Method for processing silica powder suitable for electrode material of lithium ion battery

A lithium-ion battery and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of loss of current collector electrical contact, high irreversible capacity, and decreased cycle performance, and achieve improved electrochemical reaction kinetics. The effect of increasing the electrochemical reaction interface and suppressing the volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Microemulsion system preparation: weigh according to the mass ratio, cyclohexane: water: TritonX-100: n-butanol is 100: 40: 55: 20, put it in a beaker, emulsify and disperse with an emulsifier at room temperature, and emulsify with an emulsifier The rotation speed is 5000rpm, and the emulsification time is 5min;

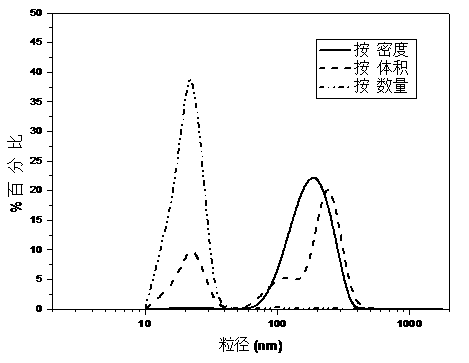

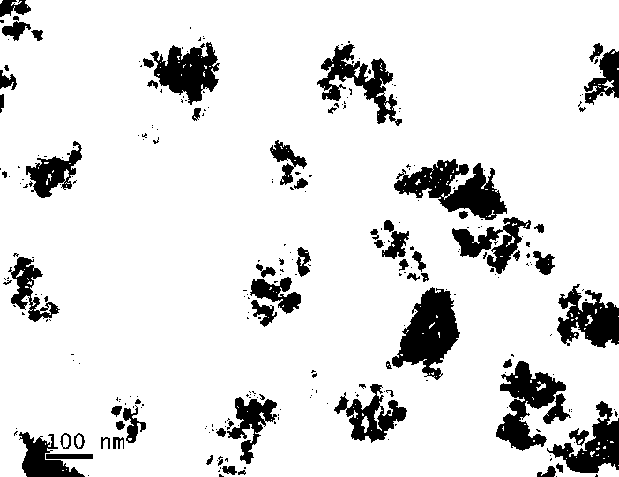

[0025] (2) Microemulsion phase sanding: Weigh 30g of industrial-grade high-purity silicon powder and zirconia grinding beads, add them to 150g of the above microemulsion at a ball-to-material ratio of 50:1, perform microemulsion phase sanding, and control the sanding speed 3000rpm, sanding time is 6h;

[0026] (3) Filtration and washing of materials: After sand milling, first filter the zirconia grinding beads with a filter cloth, then vacuum filter the filtrate through a microporous membrane to separate the microemulsion phase, and finally add an appropriate amount of ethanol to wash the residual emulsion on the surface of the particles ;

[0027] (4) A...

Embodiment 2

[0030] (1) Microemulsion system preparation: weigh according to the mass ratio, n-hexane: water: CTAB: n-butanol is 100: 35: 48: 24, put it in a beaker, emulsify and disperse at room temperature with an emulsifier, and the emulsifier speed is 5000rpm , the emulsification time is 5min;

[0031] (2) Microemulsion phase sanding: Weigh 40g of industrial-grade high-purity silicon powder and zirconia grinding beads, add them to 200g of the above microemulsion at a ball-to-material ratio of 50:1, perform microemulsion phase sanding, and control the sanding speed 3000rpm, sanding time is 8h;

[0032] (3) Filtration and washing of materials: After sand milling, first filter the zirconia grinding beads with a filter cloth, then vacuum filter the filtrate through a microporous membrane to separate the microemulsion phase, and finally add an appropriate amount of ethanol to wash the residual emulsion on the surface of the particles ;

[0033] (4) Atomization and drying forming: use the ...

Embodiment 3

[0036] (1) Microemulsion system preparation: weigh according to the mass ratio, n-heptane: water: CTAB: n-amyl alcohol is 100: 42: 28: 17, put it in a beaker, and emulsify and disperse with an emulsifier at room temperature. 6000rpm, emulsification time is 3min;

[0037] (2) Microemulsion phase sanding: Weigh 40g of industrial-grade high-purity silicon powder and zirconia grinding beads, add them to 150g of the above microemulsion at a ball-to-material ratio of 50:1, perform microemulsion phase sanding, and control the sanding speed 3500rpm, sanding time is 6h;

[0038] (3) Filtration and washing of materials: After sand milling, first filter the zirconia grinding beads with a filter cloth, then vacuum filter the filtrate through a microporous membrane to separate the microemulsion phase, and finally add an appropriate amount of ethanol to wash the residual emulsion on the surface of the particles ;

[0039] (4) Atomization and drying forming: use the atomization and drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com