Method for extracting polymyxin B from fermentation broth

A technology of polymyxin and fermentation liquid, which is applied in the direction of preparation methods of polymyxin and peptides, chemical instruments and methods, etc., and can solve the problems of low purity of polymyxin B, large one-time investment, and easy pollution of resins, etc. problems, to achieve the effects of less drug resistance, shorter time consumption, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

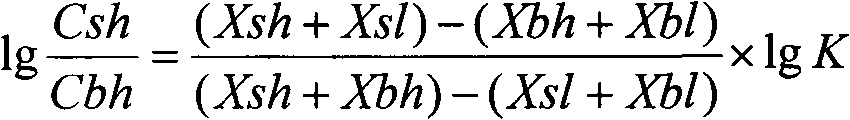

Method used

Image

Examples

Embodiment 1

[0038] a. Fermentation broth pretreatment:

[0039] After the fermentation, a total of 1000 mL of fermented liquid was collected, the titer of polymyxin B was 7.7 IU / mL, the pH was adjusted to 2.3 with sulfuric acid, the fermented liquid was heated to 96° C., and maintained for 45 minutes to obtain a fermentation pretreatment liquid.

[0040] The determination of the potency of the fermentation broth is determined by the tube-and-dish method (with reference to the 2010 edition of "Chinese Pharmacopoeia (Part II)"). The specific method is as follows:

[0041] Indicator bacteria: Bordetella Bronchiseptica, CMCC NO: 58403.

[0042] Incline medium: beef extract 3g; peptone 8g; sodium chloride 5g; glucose 5g; pH 7.0; deionized water 1000mL; agar 22g.

[0043] Test medium: 6g of peptone; 4g of trypticase; 3g of yeast extract; 1.5g of beef extract; 1.0g of glucose; pH6.5~6.7;

[0044] Verification method:

[0045] Pick the well-grown thalli from the slant culture medium, insert i...

Embodiment 2

[0062] The fermentation broth preparation method is the same as in Example 1.

[0063] a. Fermentation broth pretreatment:

[0064] After the fermentation, a total of 1000 mL of fermentation liquid was collected, the titer of polymyxin B was 8.6 IU / mL, the pH was adjusted to 2.0 with sulfuric acid, and the fermentation liquid was heated to 90° C. for 30 minutes to obtain a fermentation pretreatment liquid.

[0065] The fermentation pretreatment liquid is separated into a clear filtrate by solid-liquid separation, and the filtrate is used for extraction.

[0066] b. Extraction:

[0067] Add 480ml of n-butanol to the 1000ml filtrate, mix thoroughly, adjust the pH to 12.0 with sodium hydroxide solution, and transfer the polymyxin B from the filtrate to the extractant. Take the n-butanol extract phase, wash it fully with water, then add an equal volume of water, adjust the pH to 1.6 with sulfuric acid, take the water phase, and obtain 480 ml of an aqueous solution containing pol...

Embodiment 3

[0074] The method and fermentation broth used are the same as in Example 1, except that after adding n-butanol to the filtrate, the pH is adjusted to 12.5 with sodium hydroxide solution to obtain about 648 mg of polymyxin B. Afterwards, about 635 mg of polymyxin B sulfate powder with a purity of 86.3% was obtained, and the titer determined by the tube-and-dish method was 8222 IU / g. The yield was 67.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com