Rhombus zinc oxide nanorod array and preparation method thereof

A zinc oxide nanorod and rhombus technology is applied in the field of preparation of nanomaterials, which can solve the problems of high price of metal organic chemicals and hydrides, unfavorable large-scale production, poor repeatability, etc. Benefit and social benefit, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

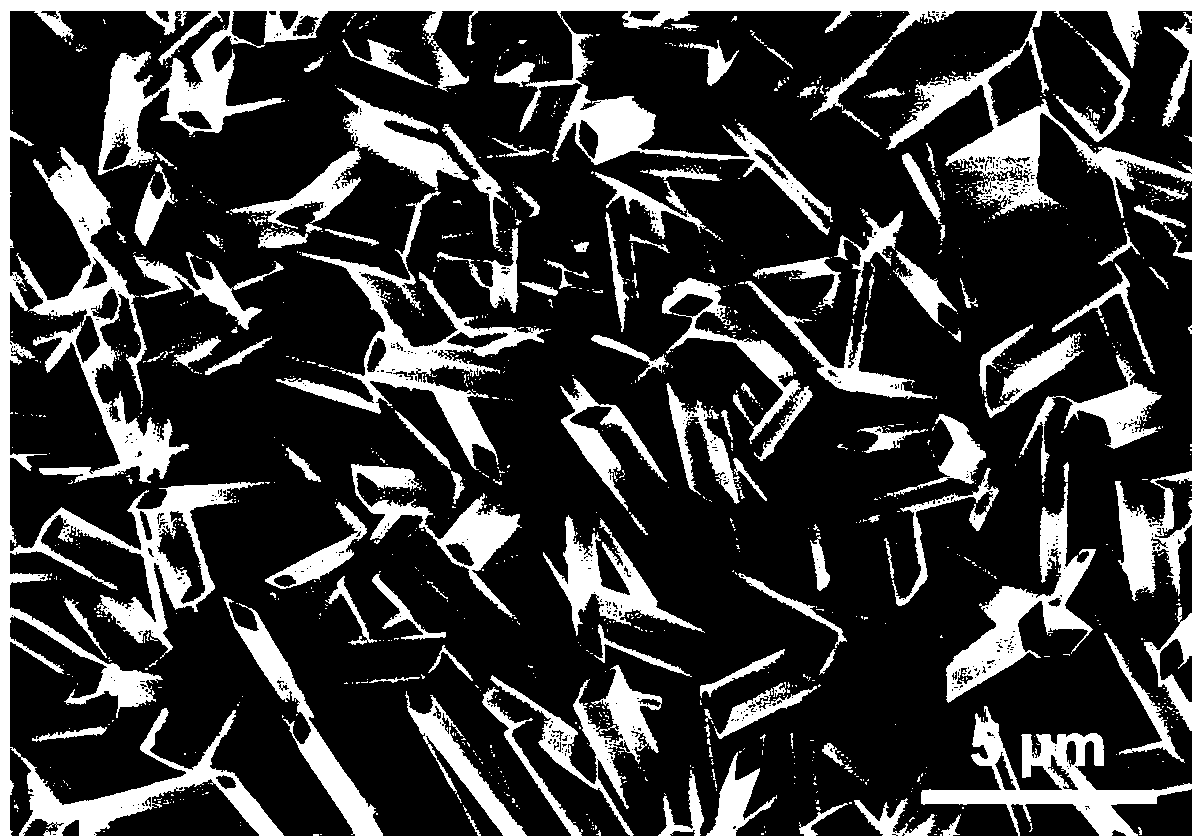

[0035] Mix and stir zinc nitrate, ammonium fluoride, hexamethylenetetramine and water with a molar ratio of 1:1:5 at room temperature to obtain a uniformly mixed solution, and transfer the solution into a stainless steel lined with polytetrafluoroethylene In the high-pressure reaction kettle, the filling degree of the reaction kettle is 50%, and the clean metal nickel substrate is placed in the solution. The hydrothermal reaction temperature is controlled at 95 ° C, and the time is 24 hours. After the reaction is completed, the substrate is taken out and carried out. Rinse and vacuum dry at 60°C to obtain a zinc oxide precursor; then heat treat the zinc oxide precursor in an argon atmosphere at a temperature of 450°C for 4 hours to obtain a diamond-shaped zinc oxide nanorod array. The morphology of the obtained product is as figure 1 low-magnification scanning electron microscope images of figure 2 As shown in the high-magnification scanning electron microscope picture of , ...

