Batch Productivity Improvement Method for Homogeneous Bonding System of Multi-chip Module

A multi-chip component and homogeneous bonding technology, which is applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of no homogeneous bonding system, easy electromigration, and no application for multi-chip components. To achieve the effect of improving the ability to work fully and reliably for a long time, broad market prospects and application space, and improving the manufacturability of large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

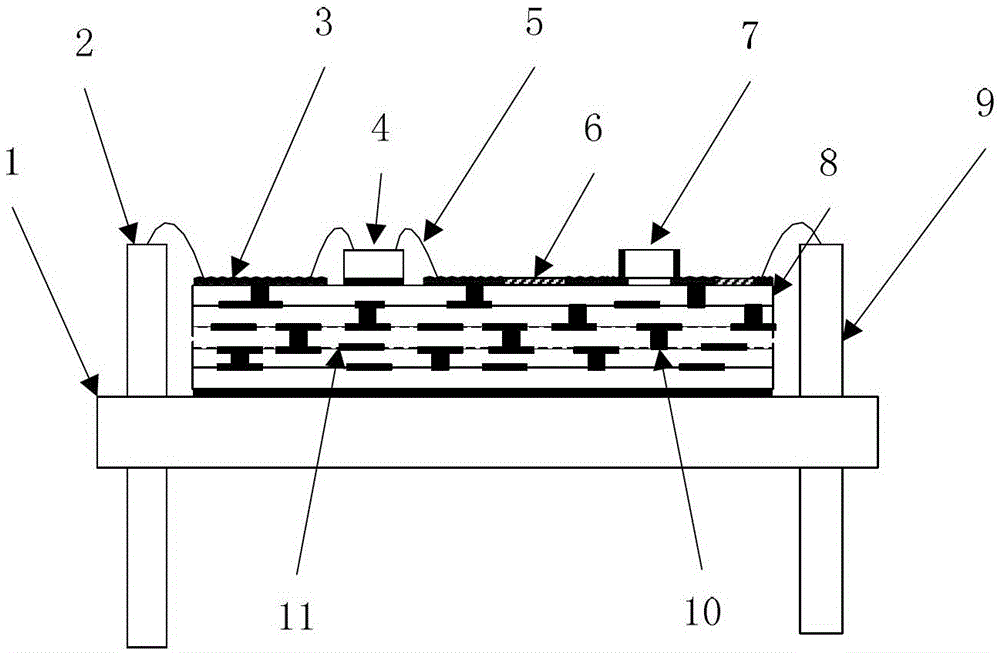

Image

Examples

Embodiment 1

[0018] Example 1 : The original process such as Figure 6 , the process is as follows:

[0019] (1) Material preparation: prepare green ceramic sheets, gold conductor paste, ruthenium resistance paste, semiconductor chips, etc.;

[0020] (2) Cutting: According to the size of the specific product LTCC substrate, cut the pieces according to the requirements;

[0021] (3) Punching: Each layer is interconnected through through holes and conduction bands. Using mechanical punching method, the interconnection path between the ceramic sheets of the LTCC substrate is made according to the graphic and aperture of the product design;

[0022] (4) Hole filling and guide band printing: fill the metal paste into the via holes by screen printing on the ceramic sheet, print out the guide band pattern according to the specified pattern, and dry (150°C, 10min);

[0023] (5) Stopband printing: Print the resistive paste into the stopband pattern according to the specified pattern by screen ...

Embodiment 2

[0037] Example 2: the present invention process such as Figure 7 , add thick film conduction band sintering, mechanical leveling, cleaning and drying processes between thick film conduction band printing and drying and curing, and thick film stop band printing. The added process is as follows:

[0038] (1) Prepare a gold polishing solution with an abrasive grain hardness of 25GPa±5GPa and a particle diameter of 50nm±10nm;

[0039] (2) Conduction band sintering (875°C, 12min, total time 45min);

[0040] (3) Perform one-time chemical mechanical polishing on all gold conduction bands and gold bonding areas with a rotary polishing machine, and the surface flatness is controlled within 0.1 microns;

[0041] (4) Cleaning and drying with deionized water;

[0042] (5) Printing, sintering and resistance adjustment process of resistance paste.

[0043] After the trimming and testing of the thick film resistors, the aluminum metal film deposition process in the gold thick film bondin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com