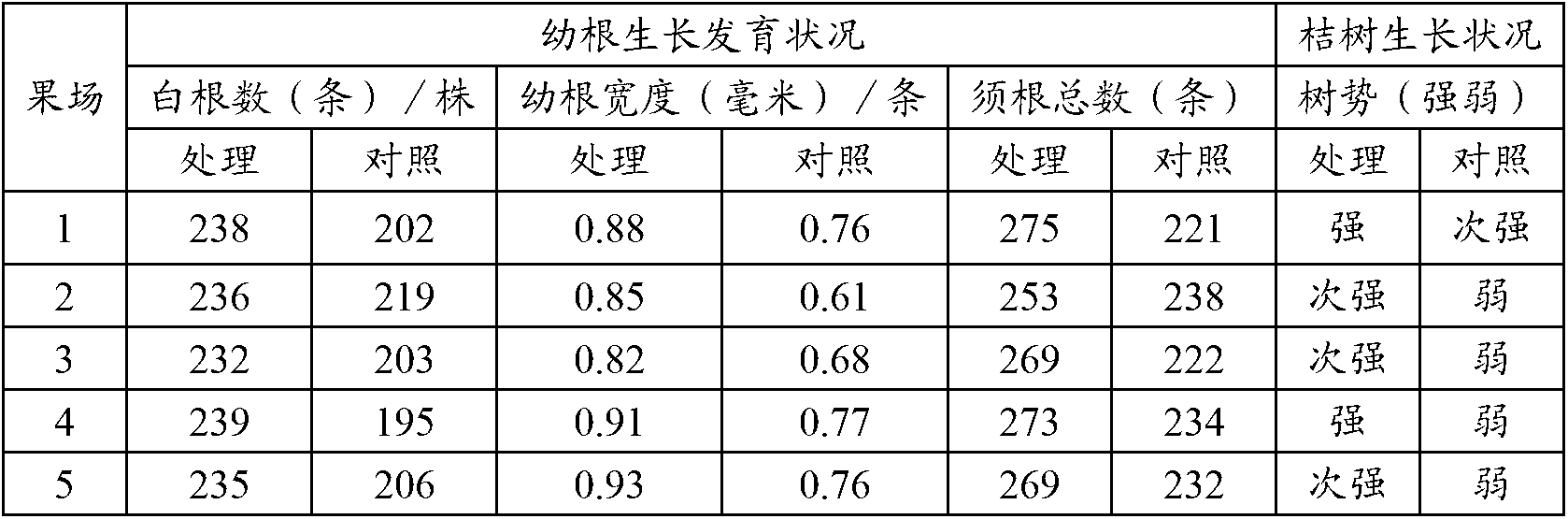

[0036] Embodiment 1 A kind of special organic fertilizer preparation

[0037] Preparation of compound amino acid hydrolyzate: take 1 ton of fresh shrimp head, crush it, add mixed enzyme and water after sterilizing at 100°C, and make it after 40 hours of constant temperature enzymolysis at 60°C, wherein the weight ratio of raw materials, water and mixed enzyme is : 100:20:0.03. The mixed enzyme is a compound enzyme mainly composed of protease and acid cellulase, and the others are chitinase. Wherein protease and acid cellulase account for more than 90% of the total amount of mixed enzymes, the dosage ratio of protease and acid cellulase is 7:3, and the protease is bromelain.

[0038] Preparation of organic matter: 1440kg of sludge with a moisture content of 65%, mixed evenly with 480kg of peanut bran and 480kg of humic acid, were ventilated and fermented at room temperature for 3 days.

[0039] Add the compound amino acid hydrolyzate and organic matter into the blender, stir ...

Embodiment 2

[0044] Embodiment 2 A kind of special organic fertilizer preparation

[0045] Preparation of compound amino acid hydrolyzate: take 750kg of fresh shrimp heads, crush them, add mixed enzyme and water after sterilizing at 100°C, and prepare after 40 hours of constant temperature enzymolysis at 60°C, wherein the weight ratio of raw materials, water and mixed enzyme is: 100:20:0.03. The mixed enzyme is a compound enzyme mainly composed of protease and acid cellulase, and the others are chitinase. Wherein protease and acid cellulase account for more than 90% of the total amount of mixed enzymes, the dosage ratio of protease and acid cellulase is 7:3, and the protease is trypsin.

[0046] Preparation of organic matter: After mixing 990kg of sludge with a moisture content of 65%, 330kg of peanut bran, and 330kg of humic acid, it was ventilated and fermented at room temperature for 3 days.

[0047] Add the compound amino acid hydrolyzate and organic matter into the blender, stir evenl...

Embodiment 3

[0048] Embodiment 3 A kind of special organic fertilizer preparation

[0049] Preparation of compound amino acid hydrolyzate: take 1250kg of fresh shrimp head, crush it, add mixed enzyme and water after sterilizing at 100°C, and make it after constant temperature enzymolysis at 60°C for 40 hours, wherein the weight ratio of raw materials, water and mixed enzyme is: 100:20:0.03. The mixed enzyme is a compound enzyme based on protease and acid cellulase, wherein protease and acid cellulase account for more than 90% of the total amount of the mixed enzyme, and the consumption ratio of protease and acid cellulase is 7:3. The protease is trypsin.

[0050] Preparation of organic matter: After mixing 2340kg of sludge with a moisture content of 65%, 780kg of peanut bran and 780kg of humic acid, it was ventilated and fermented at room temperature for 3 days.

[0051] Add the compound amino acid hydrolyzate and organic matter into the blender, stir evenly, put it into the reaction roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com