Embodiment 2

[0037]Mix and stir zinc acetate, sodium fluoride, hexamethylenetetramine and water with a molar ratio of 1:2:5 at room temperature to obtain a uniformly mixed solution, and transfer the solution into a stainless steel lined with polytetrafluoroethylene In the high-pressure reaction kettle, the filling degree of the reaction kettle is 80%, and the clean quartz substrate is placed in the solution, and the hydrothermal reaction temperature is controlled at 80°C for 12 hours. After the reaction is completed, the substrate is taken out and rinsed , vacuum-dried at 60°C to obtain a zinc oxide precursor; then heat-treated the zinc oxide precursor in an argon atmosphere at a temperature of 300°C for 4 hours to obtain a diamond-shaped zinc oxide nanorod array.

Embodiment 3

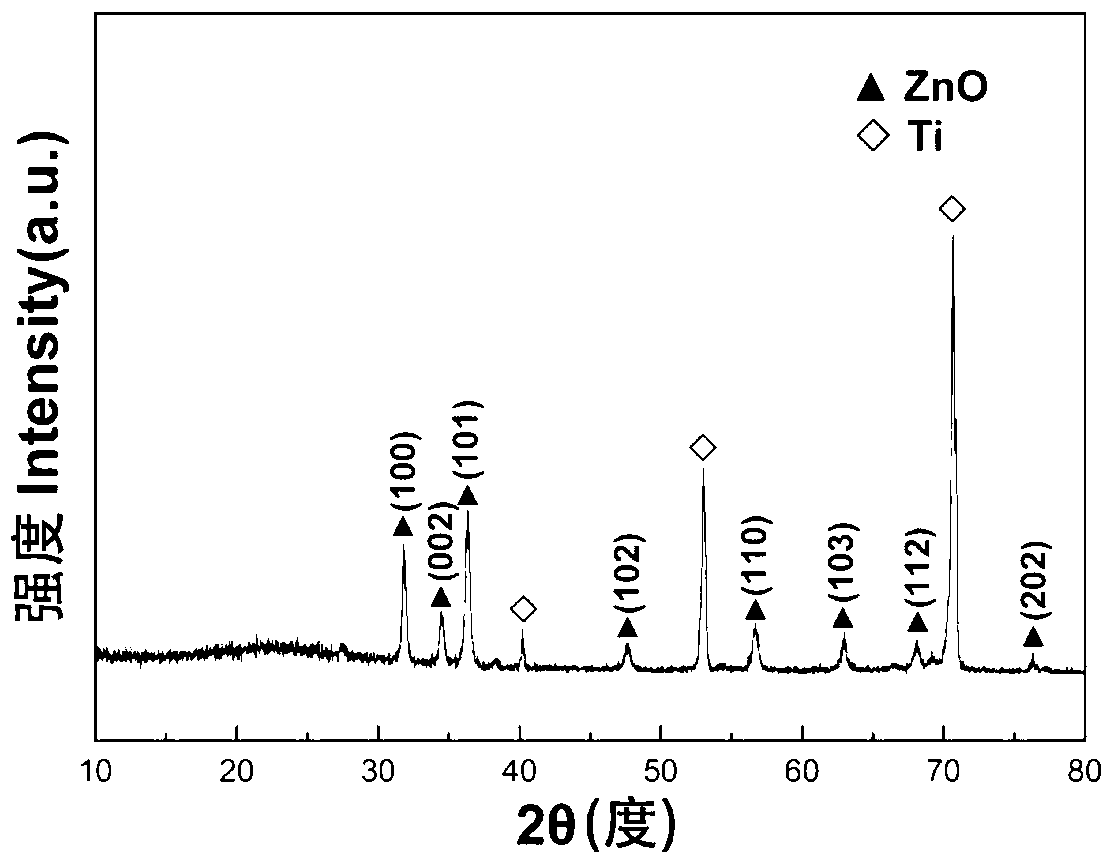

[0039] Mix and stir zinc chloride, potassium fluoride, hexamethylenetetramine and water with a molar ratio of 1:3:5 at room temperature to obtain a uniformly mixed solution, and transfer the solution into a polytetrafluoroethylene-lined In a stainless steel high-pressure reaction kettle, the filling degree of the reaction kettle is 70%, and a clean metal titanium substrate is placed in the solution. The hydrothermal reaction temperature is controlled at 90°C, and the time is 48 hours. After the reaction is completed, the substrate is taken out and Rinse and dry in vacuum at 60°C to obtain a zinc oxide precursor; then heat treat the zinc oxide precursor in a nitrogen atmosphere at a temperature of 400°C for 4 hours to obtain a diamond-shaped zinc oxide nanorod array. image 3 The X-ray diffraction (XRD) pattern of the zinc oxide nanorod array shows that all peaks correspond to pure zinc oxide and there are no miscellaneous peaks. It can be seen that the prepared nanoarray is pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com