Method for measuring content of silicon dioxide in iron ores

A silicon dioxide and iron ore technology, applied in the field of detection, can solve the problems of strict requirements, cumbersome operation, and long time consumption, and achieve the effects of low cost, time saving, high accuracy and precision of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

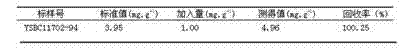

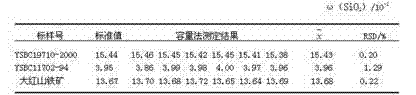

Examples

Embodiment 1

[0017] First prepare the main reagents:

[0018] 0.1mol / L sodium hydroxide standard titration solution: Weigh 110g of AR-grade sodium hydroxide, dissolve it in 100 mL of carbon dioxide-free water, shake well, pour into a polyethylene container, and place it airtight until the solution is clear. Measure 5.4 mL supernatant with a plastic tube, dilute to 1000 mL with carbon dioxide-free water, and mix well. Calibration shall be carried out according to GB / T601.

[0019] Next is to test:

[0020] Weigh about 0.15g of the sample, weighed to an accuracy of 0.0001g, and place it in a 250mL polytetrafluoroethylene beaker. Add 10 mL of nitric acid and 20 mL of hydrofluoric acid, and mix well. Cover the polytetrafluoroethylene watch glass, place the polytetrafluoroethylene beaker on the electric heating plate from low temperature to 180 °C, keep the temperature gently and heat it, shake it every 5 minutes, boil for 20 minutes, control the remaining volume to 10mL and remove it. Afte...

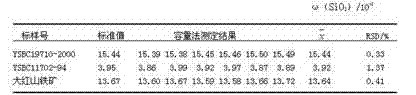

Embodiment 2

[0026] On the basis of the experimental method of embodiment 1,

[0027] Weigh about 0.18g of the sample, weighed to an accuracy of 0.0001g, and place it in a 250mL polytetrafluoroethylene beaker. Add 11 mL of nitric acid and 22 mL of hydrofluoric acid, and mix well. Cover the polytetrafluoroethylene watch glass, put the polytetrafluoroethylene beaker on the electric heating plate and raise it from low temperature to 190 °C, keep the temperature and heat gently, shake once every 5 minutes, slightly boil for 25 minutes, control the remaining volume to 10mL and remove it. After adding 10mL of hydrochloric acid-nitric acid mixed acid, add 2.5g of solid potassium chloride, stir carefully until saturated, and a small amount of solid potassium chloride remains undissolved. Slowly add 9mL potassium fluoride solution under stirring, continue to stir for 1 min, put it in an ice-cold container to cool down rapidly, and place it for about 25 min. Under constant stirring, slowly pour in...

Embodiment 3

[0034] On the basis of the experimental method of embodiment 1,

[0035]Weigh about 0.20g of the sample, weighed to an accuracy of 0.0001g, and place it in a 250mL polytetrafluoroethylene beaker. Add 12 mL of nitric acid and 25 mL of hydrofluoric acid, and mix well. Cover the polytetrafluoroethylene watch glass, place the polytetrafluoroethylene beaker on the electric heating plate from low temperature to 200 °C, keep the temperature gently and heat it, shake it every 5 minutes, boil for 30 minutes, control the remaining volume to 10mL, and then remove it. After adding 10mL of hydrochloric acid-nitric acid mixed acid, add 3g of solid potassium chloride, stir carefully until saturated, and a small amount of solid potassium chloride remains undissolved. Slowly add 10mL of potassium fluoride solution under stirring, continue to stir for 1 min, put it in an ice-cold container to cool down rapidly, and place it for about 30 min. Under constant stirring, slowly pour into a polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com