Process for producing furfural from biomass raw material

A biomass raw material, furfural technology, applied in the direction of biofuel, petroleum industry, special dry distillation, etc., can solve the problems of low extraction rate of hemicellulose and low yield of furfural, achieve high cooking efficiency, simple process route, multiple benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

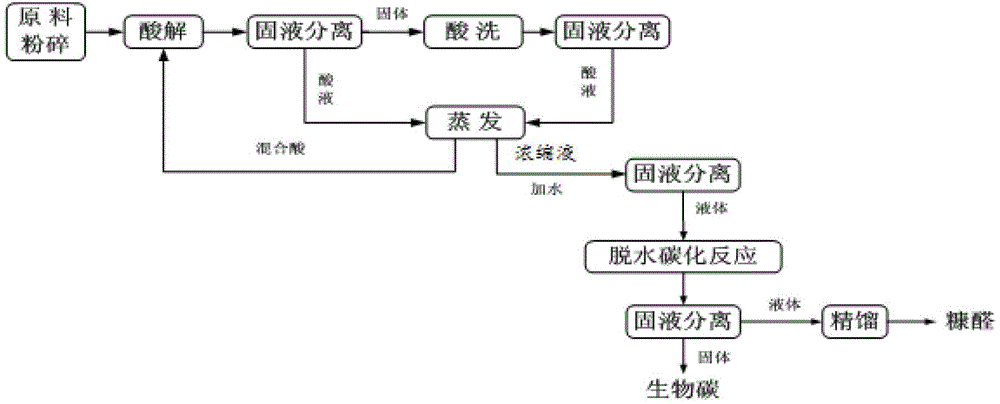

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, the reed is first crushed and crushed to a particle size of 2 cm-10 cm.

[0053] The process for producing furfural from the reed in this embodiment includes the following steps:

[0054] (1) After the reed raw material is crushed and pretreated, under the catalysis of hydrogen peroxide, an organic acid solution with a total acid concentration of 75% by weight is used to cook the treated reed raw material. In this embodiment, the organic acid The mass ratio of acetic acid and formic acid in the liquid is 1:19, and the mass of the hydrogen peroxide accounts for 1 wt% of the mass of the reed raw material.

[0055] Control the reaction temperature at 90°C, react for 90 minutes, the solid-liquid mass ratio is 1:6, and perform the first solid-liquid separation of the obtained reaction liquid;

[0056] (2) Add the solid obtained from the first solid-liquid separation to the mixed acid solution formed by formic acid and acetic acid with a total acid concentration o...

Embodiment 2

[0062] In this embodiment, the bean straw is first crushed and crushed to a particle size of 2-10 cm.

[0063] In this embodiment, the process for producing furfural from the soybean straw includes the following steps:

[0064] (1) After the soybean straw raw material is crushed and pretreated, under the catalysis of hydrogen peroxide, an organic acid solution with a total acid concentration of 70 wt% is used to cook the processed soybean straw raw material. In this embodiment, The mass ratio of acetic acid and formic acid in the organic acid solution is 10:1, and the mass of the hydrogen peroxide accounts for 3 wt% of the mass of the soybean straw raw material.

[0065] The reaction temperature is controlled to 100°C, the reaction is 70 minutes, the solid-liquid mass ratio of the mixed acid solution of formic acid and acetic acid to the biomass raw material is 1:5, and the obtained reaction liquid is subjected to the first solid-liquid separation;

[0066] (2) Add the solid obtained ...

Embodiment 3

[0072] In this embodiment, the straw is first crushed and crushed to a particle size of 2 cm-10 cm.

[0073] The process of producing furfural from the rice straw in this embodiment includes the following steps:

[0074] (1) After the rice straw raw material is crushed and pretreated, under the catalysis of hydrogen peroxide, an organic acid solution with a total acid concentration of 80 wt% is used to cook the treated rice straw raw material. In this embodiment, the organic acid The mass ratio of acetic acid and formic acid in the liquid is 1:1, and the mass of the hydrogen peroxide accounts for 6 wt% of the mass of the straw raw material.

[0075] Control the reaction temperature at 105°C, react for 50 minutes, the solid-liquid mass ratio is 1:8, and perform the first solid-liquid separation of the obtained reaction liquid;

[0076] (2) Add the solid obtained from the first solid-liquid separation to a mixed acid solution composed of formic acid and acetic acid with a total acid con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com