EVA (Ethylene Vinyl-Acetate) glue film special for packaging double glass solar assembly and preparation method thereof

A solar module and film technology, applied in adhesives, electrical components, semiconductor devices, etc., can solve problems such as module defects and safety hazards, and achieve the effect of reducing fluidity, production efficiency, and product cost.

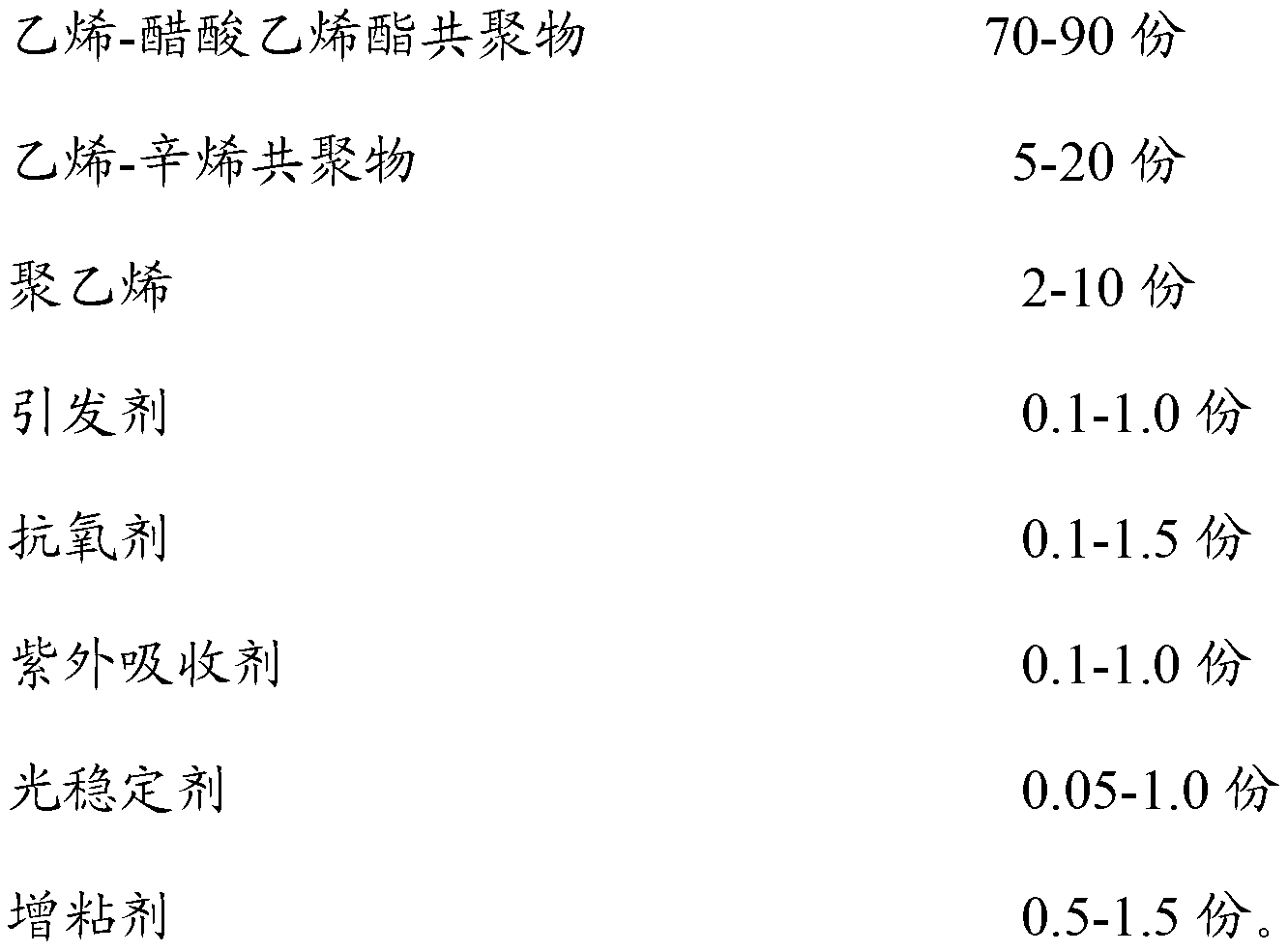

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

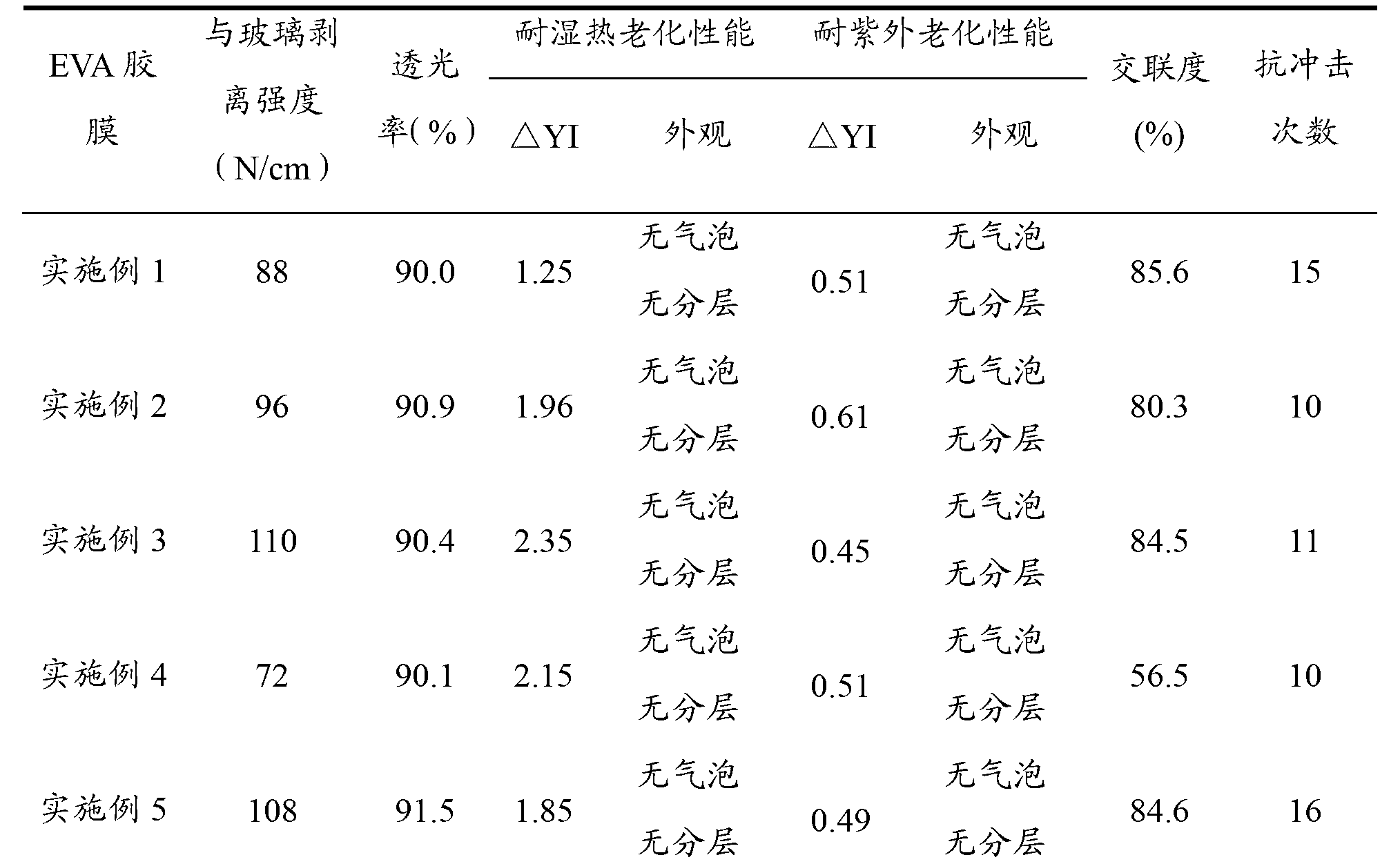

Examples

Embodiment 1

[0027] A special EVA adhesive film for encapsulating double-glass solar modules, prepared by the following method:

[0028] 1) Add 10 parts of ethylene-octene copolymer (POE0210 produced by ExxonMobil, USA) to 80 parts by mass of EVA raw material with a vinyl acetate content of 25% and a melt index of 15g / 10min, and then add 10 parts Polyethylene (SK FT411), 0.6 parts of tert-butyl peroxy 2-ethylhexyl carbonate, 0.5 parts of vinyltrimethoxysilane are mixed evenly, and the grafting pretreatment reaction is extruded through the extruder, The temperature is 155°C, and the extruded product is cooled, pulled, and pelletized into pellet masterbatch.

[0029] 2) Add 1.5 parts of bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, 0.1 parts of 2,4-dihydroxybenzophenone, 0.3 parts of bis-2,2 sebacic acid , 6,6-Tetramethylpiperidinol ester is added to the above masterbatch, mixed evenly, put into the casting machine, and plasticized, extruded, stretched, drawn, and rolled to make EVA glue...

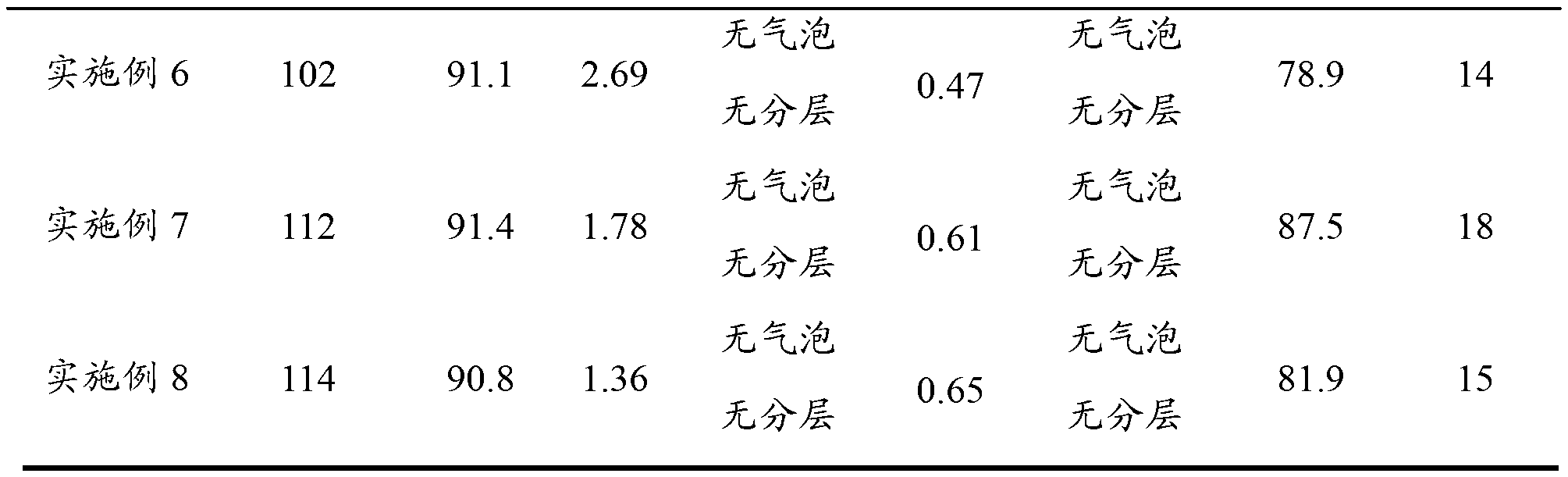

Embodiment 2

[0031] A special EVA adhesive film for encapsulating double-glass solar modules, prepared by the following method:

[0032] 1) Add 5 parts of ethylene-octene copolymer (produced by ExxonMobil, USA, product model POE0210) to 90 parts by mass of EVA raw materials with a vinyl acetate content of 25% and a melt index of 18g / 10min, and then Add 5 parts of polyethylene (manufactured by SK, product model FT411), 1.0 part of dicumyl peroxide, and 0.7 parts of vinyltriethoxysilane, mix well, and carry out grafting pretreatment reaction through the extruder Extrusion, the temperature is 160°C, the extrudate is cooled, drawn, and pelletized into pellet masterbatch.

[0033] 2) Add 0.1 part of 2,6-tertiary butyl-4-methylphenol, 0.4 part of 2-(2-hydroxy-5-methylphenyl)benzotriazole, 0.05 part of sebacic acid bis -2,2,6,6-Tetramethylpiperidinol ester is added to the above masterbatch, mixed evenly, put into the casting machine, and plasticized, extruded, stretched, drawn, and rolled to mak...

Embodiment 3

[0035] A special EVA adhesive film for encapsulating double-glass solar modules, prepared by the following method:

[0036] 1) Add 20 parts of ethylene-octene copolymer (produced by ExxonMobil, USA, product model POE0210) to 70 parts by mass of EVA raw material with a vinyl acetate content of 34% and a melt index of 30g / 10min, and then Add 10 parts of polyethylene (manufactured by SK Company, the product model is FT411), 1.0 parts of 2,5-dimethyl-2,5-bis-(tert-butylperoxy)hexane, 1.5 parts of vinyltrimethoxy After the silane is mixed evenly, it is extruded through an extruder for grafting pretreatment reaction at a temperature of 165°C, and the extruded product is cooled, drawn, and pelletized into a master batch of pellets.

[0037] 2) Add 0.8 parts of bis(3,5-tertiary butyl-4-hydroxyphenyl)sulfide, 1.0 parts of 2,4-dihydroxybenzophenone, 0.3 parts of N,N,-bis(2, Add 2,6,6-tetramethyl-4-piperidinyl)-1,6-hexanediamine into the above masterbatch, mix evenly, put it into the cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com